Cooling and drying device for biomass briquette fuel and method thereof

A technology for cooling, drying, and forming fuel, which is applied in the directions of biomass drying, drying gas arrangement, and packaging item types. The effect of rapid temperature drop and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

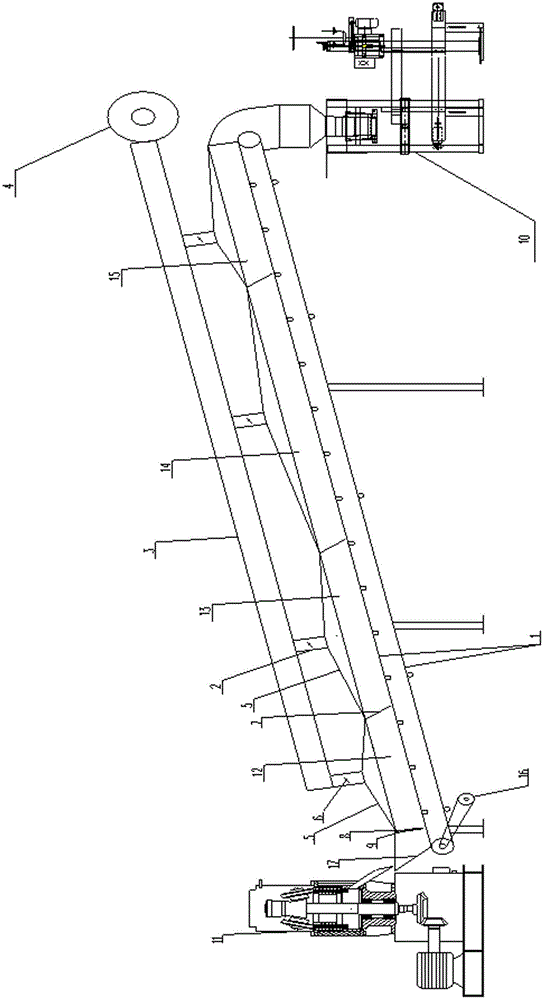

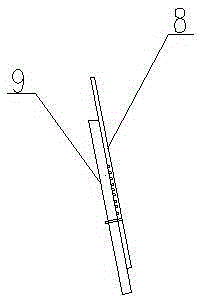

[0025] A biomass briquette fuel cooling and drying device, such as figure 1 with figure 2 As shown, it includes the box body and the material conveyor 1 inclinedly arranged under the box body. The inclination angle of the material conveyor 1 is 30°, the conveyor belt on it is provided with holes, and the two ends of the box body are provided with input ports and output ports. , the input port is located at the lower end of the material conveyor 1, the input port is composed of a longitudinally arranged strip plate 8 and a movable baffle 9, a row of threaded holes is provided on the strip plate 8, and the movable baffle 9 is fixed on the strip plate by screws 8, the output port is located at the upper end of the material conveyor 1, and the outside of the input port is provided with a feed hopper 17, and the box body is divided into 4 independent cooling and drying chambers by a partition plate 7, and the cooling and drying chamber includes the first cooling and drying chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com