Wind-driven vehicle/vessel and upwind and crosswind running method thereof

A technology of vehicles and sails, which is applied in the field of wind-driven vehicles and their headwind and cross-wind driving, which can solve the problems of blank, wind-driven vehicles and ships unable to realize head-wind and cross-wind driving, and achieve the effect of environmental protection and saving fossil energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

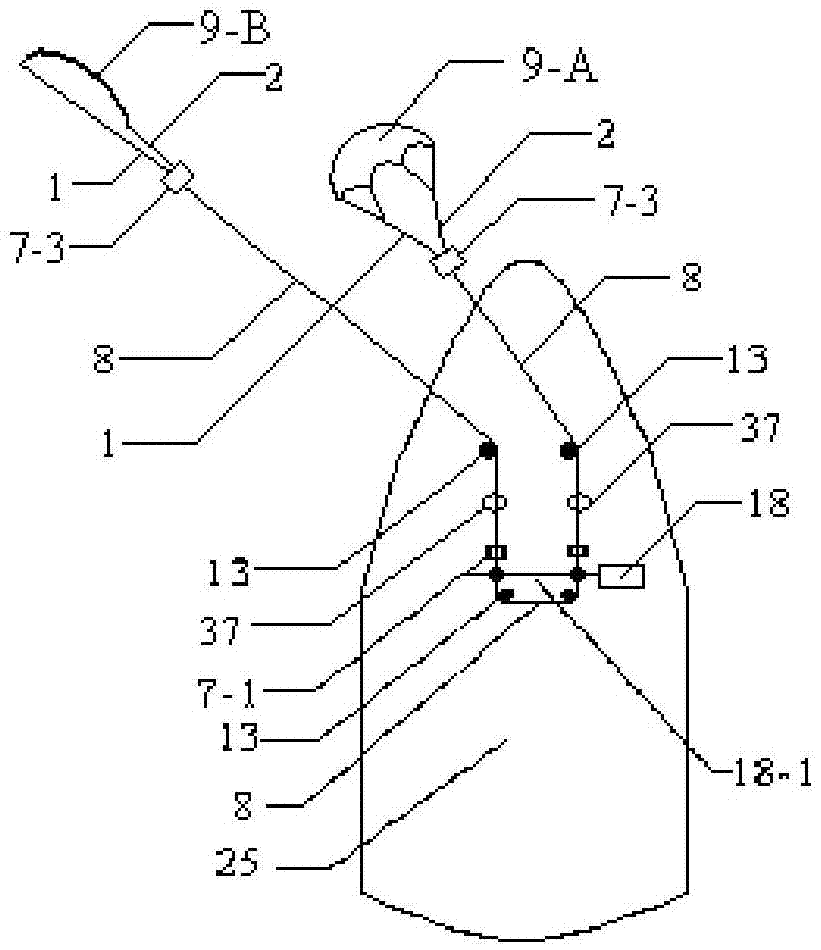

[0063] Embodiment one: if figure 1 On the deck of the ship, the kite generator described in embodiment one or embodiment two is provided with a kite type or a floating bag type kite generator (preferably a floating bag type), and the guide pulley 13 is also connected with the deck, and the kite body 9 Be connected with lightweight air bag 9-10, and the electric motor of ship or storage battery are made circuit connection with generator. Two cable retracting machines 37 are connected on the cable C8, and the supports of these two cable retracting machines are equipped with wheels, and the wheels are connected with the deck or the track on the deck (the purpose is to make the two cable retracting machines expand and contract with the cable C8). for linear reciprocating motion). In actual use, the two cable retractors must reclaim or lengthen the cable C8 at the same time. The purpose is to make the two kites 9 rise to the upper wind at the same time or fall to the lower wind at...

Embodiment 2

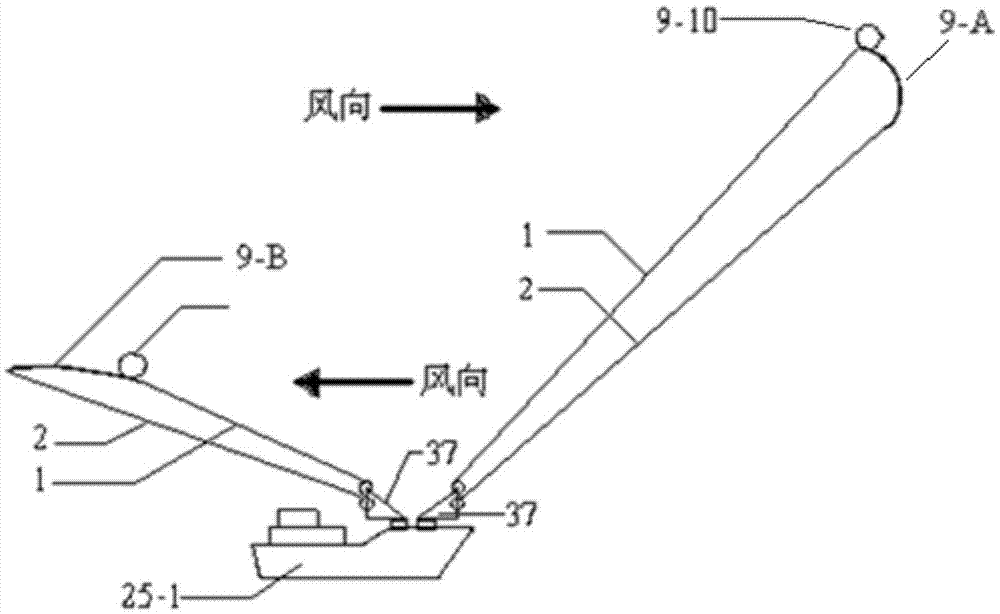

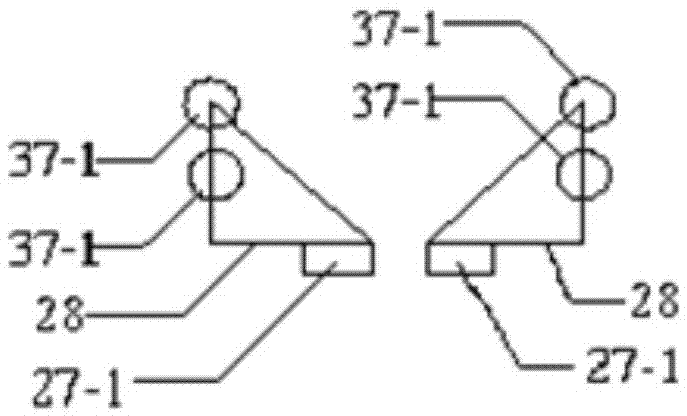

[0064] Embodiment two: if figure 2 , image 3 , the two zither bodies are respectively in the upper and lower wind layers and are opposite to each other, the cable retractor 37 is connected with the outer ring (or inner ring) of the bearing 27-1, and the inner ring (or outer ring) of the bearing 27-1 is connected with the ship The deck is connected, and the connection point should be at the front of the ship, which ensures that when another kite is towed (that is, when the direction of towing is changed), the U-turn problem of the kite body is guaranteed. In actual use, when pulling the hull forward, one kite must be in a fully charged state and the other kite must be in a fully discharged state; when the ship needs to park, the two kites should be in a fully charged state or simultaneously fully de-energized state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com