BaSnO3 based multiphase electrolyte material and preparation method thereof

An electrolyte material, barium stannate technology, applied in the field of ceramic materials, can solve problems such as unsatisfactory electrical conductivity and difficult sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

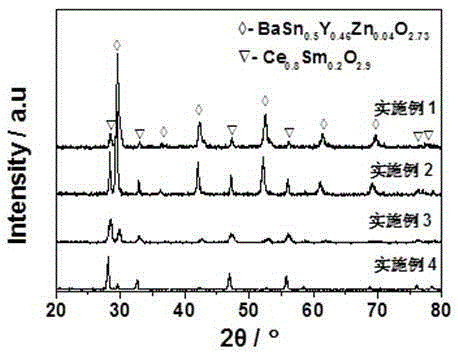

Embodiment 1

[0027] by 1gBaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Stoichiometric ratio weighed 0.6921gBaCO 3 , 0.2643gSnO 2 , 0.1821gY 2 o 3 And 0.0114gZnO (analytically pure), add 100mL ethanol, utilize ZrO 2 The balls are ground balls, milled in a planetary ball mill at 400rpm for 10h, dried at 80°C, and then calcined in a muffle furnace at 1000°C for 3h to obtain pure BaSn 0.5 Y 0.46 Zn 0.04 o 2.95 Powder. Press 9gCe 0.8 SM 0.2 o 2.9 Stoichiometric ratio weighed 18.1177gCe(NO 3 ) 3 ·6H 2 O and 4.6363gSm (NO 3 ) 3 ?6H 2 O, made into an aqueous solution with a metal cation molar concentration of 6mol / L, adding 10.0212g complexing agent citric acid (CA) [n(CA):n(metal cation)=1:1], adding NH 3 ﹒ h 2 O to adjust the pH of the mixed solution to 7. BaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Add the powder into the solution, ultrasonically disperse for 30min, then ball mill at 400rpm for 3h, take it out, heat and stir to 80°C to form a transparent gel, dry at 100°C for 10h, and calcinate ...

Embodiment 2

[0032] by 3gBaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Stoichiometric ratio weighs 2.0762gBaCO 3 , 0.7928gSnO 2 , 0.5464gY 2 o 3 And 0.0343gZnO (analytical pure), add 100mL ethanol, utilize ZrO 2 The balls are ground balls, milled in a planetary ball mill at 600 rpm for 8 hours, dried at 80°C, and then calcined in a muffle furnace at 1000°C for 3 hours to obtain pure BaSn 0.5 Y 0.46 Zn 0.04 o 2.95 Powder. Press 7gCe 0.8 SM 0.2 o 2.9 The stoichiometric ratio weighs 14.0915gCe(NO 3 ) 3 ·6H 2 O and 3.606gSm(NO 3 ) 3 ?6H 2 O (analytically pure), made into an aqueous solution with a cation molar concentration of 5mol / L, adding 15.5885g of citric acid complexing agent (CA) [n(CA):n(metal cation)=2:1], adding NH 3 ﹒ h 2 O to adjust the pH of the mixed solution to 7. BaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Add the powder into the solution, sonicate for 10min, then stir at 500rpm for 4h to mix the material evenly and break up the agglomeration of the powder, take it out and heat ...

Embodiment 3

[0035] By 5gBaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Stoichiometric ratio weighed 3.4604gBaCO 3 , 1.3214gSnO 2 , 0.9107gY 2 o 3 And 0.0571gZnO (analytically pure), add 100mL ethanol, utilize ZrO 2 The balls are ground balls, milled in a planetary ball mill at 500rpm for 7h, dried at 80°C, and then calcined in a muffle furnace at 900°C for 3h to obtain pure BaSn 0.5 Y 0.46 Zn 0.04 o 2.95 Powder. Press 5gCe 0.8 SM 0.2 o 2.9 The stoichiometric ratio weighs 10.0654gCe(NO 3 )3 ·6H 2 O and 2.5757gSm(NO 3 ) 3 ?6H 2 O (analytically pure), made into an aqueous solution with a cation molar concentration of 3mol / L, adding 16.7020g complexing agent citric acid (CA) [n(CA):n(metal cation)=3:1], adding NH 3 ﹒ h 2 O to adjust the pH of the mixed solution to 7. BaSn 0.5 Y 0.46 Zn 0.04 o 2.73 Add the powder into the solution, sonicate for 10min, then ball mill at 400rpm for 4h to mix the material evenly and break up the powder agglomeration, take it out and heat and stir to 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com