Polycrystalline diamond compact bit with four blades

A technology of polycrystalline diamond and composite disc drill bit, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., and can solve problems such as vortex easily generated by combined force centripetal force drill bit, shock vibration in the direction of force, improper arrangement of mud discharge groove, etc. Achieve the effects of improving anti-whirling performance, balancing force, and improving drilling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the drawings:

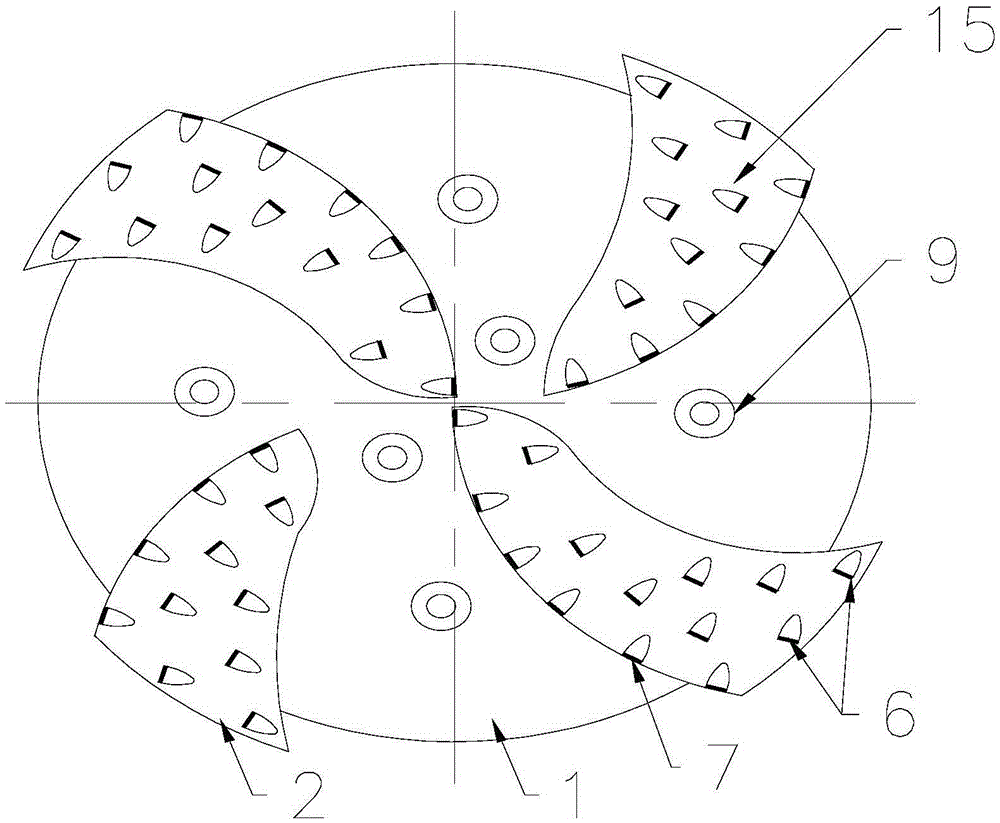

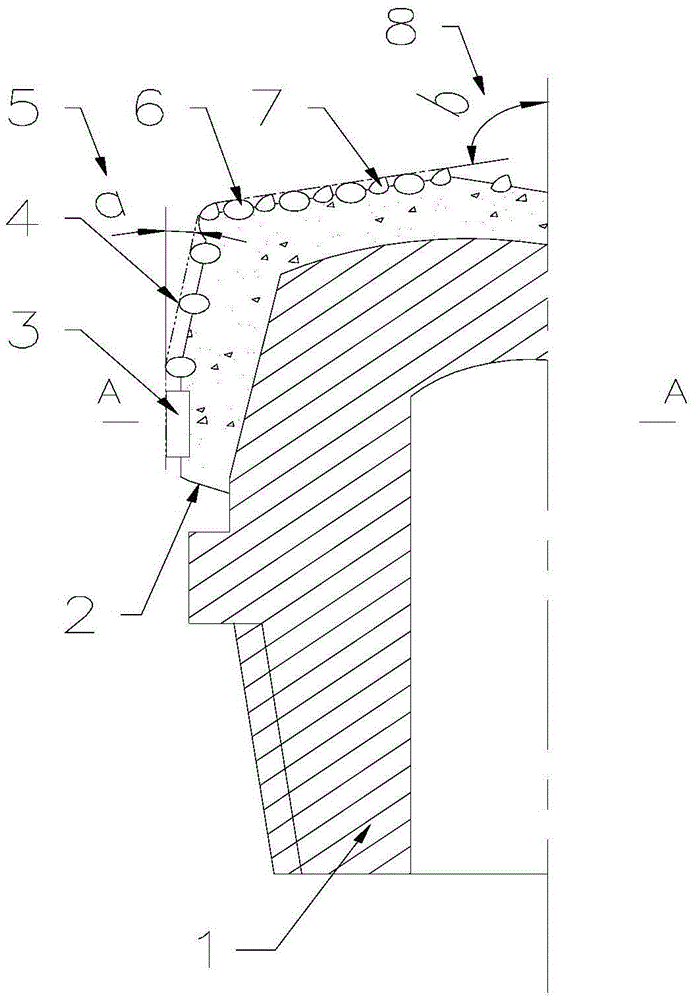

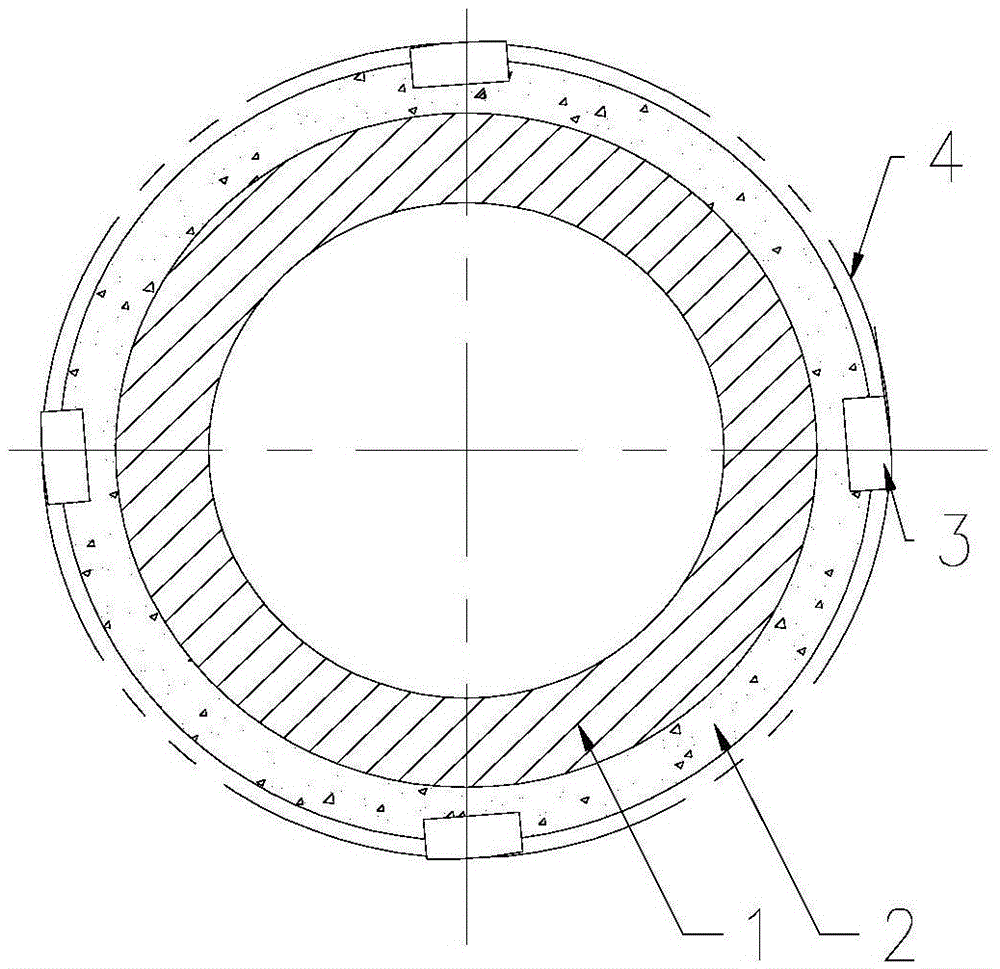

[0016] by figure 1 Combine Figure 2 ~ Figure 6 As shown, the four-blade polycrystalline diamond composite drill bit includes a bit body 1, and two main blades 2 and two auxiliary blades 15 are evenly distributed on the semi-spherical drill crown of the bit body 1. The contours of the cutting surfaces of the wing 2 and the two auxiliary blades 15 are circular arcs. The vertex of the circular arc is tangent to the center line of the drill body 1, and the deviation direction from the circular arc to the outer circle of the drill is the same as the rotation of the drill. In the opposite direction, the direction and shape of the back of the two main blades 2 and the two auxiliary blades 15 are similar to the cutting surface; in terms of tooth arrangement, the principle of tooth arrangement of the entire blade 2, 15 is that the closer to the center of the drill, the cutting teeth are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com