Air source flexible water chiller-heater unit and operation method

A cold and hot water unit and air source technology, which is applied in the operation mode of the machine, refrigerator, refrigeration components, etc., can solve the problems of ordinary cooling towers that cannot extract heat, lack of suitable low-grade heat sources, and insufficient heat extraction. The effect of heating problems in winter, avoiding high solution costs, and reliable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Structure, principle and mode of operation of the present invention are further elaborated below in conjunction with accompanying drawing:

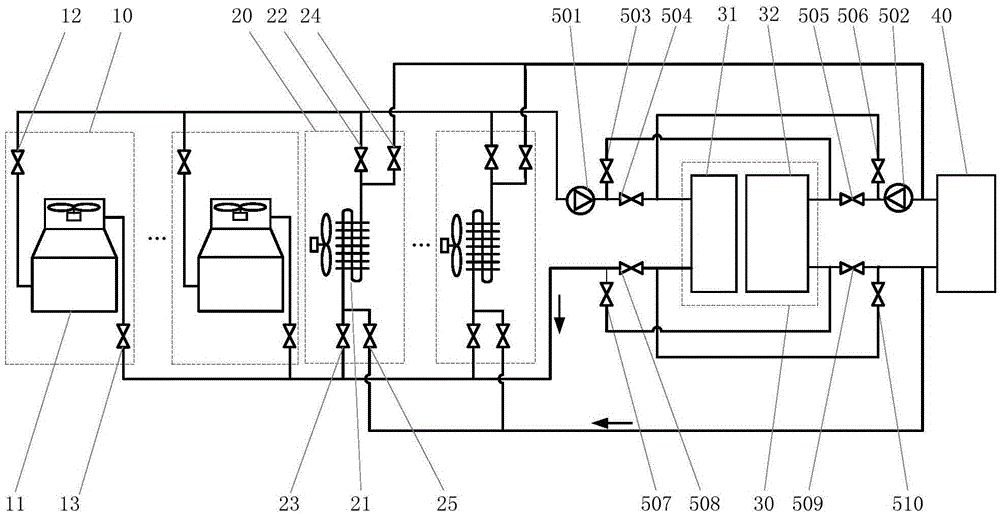

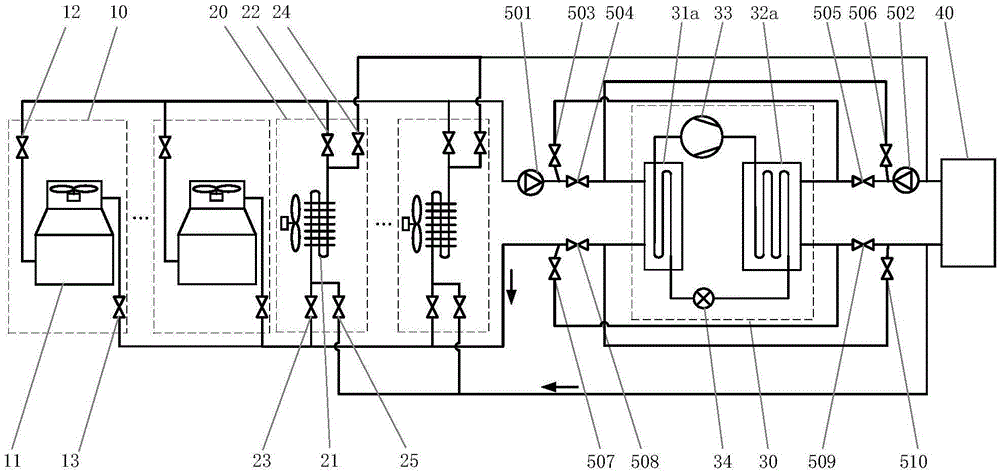

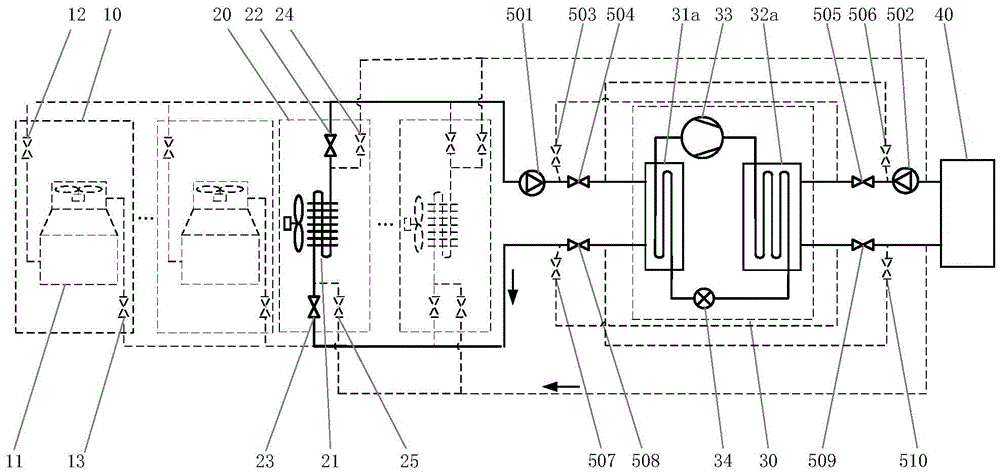

[0034] figure 1 It is a structural schematic diagram of an air source flexible cold and hot water unit disclosed by the present invention. The air source flexible cold and hot water unit of the present invention includes three parts: an outdoor unit, a cold and hot water unit 30 and a user 40; At least one evaporative cooling heat exchange unit 10, at least two outdoor air-cooled heat exchange units 20, and the first liquid pump 501, the second liquid pump 502, the first valve 503, the second valve 504, the third valve 505, the fourth Valve 506, fifth valve 507, sixth valve 508, seventh valve 509 and eighth valve 510; each evaporative cooling heat exchange unit 10 includes a cooling tower 11, a ninth valve 12 located in the outlet pipeline of the cooling tower 11 and a valve located in The tenth valve 13 of the inlet pipeline of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com