Micro-miniature air compressor lifting handle integrated with air filtering and air intake silencing functions

An air compressor and air filtration technology, which is applied in the field of compressors, can solve the problems of loose overall layout of compressors, poor amenity, increased manufacturing and assembly processes and workload, etc., so as to improve appearance and layout, reduce manufacturing and Assembly cost, effect of reducing packaging and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

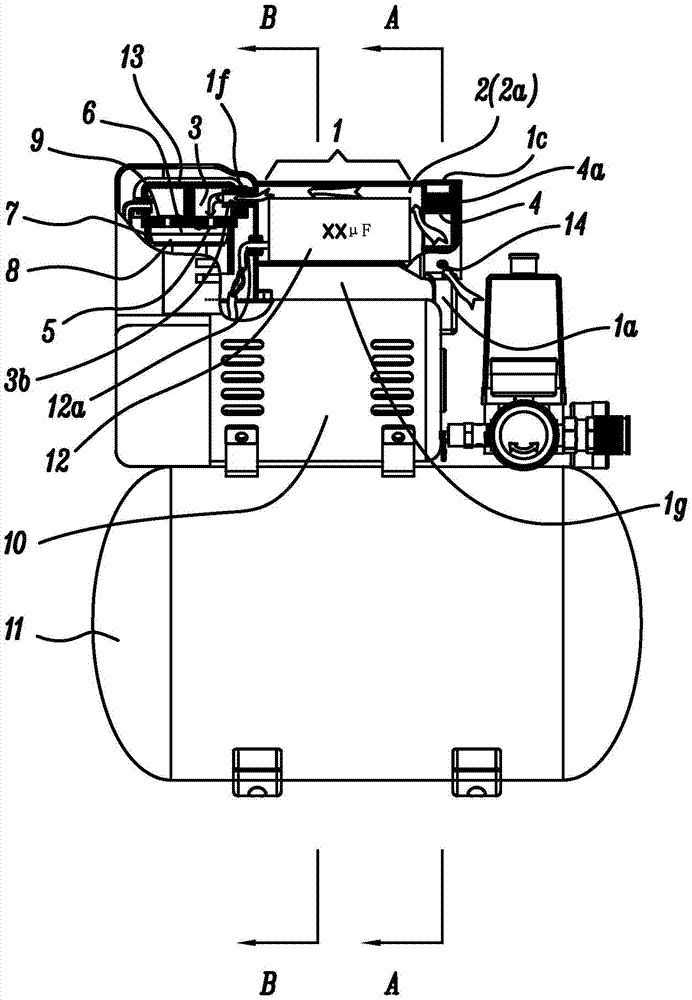

[0036] The present invention will be further described below with specific embodiment, see figure 1 — Figure 18 :

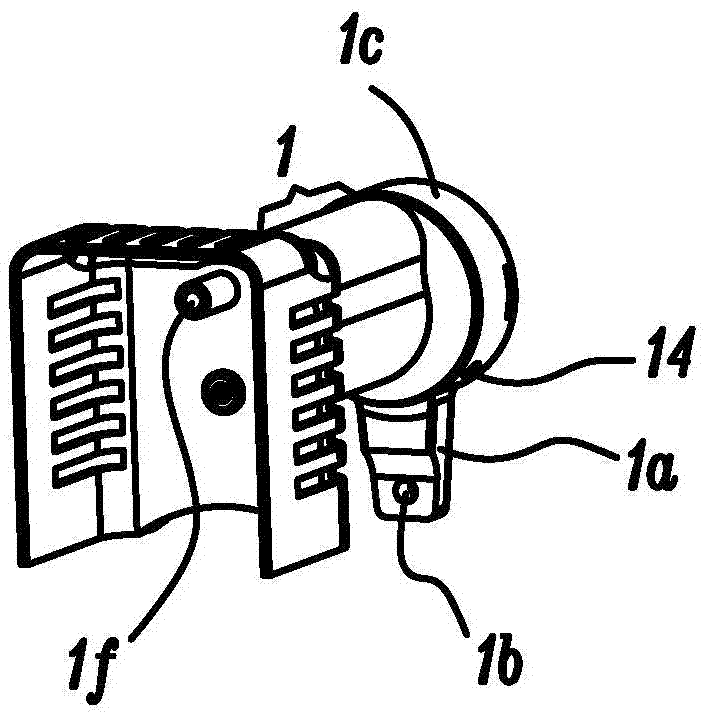

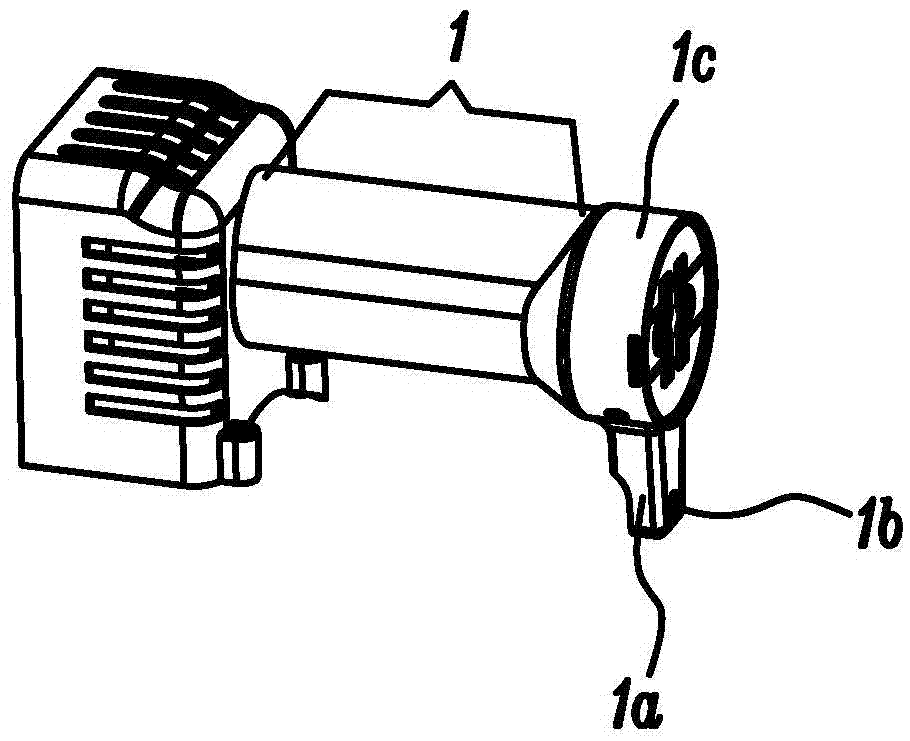

[0037] A handle of a miniature air compressor integrated with air filtering and intake muffler functions, the handle includes a handle body 1 that can be grasped or grasped, and is characterized in that the handle has a hollow inner Chamber 2 structure (see image 3 , Figure 5 , Figure 6 , Figure 9 , Figure 11 , Figure 12 , Figure 14 to Figure 16 ), the hollow inner chamber 2 constitutes the air inlet of the compressor and becomes the second intake muffler cavity 2a of the compressor, and the second intake muffler cavity 2a communicates with the first intake muffler cavity 3 provided on the compressor , in addition, a filter element 4 for filtering air is arranged in the hollow inner cavity 2 (see image 3 , Figure 5 , Figure 11 , Figure 14 and Figure 15), at this time, the outside air can pass through the filter element 4 and be filtered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com