Low-cost colloidal silica anti-reflection coating liquid and preparation and application thereof

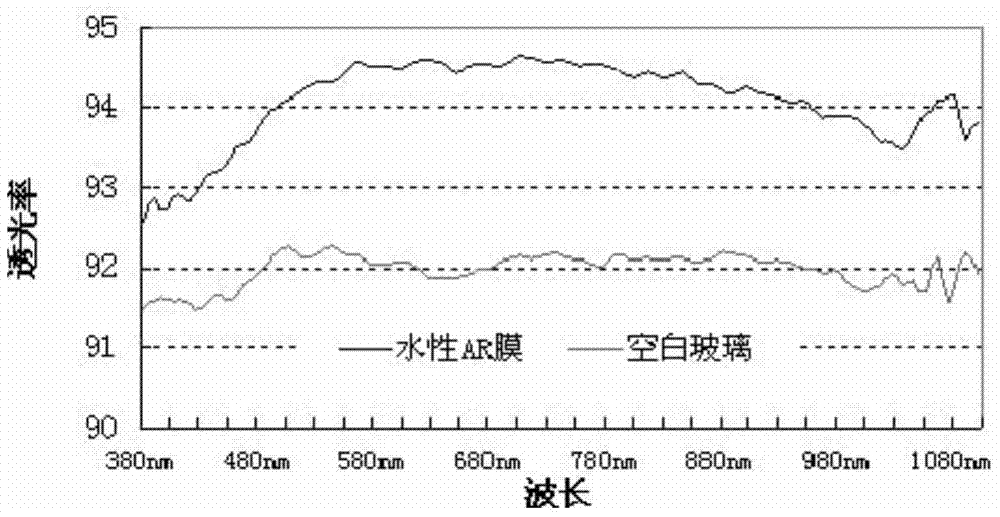

A technology of silica sol and coating solution, applied in the direction of coating, etc., can solve the problems of poor stability, poor film-forming performance, and low anti-reflection film anti-reflection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

