High-throughput seed automatic sampling and positive seed selection system and method

A high-throughput, seed-based technology, applied in sampling devices, sorting, etc., can solve problems such as difficulty in obtaining useful sample volume, low impact on sampling accuracy, and dependence on staff skills, so as to avoid sample number errors and shorten selection Time, the effect of reducing storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the drawings and embodiments.

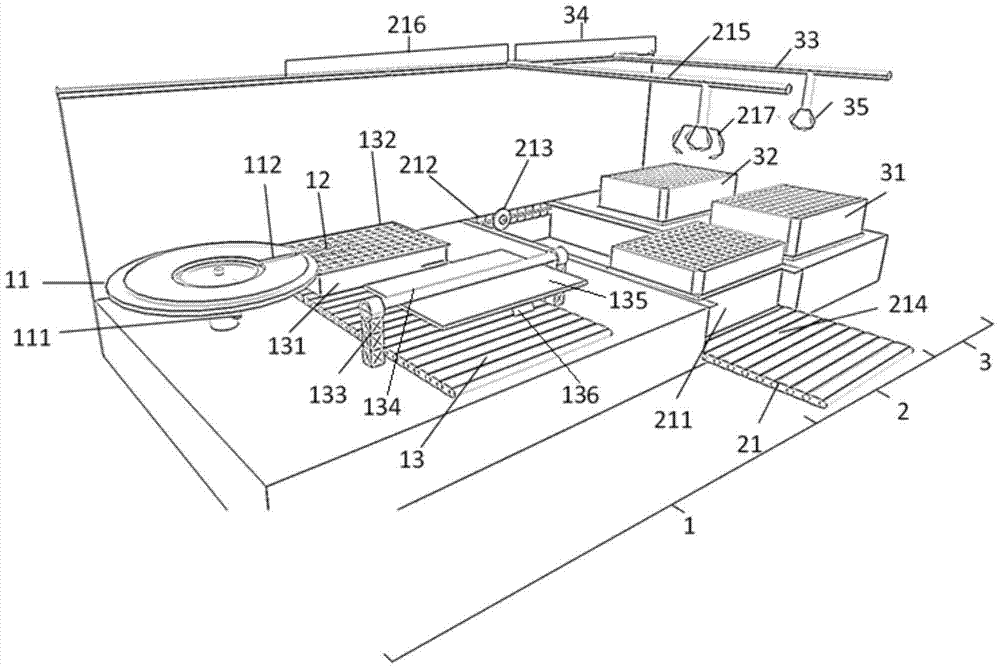

[0025] Such as figure 1 As shown, the high-throughput seed automatic sampling and positive seed selection system of the present invention includes an operating platform and an online computer for controlling the operating platform. Among them, the surface of the operating platform is provided with three operating areas, the seed metering area 1, the sampling area 2, and the storage area 3, and a device protection cover (not shown in the figure) for ensuring the safety of the operator is provided outside the operating platform.

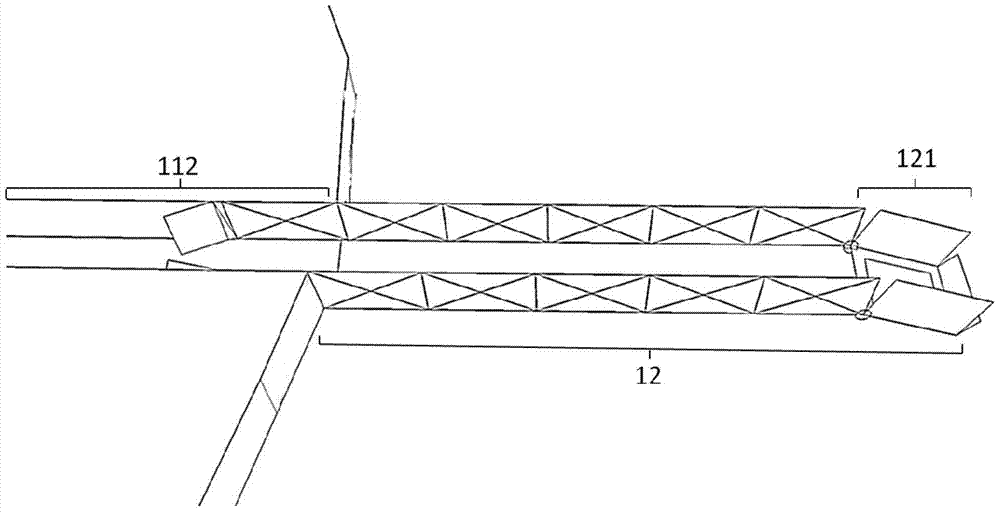

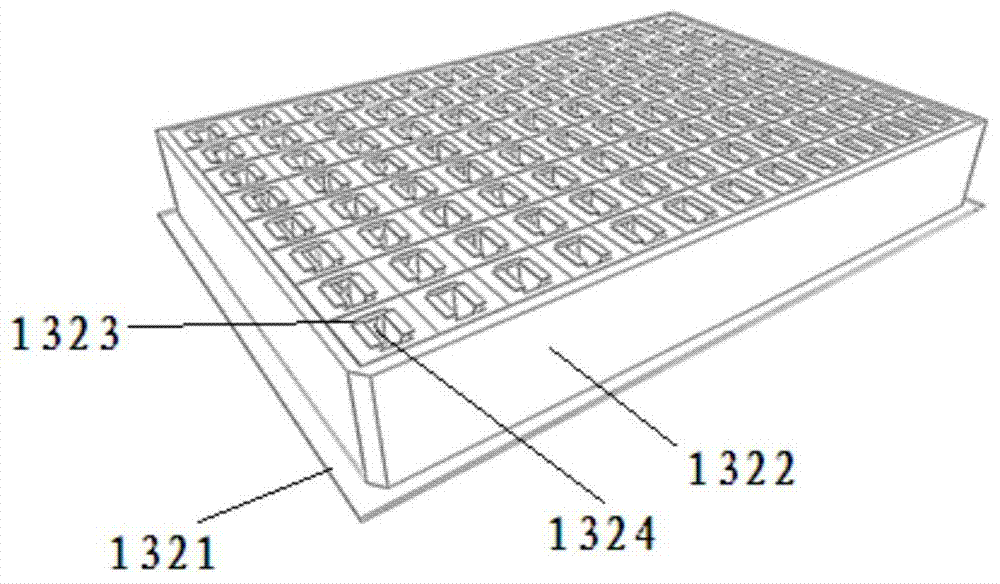

[0026] The surface of the seeding area 1 is provided with a seed vibrating disk 11, a seed conveyor belt 12 and a seed box transmission track 13. The bottom of the seed vibrating plate 11 is provided with a seed discharge port 111 for discharging wrong seeds, and the surface of the seed vibrating plate 11 is provided with a seed vibrating plate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com