Repair agent for fluorine polluted soil and repair method for fluorine polluted soil

A technology of polluted soil and remediation methods, which is applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc. Harmful, activity-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

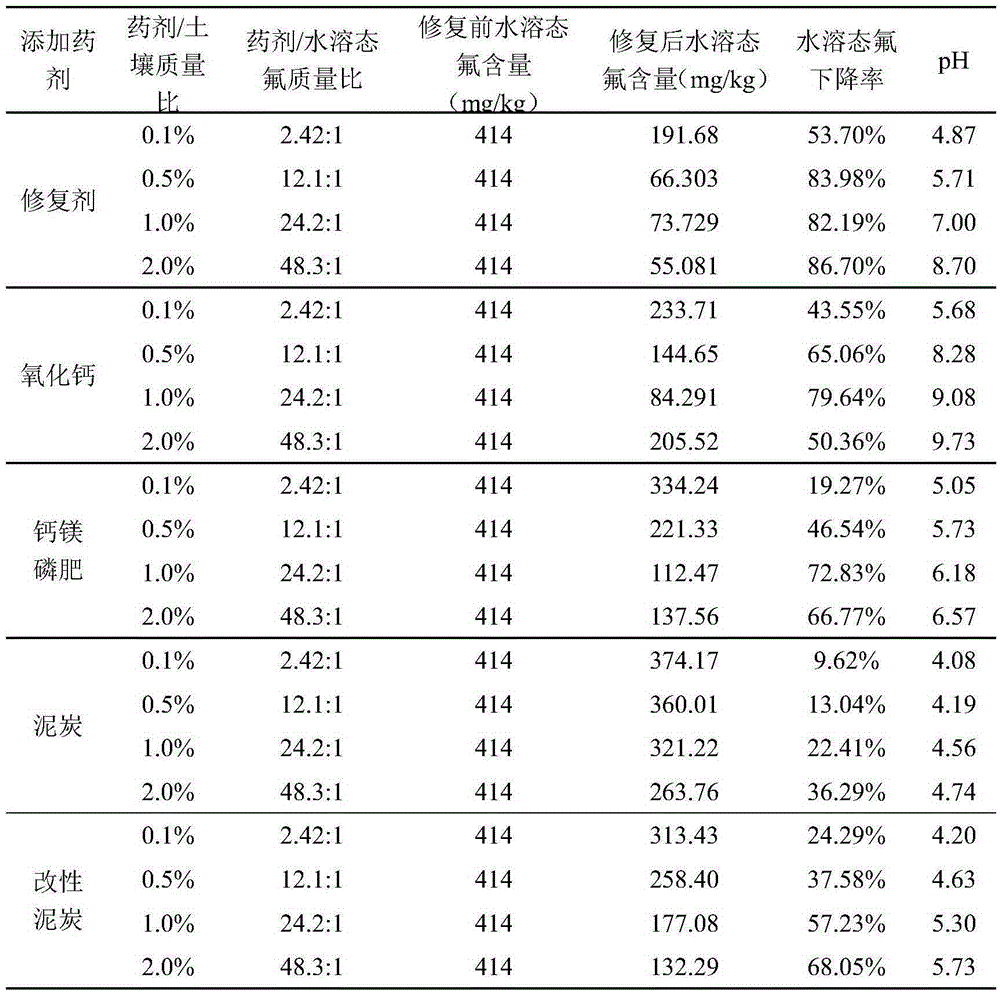

Examples

Embodiment 1

[0028] Weigh 25g of peat, dry it naturally, and grind it through a 60-mesh sieve; add the peat to 150mL of phosphoric acid solution with a concentration of 10mol / L, and heat it in a boiling water bath for 2h; filter the solution obtained by suction, and use deionized water to filter the Wash the obtained solid until the solution is neutral; dry the filtered solid in an oven at 105°C, after drying, grind the obtained solid through a 60-mesh sieve; weigh 20g of the solid powder obtained in the previous step, and add it to 5g / L 200mL of polyaluminum chloride solution, stirred and reacted at 80°C for 2h; the solution obtained from the reaction was subjected to suction filtration, and the solid obtained by suction filtration was dried in an oven at 105°C. After drying, the obtained solid was ground and passed through a 60-mesh sieve ( That is, the particle size of the particles is less than or equal to 250 μm) to obtain modified peat. Phosphoric acid modification will attach part o...

Embodiment 2

[0031] Weigh 25g of peat, dry it naturally, and grind it through a 60-mesh sieve; add the peat to 150mL of phosphoric acid solution with a concentration of 8mol / L, and heat it in a boiling water bath for 2h; filter the solution obtained from the reaction, and filter it with deionized water. Wash the obtained solid until the solution is neutral; dry the filtered solid in an oven at 105°C, after drying, grind the obtained solid through a 60-mesh sieve; weigh 20g of the solid powder obtained in the previous step, and add it to 5g / L 200mL of polyaluminum chloride solution, stirred and reacted at 80°C for 2h; the solution obtained from the reaction was suction filtered, and the solid obtained by suction filtration was dried in an oven at 105°C. After drying, the obtained solid was ground and passed through a 60-mesh sieve to obtain Modified peat.

[0032] Weigh 10g of the above-prepared peat, 10g of calcium magnesium phosphate fertilizer, and 80g of calcium carbonate, mix and grind...

Embodiment 3

[0034] Weigh 40g of peat, dry it naturally, and grind it through a 60-mesh sieve; add peat to 200mL of phosphoric acid solution with a concentration of 10mol / L, and heat it in a boiling water bath for 2h; filter the solution obtained by suction, and filter it with deionized water. Wash the obtained solid until the solution is neutral; dry the filtered solid in an oven at 105°C, after drying, grind the obtained solid through a 60-mesh sieve; weigh 30g of the solid powder obtained in the previous step, and add it to 5g / L 200mL of polyaluminum chloride solution, stirred and reacted at 80°C for 2h; the solution obtained from the reaction was suction filtered, and the solid obtained by suction filtration was dried in an oven at 105°C. After drying, the obtained solid was ground and passed through a 60-mesh sieve to obtain Modified peat.

[0035] Weigh 25g of peat, 25g of calcium magnesium phosphate fertilizer, and 50g of calcium hydroxide prepared above, mix and grind, pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com