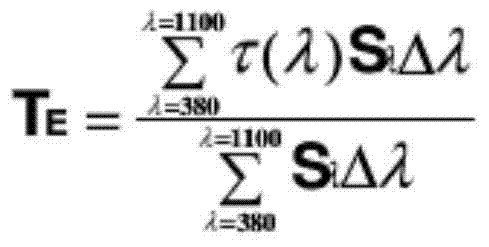

AI Technical Summary

Problems solved by technology

Method used

Image

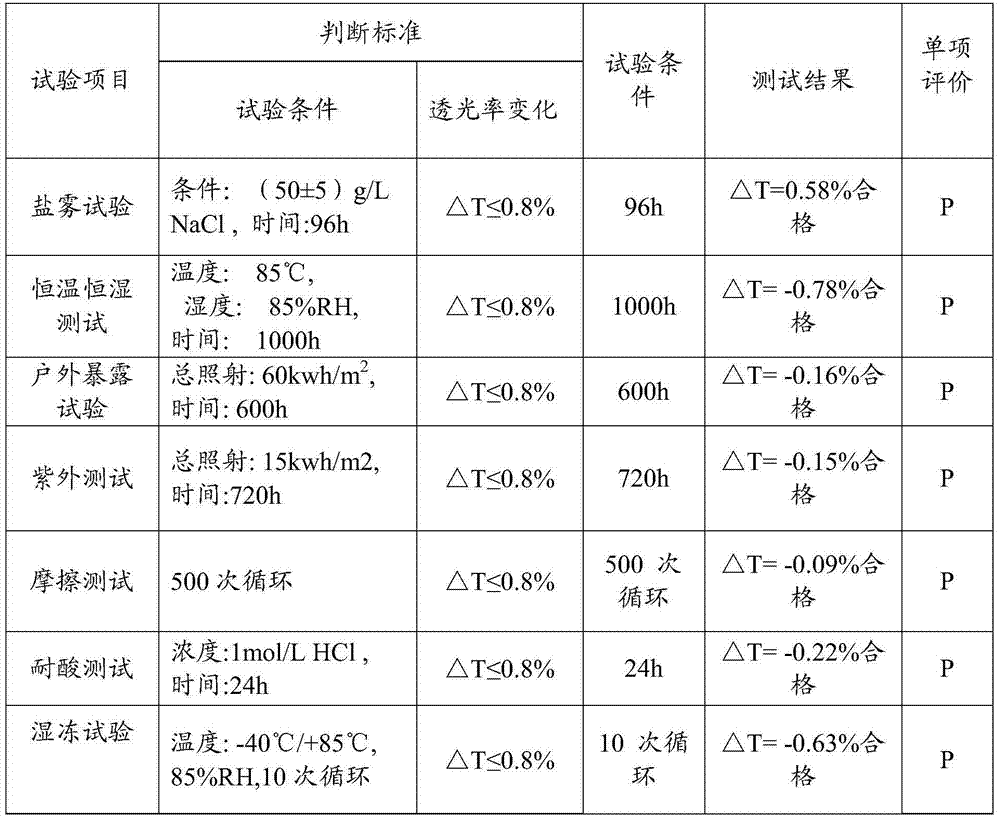

Examples

Embodiment 1

[0050] The steps of preparing 1# coating solution are as follows :

[0051] (1) add deionized water in the reactor that 150g organic solvent type silica sol (organic solvent is methyl alcohol, silica sol mass content is 20%) is housed, and adjust sol pH to 2 with the dilute phosphoric acid of mass percent concentration 20% , wherein, the mass ratio of deionized water to the organic solvent silica sol is 2%, the mass ratio of dilute phosphoric acid to the organic solvent silica sol is 0.1%, and the mixed solution A is obtained by stirring evenly;

[0052] (2) Drop the silane coupling agent methyltrimethoxysilane into the mixed solution A, stir at room temperature for 4 hours to obtain the modified silica sol B, wherein the amount of the silane coupling agent added is 1% of the mass of the mixed solution A .

[0053] (3) Add methanol and stir evenly to prepare a coating solution with a solid content of 5%. The coating solution is numbered 1#.

[0054] Wherein, carry out soli...

Embodiment 2

[0076] The steps of preparing 2# coating solution are as follows:

[0077] (1) add deionized water in the reactor that 150g organic solvent-type silica sol (organic solvent is ethanol, silica sol mass content is 40%) is housed, and adjust sol pH to 3 with the dilute phosphoric acid of mass percent concentration 20% , wherein, the mass ratio of deionized water to the organic solvent silica sol is 10%, the mass ratio of dilute phosphoric acid to the organic solvent silica sol is 2%, and the mixed solution A is obtained by stirring evenly;

[0078] (2) Drop the silane coupling agent methyltrimethoxysilane into the mixed solution A, and stir at room temperature for 4 hours to obtain the modified silica sol B, wherein the addition amount of the silane coupling agent is 10% of the mass of the mixed solution A .

[0079] (3) Slowly add the leveling agent BYK333 and the wetting agent BNK-NSF067 as auxiliary agents into the modified silica sol B according to the mass 1:2, wherein th...

Embodiment 3

[0093] The steps of preparing 3# coating solution are as follows:

[0094] (1) Add deionized water to a reactor equipped with 150g commercially available organic solvent-type silica sol (organic solvent is propanol, and the mass content of silica sol is 30%), and adjust with dilute phosphoric acid of mass percent concentration 20%. The sol has a pH of 5, wherein the mass ratio of deionized water to the organic solvent silica sol is 7%, and the mass ratio of dilute phosphoric acid to the organic solvent silica sol is 1.5%, and the mixed solution A is obtained by stirring evenly;

[0095] (2) Drop the silane coupling agent methyltrimethoxysilane into the mixed solution A, and stir at room temperature for 4 hours to obtain the modified silica sol B, wherein the addition amount of the silane coupling agent is 7% of the mass of the mixed solution A .

[0096] (3) Slowly add leveling agent TEGO410, wetting agent EW332 and volatilization control agent N,N-dimethylformamide as auxili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com