Uniform discharge low-temperature plasma fabric processing device and method under intelligent atmospheric pressure

A low-temperature plasma and fabric treatment technology, applied in physical treatment, fiber treatment, ultrasonic/sonic fiber treatment, etc., can solve the problems of inaccurate control of the discharge energy, uneven plasma density, and failure to reach the tension. Achieve the effect of improving production efficiency and product quality, high discharge density and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

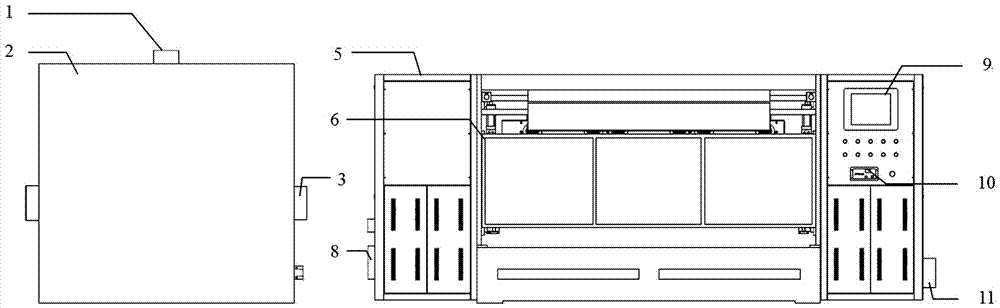

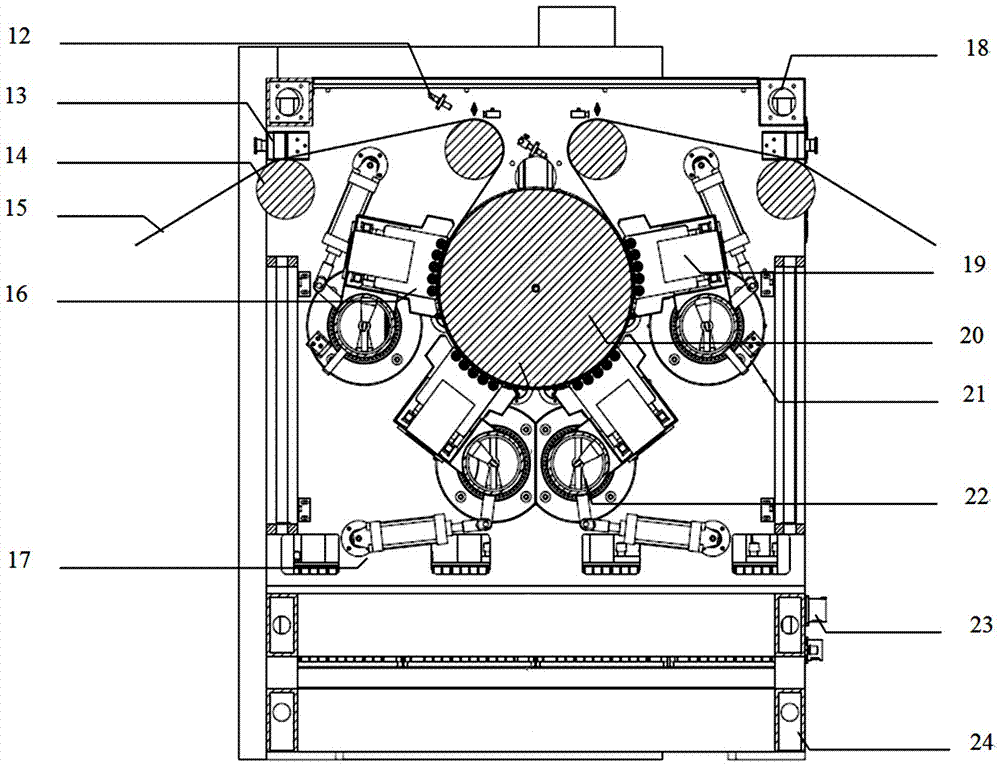

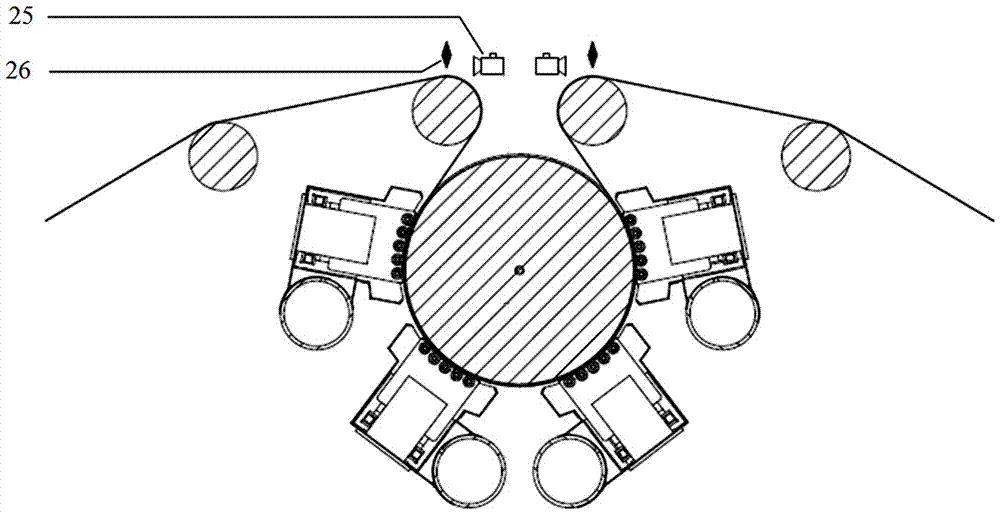

[0025] Such as Figure 1 to Figure 3 The shown intelligent uniform discharge low-temperature plasma fabric treatment equipment under atmospheric pressure includes a main body chassis, a sound insulation cooling device 2, and power cabinets 5 and control cabinets respectively located on the left and right sides of the main chassis. The control cabinet is provided with a touch screen 9, a tension controller 10, a power input terminal 11 and the like.

[0026] A base 24 and an equipment data connection interface 24 are provided below the main chassis, and an active discharge roller 20, four corundum electrode groups 16 symmetrically arranged around the active discharge roller 20, several fabric guide rollers 14, emergency stop Switch 13, balance pull bar 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com