3D imaging grating assembly and 3D display device

A display device and 3D technology, applied in the field of 3D display, can solve the problems of large volume, large thickness, and difficulty in full lamination, etc., and achieve the effects of simplifying the installation process, simple processing process, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

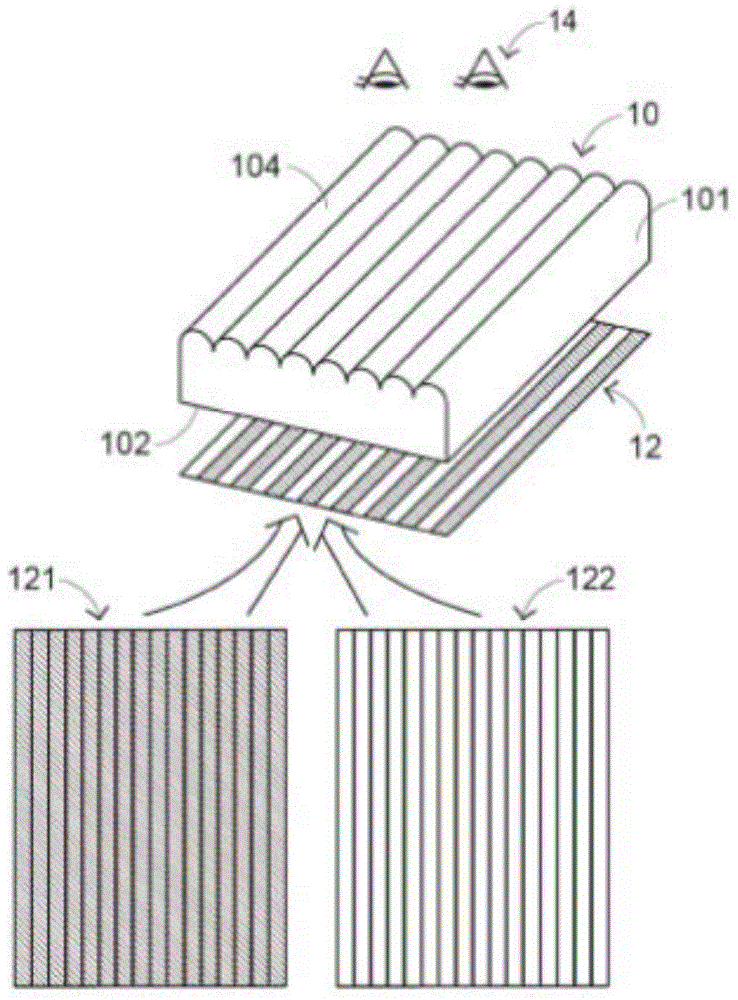

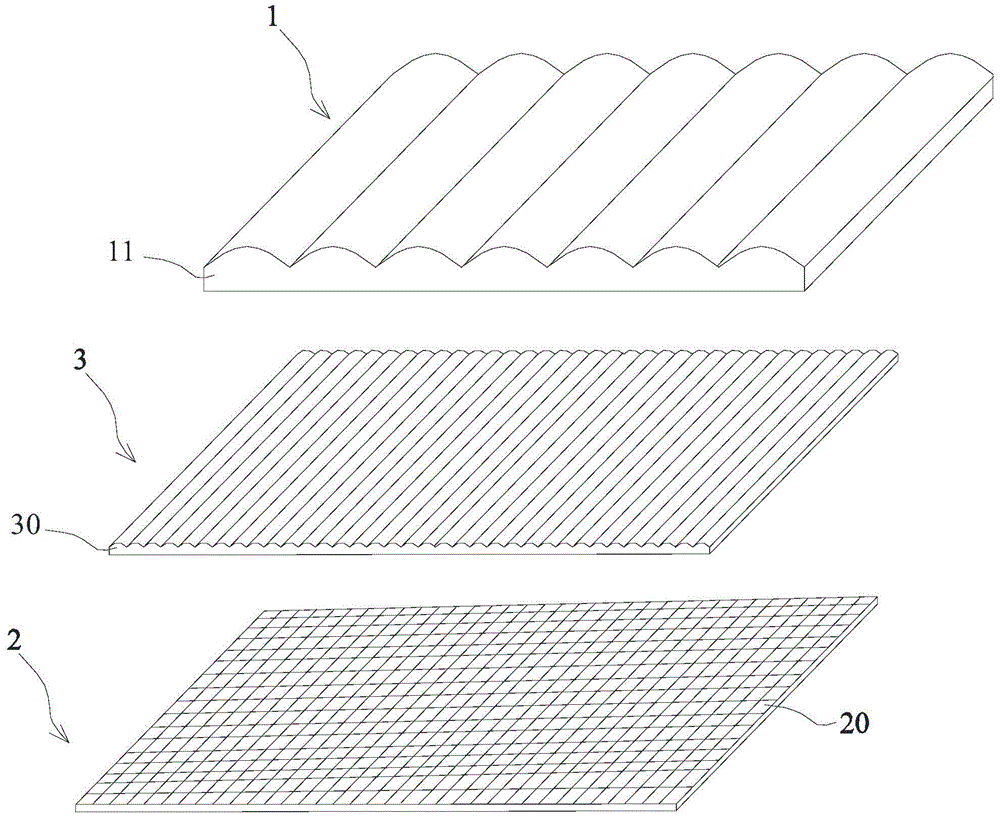

[0040] This example will describe in detail the 3D imaging grating assembly disclosed in the present invention, such as Figure 2a , Figure 2b As shown, it discloses a three-dimensional exploded schematic diagram of a 3D display device including a 3D imaging grating assembly and a display panel 2; the 3D imaging grating assembly includes a spectroscopic lens array grating 1 and a collimating lens array grating 3;

[0041] The collimating lens array grating 3 is provided with several collimating lenses 30 distributed in an array;

[0042] The beam-splitting lens array grating 1 includes several beam-splitting lenses 11 arranged in an array;

