Camellia oil cold processed soap

A technology of cold soap and camellia oil, applied in the direction of alkali soap/ammonium soap composition, soap detergent composition, chemical instruments and methods, etc., can solve the problem of destroying the pH value, not being suitable for large-scale use, and the price of surfactants Expensive and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0202] The preparation method of the tea seed powder: the natural plant saponins are directly and fully crushed.

[0203] The preparation method of matcha: the fresh tender tea leaves are steamed green→rough kneading→kneading→medium kneading→fine kneading→drying. Among them, the structure of the dryer has its special requirements. It is 10-15 meters long, 1.5-2 meters wide, and 2.5-4.5 meters high. 90-100 degrees Celsius; the upper layer is dry again, the central temperature is 90-110 degrees Celsius, and the outlet temperature is 82-100 degrees Celsius. Tencha dried by a dryer has a water content of about 9% in the leaves (very easy to crush) and 51% to 54% in the stem (still tough and not easy to break). The stems and leaves can be easily separated by the stem and leaf separator Separate and sieve the crushed leaves, and then dry them with hot air at about 65-75 degrees Celsius for 12 minutes, which is the crude ground tea; the crude ground tea is removed by air separation ...

Embodiment

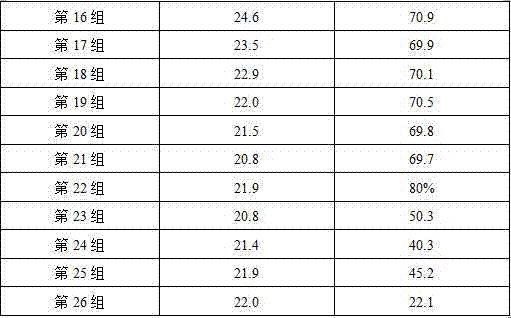

[0208] Table 1

[0209]

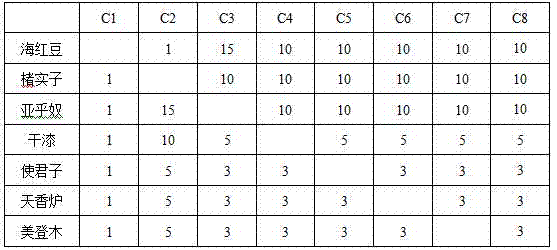

[0210] Table 2

[0211]

[0212] table 3

[0213]

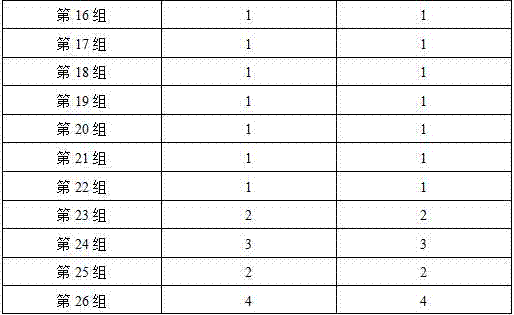

[0214] Table 4

[0215]

[0216]

[0217] Evaluation method

[0218] 1. Whitening function test.

[0219] 125 volunteers were selected and divided into 25 groups with 5 volunteers as a group. Group 1 used Example 1, Group 2 used Example 2, Group 3 used Example 3, Group 4 used Example 4, Group 5 used Example 5, Group 6 used Example 6, Group 7 Group 7 used Example 8, Group 8 used Example 8, Group 9 used Example 9, Group 10 used Example 10, Group 11 used Example 11, Group 12 used Example 12, and Group 13 used Example 10 Example 13, Group 14 used Example 14, Group 15 used Example 15, Group 16 used Example 16, Group 17 used Example 17, Group 18 used Example 18, Group 19 used Example 19. Group 20 uses Example 20, Group 21 uses Example 21, Group 22 uses Example 22, Group 23 uses Example 23, Group 24 uses Example 24, Group 25 uses Example 25, The 26th group used Example 26, and all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com