Monitoring system and method for heat transfer characteristic of water wall tube of utility boiler

A technology of water-cooled wall tubes and heat transfer characteristics, which is applied in the field of monitoring system for heat transfer characteristics of water-cooled wall tubes of power plant boilers, can solve problems such as poor combustion control and over-temperature of water-cooled walls, improve safety and economy, and prevent Effect of overheating, improving safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

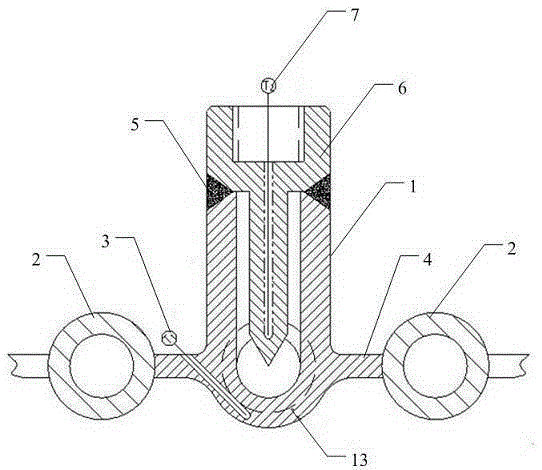

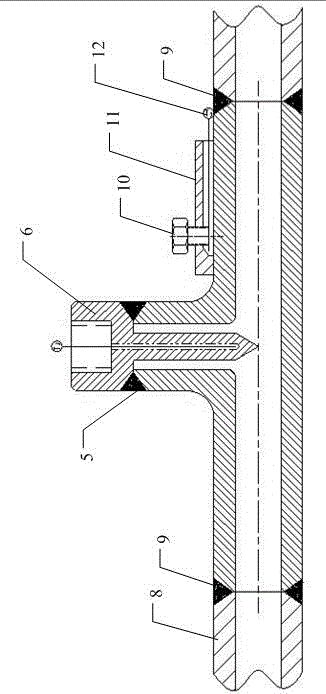

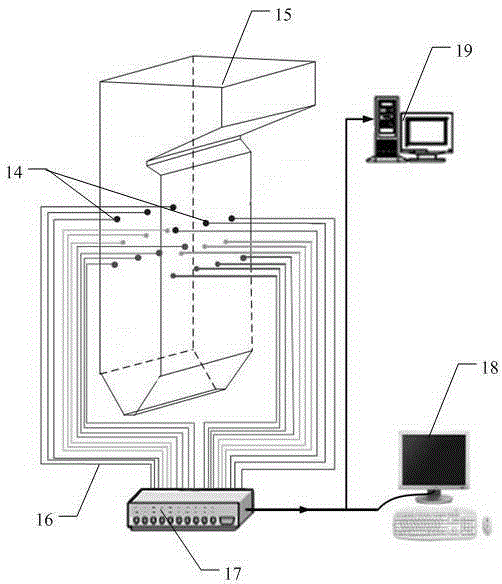

[0022] see figure 1 , 2 , 3. The present invention relates to a monitoring system for the heat transfer characteristics of boiler water wall tubes in a power station, including a boiler 15 installed at different positions on the water wall tubes of the boiler for monitoring the heat transfer characteristics of the water wall tubes 14, a data transmission line 16, and a data collector 17, data display 18 and combustion control computer 19 in the furnace; wherein, each water-cooled wall tube heat transfer characteristic monitoring device, see figure 1 and figure 2 , including the temperature measuring element 3 on the fire side wall of the boiler water wall, the tee piece 1, the plug-in head 6, the working fluid temperature measuring element 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com