Water-based self-cleaning finish-coat paint and preparation method thereof

A finish paint and self-cleaning technology, applied in the field of finish paint, can solve the problems of weather resistance, color retention, water resistance, stain resistance, easy cracking of exterior wall paint film, etc., to achieve excellent adhesion, reinforcement and safety The effect of sex and environmental protection and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

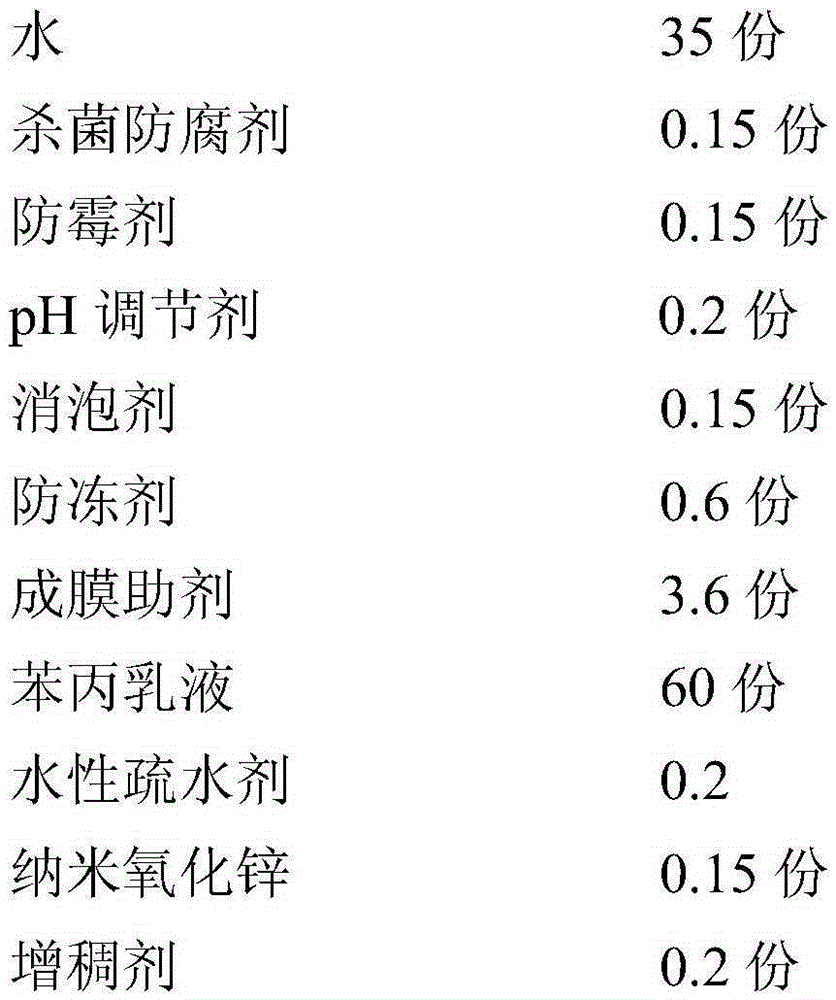

[0024] A water-based self-cleaning finish paint is prepared from the following components and parts by weight ratio:

[0025]

[0026] A preparation method of water-based self-cleaning finish paint, it comprises the following steps carried out in sequence:

[0027] Add 35 parts of water into the dispersion tank, add 0.15 parts of bactericidal preservatives, 0.15 parts of antifungal agents, 0.2 parts of pH regulators, 0.15 parts of defoamers, 0.6 parts of antifreeze and 3.6 parts of ingredients at a speed of 400r / min. Membrane aid, stir for 4 minutes. Then, add 60 parts of styrene-acrylic emulsion and stir for 2 minutes. Next, add 0.2 parts of water-based hydrophobic agent and 0.15 parts of nano-zinc oxide, and finally add 0.2 parts of thickener to adjust the viscosity to 52KU to obtain the product of the present invention.

