Laser-displacement-sensor-based journal axle center measurement apparatus, and measurement and calibration methods thereof

A technology of laser displacement and measuring device, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of high measurement accuracy, small measuring range, and high measurement environment requirements, and achieves large measuring range, high measurement accuracy, and convenient operation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The laser displacement sensor-based journal shaft center measurement device and measurement calibration method of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

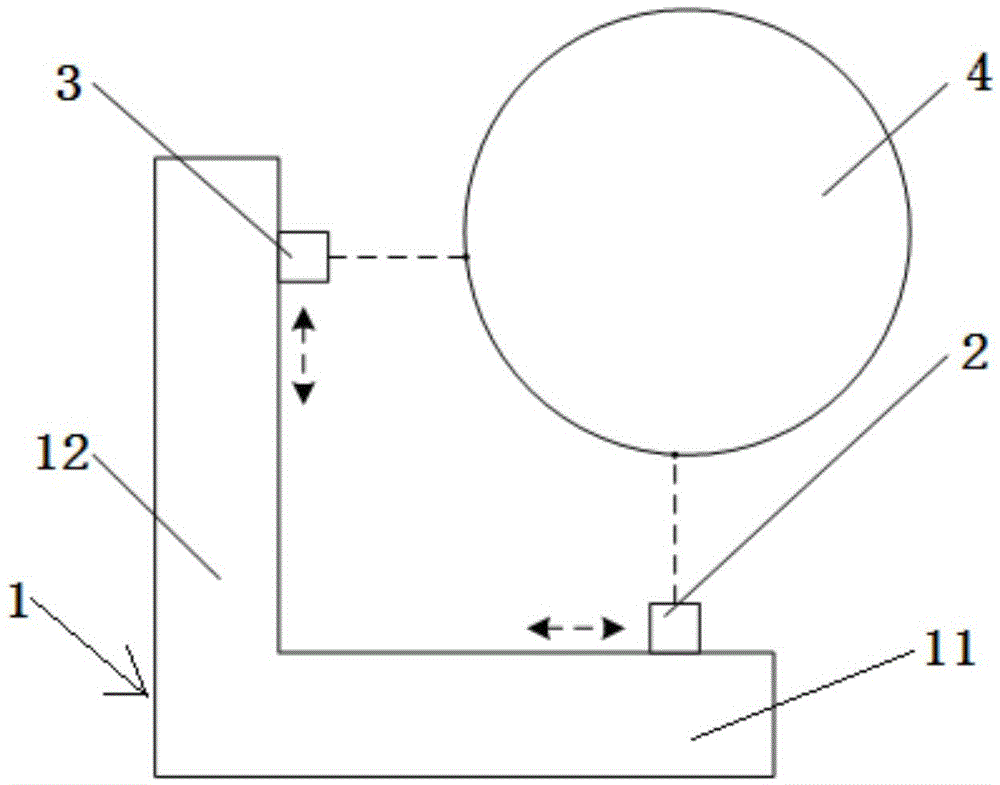

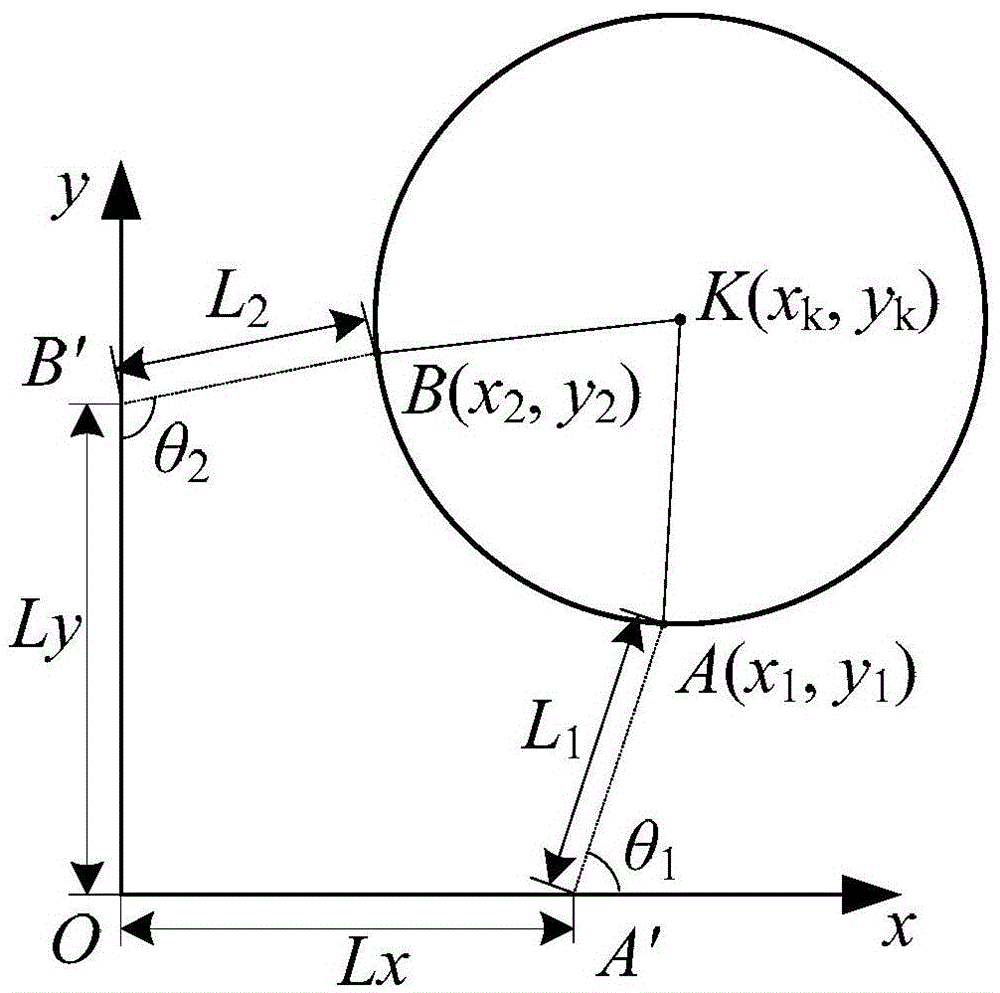

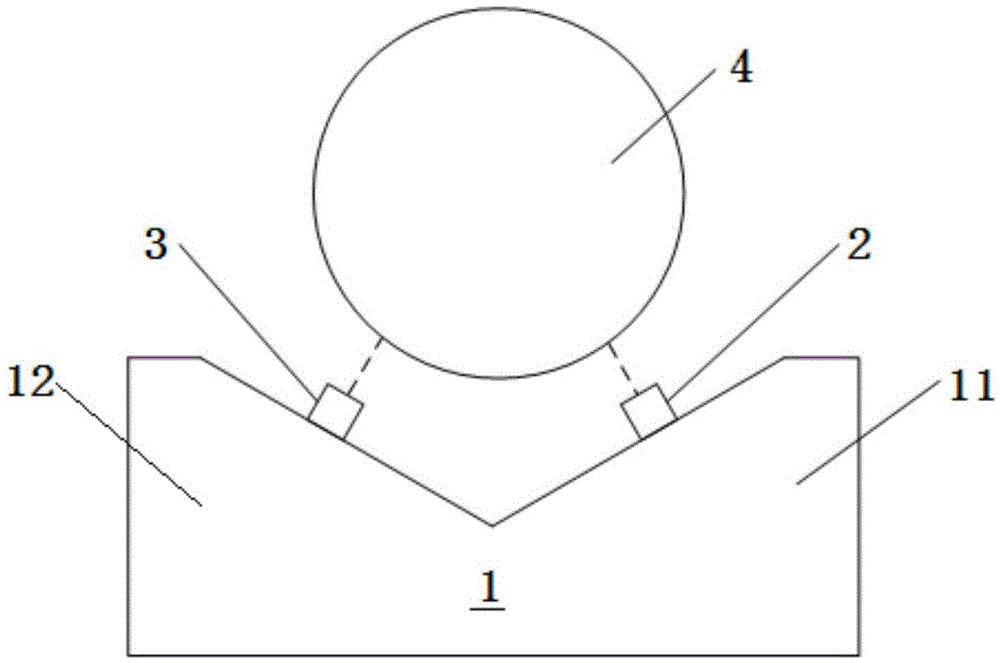

[0052] Such as figure 1 , figure 2 As shown, the journal shaft center measurement device based on the laser displacement sensor of the present invention includes a measurement device for being arranged on the side of the journal 4 of the fixed shaft part for measuring the journal 4 of the shaft part. Frame 1, the measuring frame 1 is composed of a horizontal support 11 with a horizontal plane and a vertical support 12 with a non-horizontal plane, and the horizontal plane of the horizontal support 11 is connected with the non-horizontal support 12 of the vertical support 12. The plane forms an included angle greater than 0 degrees and less than 180 degrees, such as figure 1 Shown is the structural schematic view when the angle formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com