[0043] Among them, such as image 3 As shown, the width D of the collimating lens is 1 / N of the width of a pixel or sub-pixel (the following will be illustrated in units of pixels) of the display panel 2, and the width H of the dichroic lens 11 is 1 / N of the width of the display panel 2. 2 M times the width of the viewpoint group, wher...

Embodiment 2

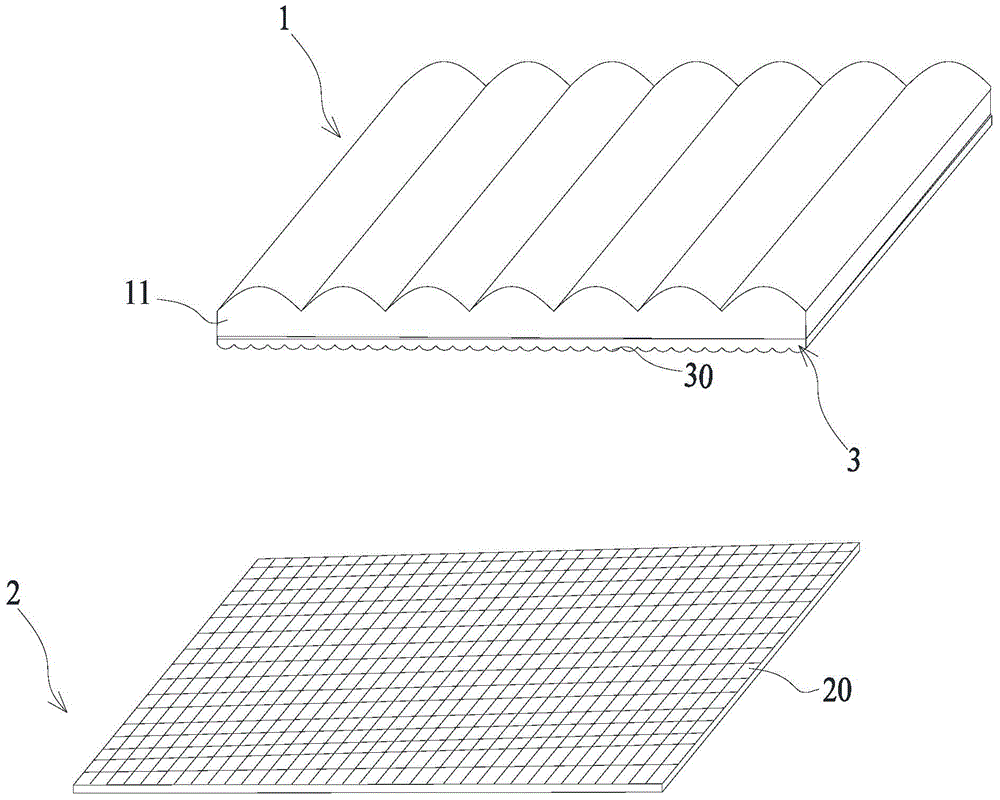

[0066] In this example, a 3D display device will be described with reference to the accompanying drawings. like image 3 As shown, including a display panel 2 and a 3D imaging grating assembly;

[0067] The 3D imaging grating assembly is installed in front of the display panel 2 .

[0068] When installing, such as Figure 6-Figure 8 As shown, the 3D imaging grating assembly is installed in front of the display panel 2 by using a transparent medium 4 , that is, one side of the collimator lens array grating 3 is pasted on the display panel 2 . Specifically, the thickness of the transparent medium 4 is related to the width of the pixels on the display panel 2 and the divergence angle θ.

[0069] like Image 6 , Figure 7 As shown, each pixel or sub-pixel on the display panel 2 is a light source, such as an LED light 21 . In the figure, w1 is the thickness of the thinnest part of the collimating lens 30 , and w2 is the distance between the collimating lens 30 and the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com