Connector and contactor assembly

A connector and contactor technology, applied in relays, electrical components, electromagnetic relays, etc., can solve the diversification limitation of contactor or relay control circuit, high contactor cost and product maintenance cost, and increase in contactor or relay cost, etc. problems, to achieve the effect of expanding physical limitations, avoiding electromagnetic interference, and releasing limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Reference will now be made to specific embodiments, examples of which are illustrated in the accompanying drawings. In the detailed description of particular embodiments, directional terms such as "top", "bottom", "above", "below", "left", "right", etc. are used with reference to the directions described in the drawings. Since components of embodiments of the present invention may be arranged in many different orientations, directional terms are used for purposes of illustration and are by no means limiting. Wherever possible, the same or similar numbers and symbols will be used throughout the drawings to refer to the same or like parts.

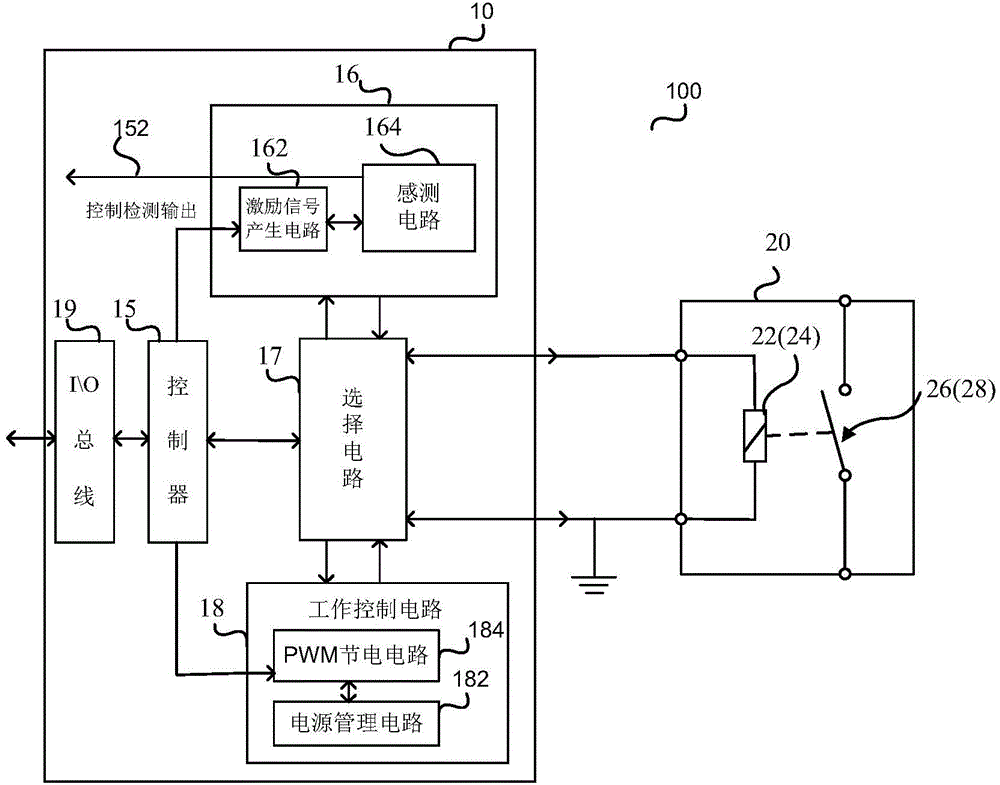

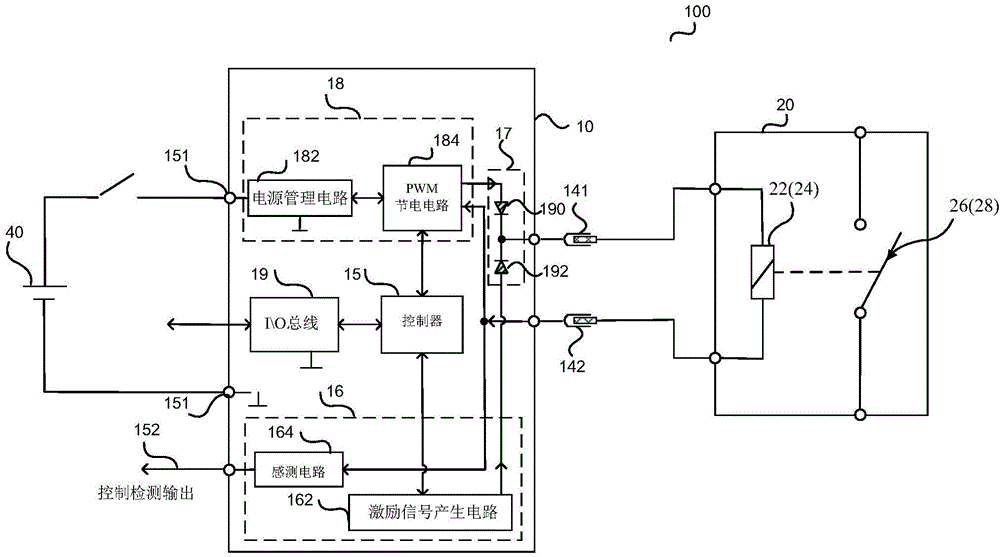

[0040] figure 1 It is a schematic diagram of the circuit structure of the contactor 20 in the first embodiment of the present invention.

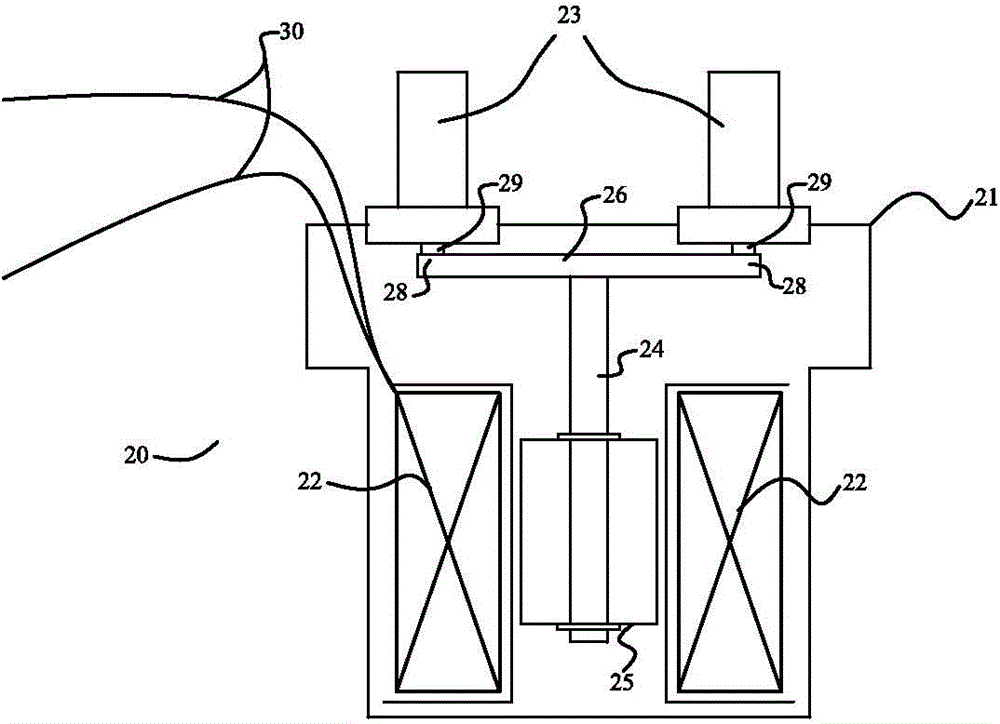

[0041] Such as figure 1 As shown, the contactor (or relay) 20 includes a control circuit 10 connected to the contactor 20 . The contactor 20 has a contactor housing 21 (see Figure 3A-3B ), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com