[0028] Further, the bactericidal preservative in the above components is Sol ActicideRS bactericidal preservative. Described antifungal agent is Tro...

specific Embodiment example 2

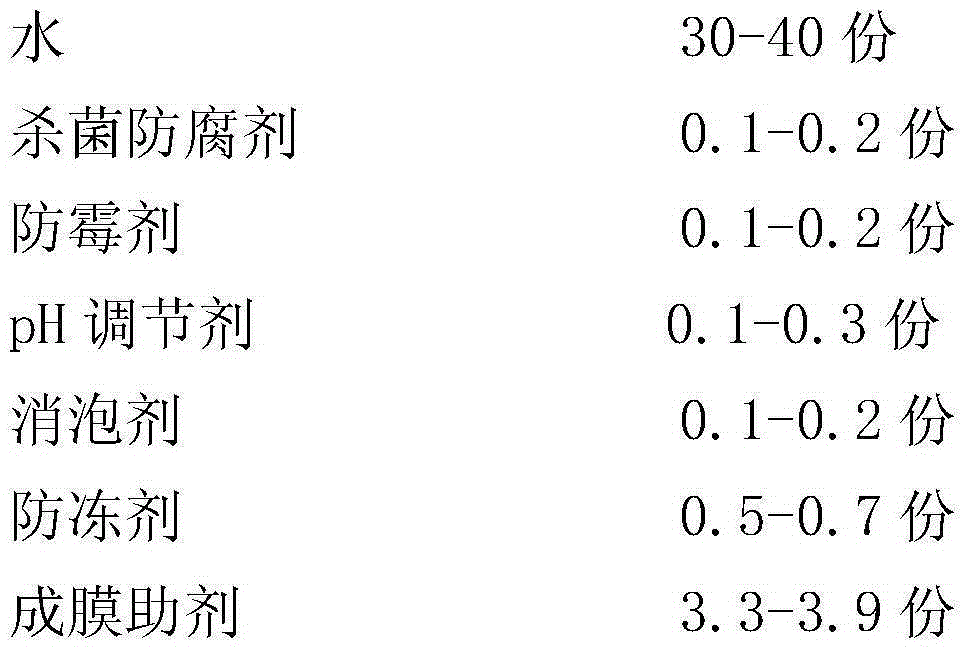

[0030] A water-based self-cleaning finish paint is prepared from the following components and parts by weight ratio:

[0031]

[0032] A preparation method of water-based self-cleaning finish paint, it comprises the following steps carried out in sequence:

[0033] Add 30 parts of water into the dispersing tank, add 0.1 part of bactericidal preservative, 0.2 part of antifungal agent, 0.1 part of pH regulator, 0.1 part of defoamer, 0.7 part of antifreeze and 3.9 parts of ingredients at a speed of 200r / min. Membrane aid, stir for 3 minutes. Then, add 65 parts of styrene-acrylic emulsion and stir for 1 minute. Next, add 0.3 part of water-based hydrophobic agent and 0.1 part of nano-zinc oxide, and finally add 0.1 part of thickener to adjust the viscosity to 50KU to obtain the product of the present invention.

[0034] Further, the bactericidal preservative in the above components is Sol ActicideRS bactericidal preservative. Described antifungal agent is Troy Polyphsae678 ty...

specific Embodiment example 3

[0036] A water-based self-cleaning finish paint is prepared from the following components and parts by weight ratio:

[0037]

[0038] A preparation method of water-based self-cleaning finish paint, it comprises the following steps carried out in sequence:

[0039] Add 40 parts of water into the dispersion tank, add 0.2 parts of bactericidal preservatives, 0.1 parts of antifungal agents, 0.3 parts of pH regulators, 0.2 parts of defoamers, 0.5 parts of antifreeze and 3.3 parts of ingredients at a speed of 600r / min. Membrane aid, stir for 5 minutes. Then, add 55 parts of styrene-acrylic emulsion and stir for 3 minutes. Next, add 0.1 part of water-based hydrophobic agent and 0.2 part of nano zinc oxide, and finally add 0.3 part of thickener to adjust the viscosity to 55KU to obtain the product of the present invention.

[0040] Further, the bactericidal preservative in the above components is Sol ActicideRS bactericidal preservative. Described antifungal agent is Troy Polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com