Ultrasonic-electromagnetic combined action based viscosity-reducing and paraffin-control device for crude oil and viscosity-reducing and paraffin-control method of device

A compound action and electromagnetic technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of poor viscosity reduction effect, high labor intensity, pollution of the environment, etc., and achieve convenient and quick installation and low labor intensity , non-polluting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

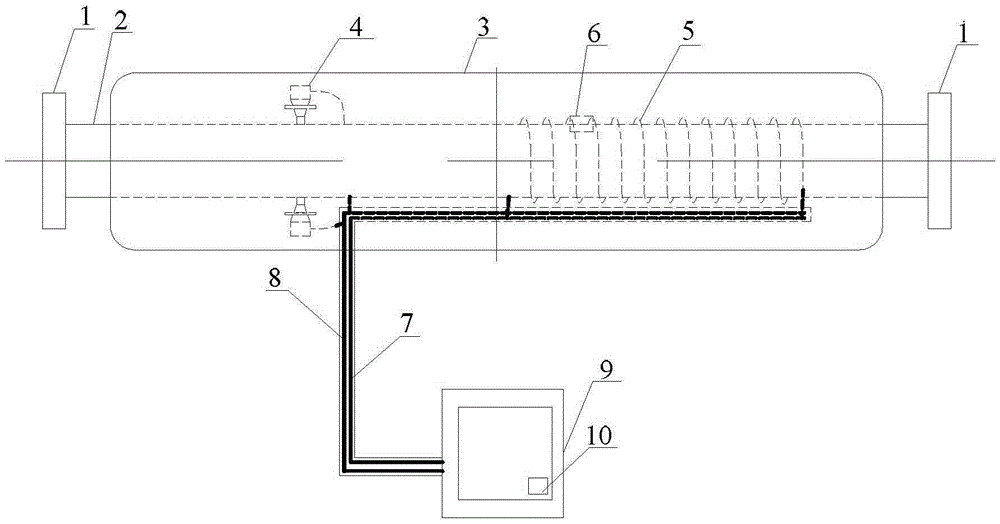

[0016] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. The crude oil viscosity reduction and anti-wax device based on ultrasonic electromagnetic composite action described in this embodiment is applied to the oil pipeline. Sections of oil pipes 2 are fixedly connected by flanges 1, and the feature is that the anti-wax device includes a housing 3, two ultrasonic transducers 4, an inductance coil 5, a first cable 8, a control system 9 and an oscillation circuit 10,

[0017] The outer wall of the tubing 2 is provided with an ultrasonic action part and an electromagnetic action part,

[0018] The ultrasonic action part is provided with two ultrasonic transducers 4, and the two ultrasonic transducers 4 are pasted on the outer wall of the oil pipe 2, and the two ultrasonic transducers 4 are in opposite positions, and the outer wall of the oil pipe 2 of the electromagnetic action part is wound with an inductor The coil 5, the shell 3 is wrappe...

specific Embodiment approach 2

[0024] Specific embodiment 2: This embodiment is a further description of the crude oil viscosity reduction and anti-wax device based on ultrasonic electromagnetic composite action described in specific embodiment 1. In this embodiment, it also includes two temperature sensors 6, one of which has a temperature The sensor 6 is in contact with the inductive coil 5, the temperature signal output end of one temperature sensor 6 is connected to the temperature signal input end of the control system 9, and the other temperature sensor 6 is arranged inside the control system 9, and the temperature signal output of the other temperature sensor 6 is The terminal is connected to the temperature signal input terminal of the oscillating circuit 10.

[0025] In this embodiment, two temperature sensors 6, one of which is located in the electromagnetic action part of the housing 3, its detection end is in contact with the inductance coil 5, and the other temperature sensor 6 is located in the...

specific Embodiment approach 3

[0026] Specific embodiment three: This embodiment is to further explain the crude oil viscosity reduction and anti-wax device based on ultrasonic electromagnetic composite action described in specific embodiment one or specific embodiment two. In this embodiment, the inductance coil 5 is made of enamelled copper The enamelled copper wire is wound on the outer wall of the oil pipe 2 for 20-50 layers, and each layer is wound for 200-800 turns, and a layer of insulating paper is placed between adjacent two layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com