High-precision ceramic pressure sensor

A pressure sensor, high-precision technology, applied in the direction of fluid pressure measurement, instrumentation, and measurement force using capacitance changes, it can solve the problems of poor sensor transmission sensitivity, sensor failure, electrode short circuit, etc., and achieve accurate electrode spacing control, sealing Good connection effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

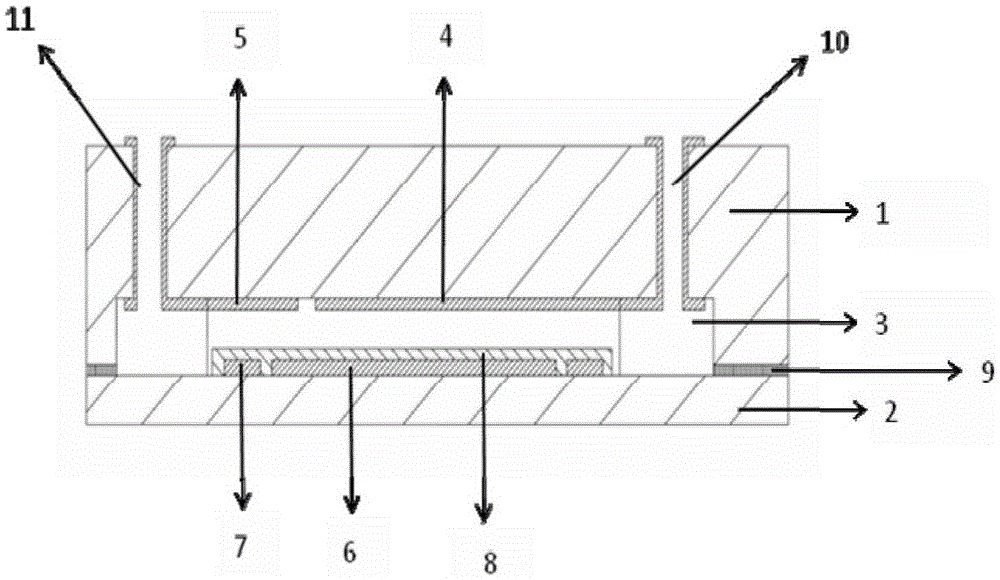

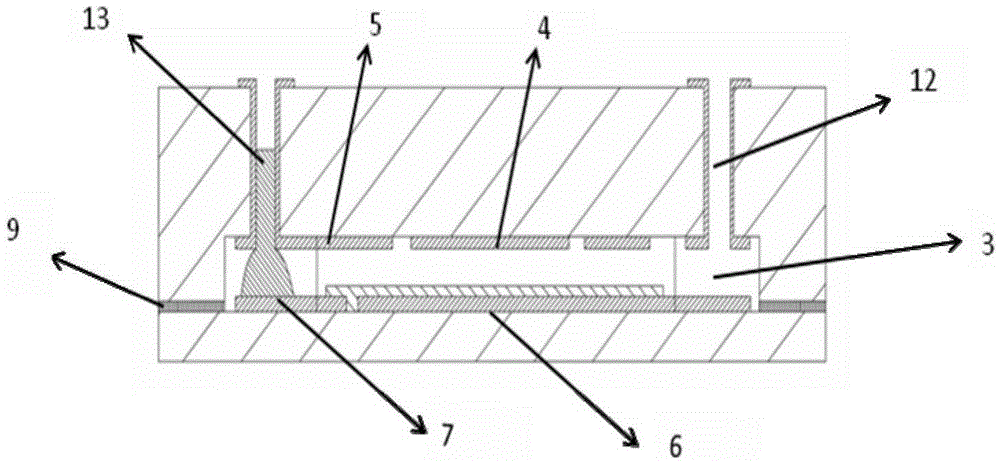

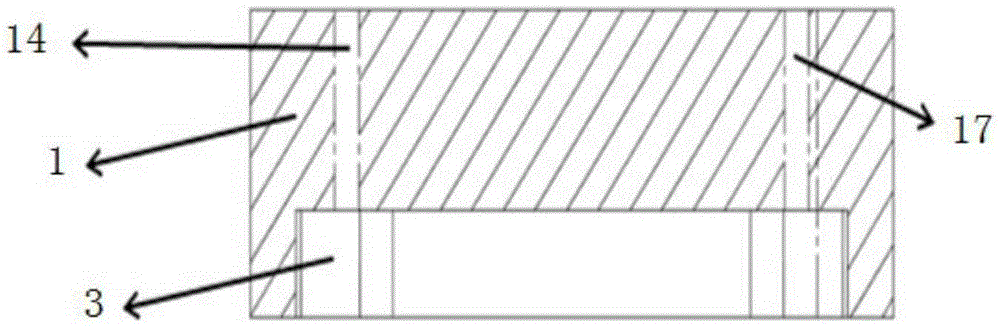

[0028] see Figure 1 to Figure 5 , in some embodiments, a high-precision ceramic pressure sensor includes a ceramic substrate 1 having a cavity 3 and a plurality of conductive vias 10, 11, 12, 13, and a ceramic substrate 1 where the cavity 3 is combined On the ceramic sheet 2 on that side, the concave surface of the cavity 3 is provided with a measuring electrode 4 and a first ring electrode 5 surrounding the measuring electrode 4, and the ceramic sheet 2 is provided with a moving electrode 6 and a surrounding moving electrode on the opposite side of the concave surface. 6 of the second ring electrode 7, the electrode leads 14, 16, 18, 19 of the measuring electrode 4, the first ring electrode 5, the moving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com