Protection method and device for drilling tool mark

A protection device and imprinting technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of drilling tool imprint wear, drilling tool usage accidents and waste, etc., to prevent mud erosion, reduce drilling costs, and ensure accurate drilling sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

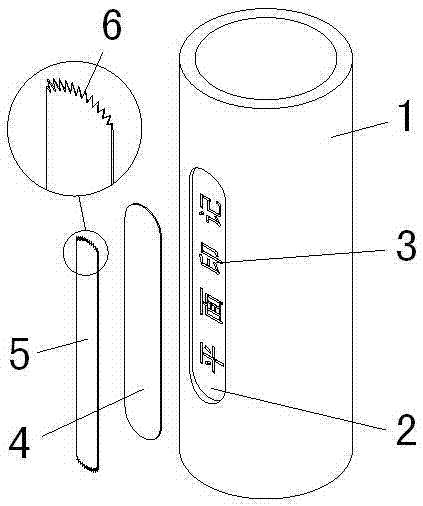

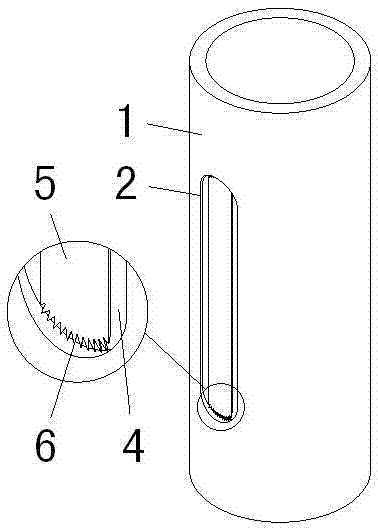

Image

Examples

Embodiment

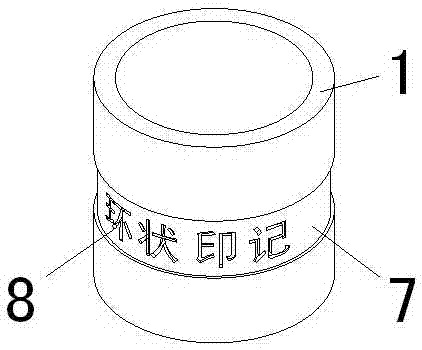

[0024] This example is an improvement on existing technologies, such as image 3 As shown, the prior art is an annular groove with a width of 20 mm and a depth of 1 mm formed by direct turning on the outer surface of the workpiece. After the processing is completed, the part information is recorded on the 20mm wide surface of the annular imprint groove. After the imprint of the prior art is used for a period of time, it often occurs that the imprint is blurred and unrecognizable due to wear and tear, and finally the use record cannot be completed. Without the support of accurate records, it is very easy for drilling tools to be overdue or scrapped early, resulting in unnecessary accidents and waste. In addition, the surface of the existing ring-shaped marking groove 7 is arc-shaped, so the existing marking is a ring-shaped marking 8, and most of the marking printing devices need to work on a plane to obtain excellent printing effects. However, the imprint printed on the ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com