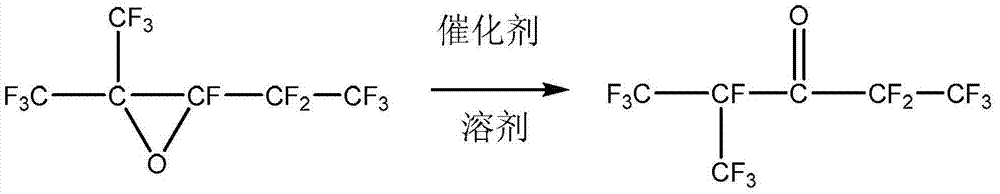

Preparation method of C6-fluoroketone

A catalyst and epoxy technology, applied in the preparation of heterocyclic compounds, organic chemistry, etc., can solve the problems of low formula conversion rate, easy deactivation, unstable reaction yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

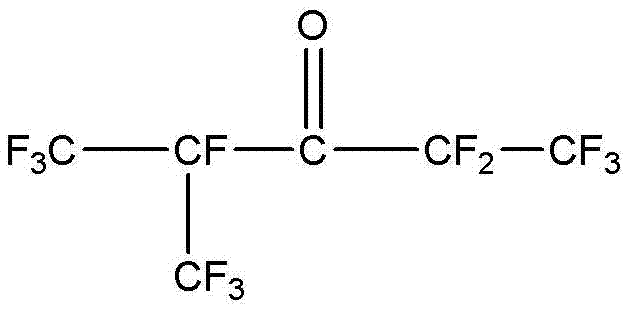

Image

Examples

Embodiment 1

[0028] Add 400ml of acetonitrile and 4g of metformin into a 1000mL closed reaction kettle equipped with mechanical stirring, control the reaction temperature at 45°C, add 300g of perfluoro-2,3-epoxy-2-methylpentane, and react for a total of 4 hours. After the reaction, the molar yield of perfluorohexanone was 96.5% through separation and analysis.

Embodiment 2

[0030] Add 400ml of acetonitrile and 5g of conjugated tetramethylguanidine to a 1000mL closed reaction kettle equipped with mechanical stirring, control the reaction temperature at 40°C, add 300g of perfluoro-2,3-epoxy-2-methylpentane, The total reaction time was 3 hours. After the reaction, the molar yield of perfluorohexanone was 95.5% through separation and analysis.

Embodiment 3

[0032] Add 400ml of acetonitrile and 5g of bicyclic guanidine into a 1000mL closed reaction kettle equipped with mechanical stirring, control the reaction temperature at 50°C, add 300g of perfluoro-2,3-epoxy-2-methylpentane, and react for a total of 3 hours After the reaction, the molar yield of perfluorohexanone was 94.8% through separation and analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com