Thermal control method of lunar surface patroller six-wheel rocker arm type moving mechanism

A mobile mechanism and patrol technology, applied in non-electric variable control, instrument, temperature control and other directions, can solve the problems of process difficulty, inability to meet the needs of use, and inability to use a low absorption radiation ratio thermal control coating, etc., to achieve high emission efficiency, good adaptability to the space environment, and the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

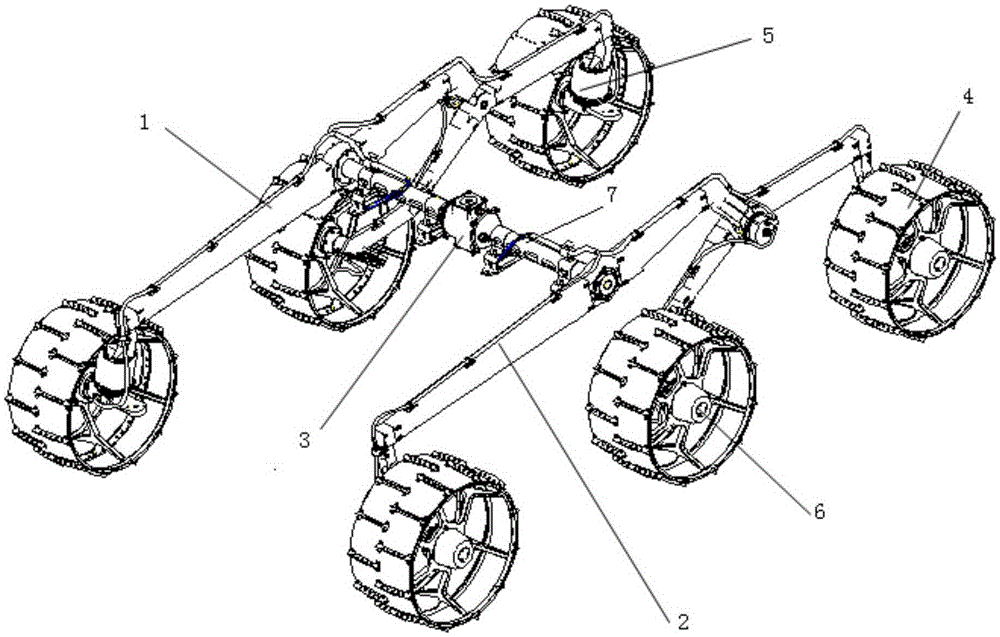

[0029] Please refer to figure 1 and figure 2 , the present invention provides a thermal control method for a six-wheel rocker-arm moving mechanism of a lunar surface patrol device, which is used to control the temperature of the six-wheel rocker-arm moving mechanism. The structure of the moving mechanism is driven by six wheels. The six-wheel rocker-type moving mechanism includes: 1-right rocker; 2-left rocker; 3-differential mechanism; 4-wheel; 5-turning drive mechanism; 6-travel drive mechanism; 7-transmission shaft; The differential mechanism and transmission shaft are located inside the lunar surface patrol, and the rocker arm, wheel train and driving mechanism are all located outside the lunar surface patrol. The housings of the rocker arm and the driving mechanism are all made of titanium alloy Material; the specific steps of the thermal control method of the six-wheel rocker-type mobile mechanism of the lunar surface patrol device are as follows:

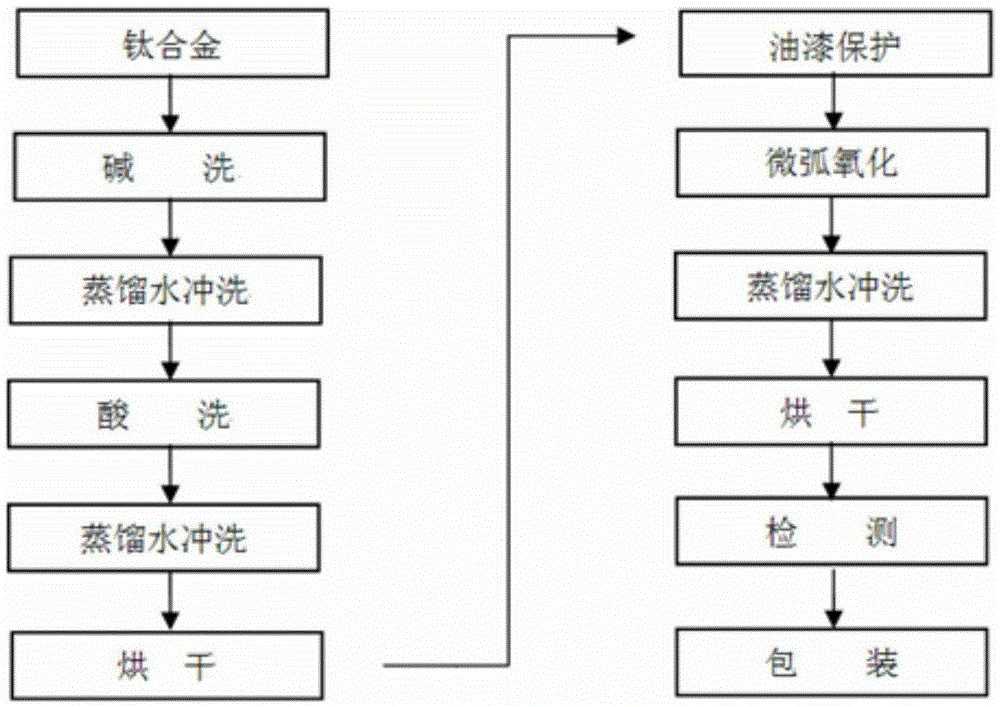

[0030] 1) For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com