Coarse-grain ultrahard abrasive material orderly arraying device and arraying method

A superhard abrasive and coarse-grained technology, which is applied in the field of abrasive tool manufacturing, can solve the problems of uniform density and low efficiency of molding materials, and achieve the effect of efficient, rapid and orderly arrangement of multiple layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

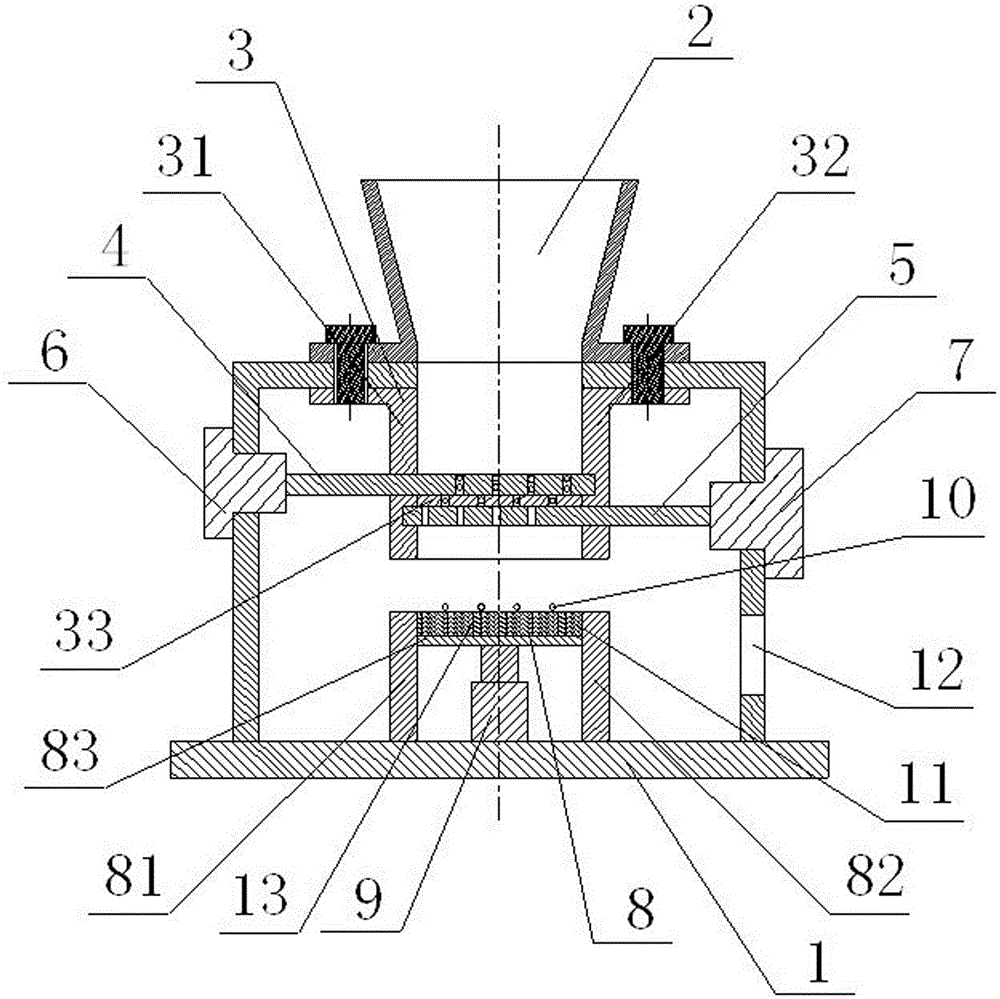

[0034] Such as figure 1As shown, a device for orderly arranging coarse-grained superabrasives according to the present invention includes a housing 1, the housing 1 is composed of a base and a housing fixedly connected to the base, and the outer side of the upper end of the housing 1 is fixedly connected There is a storage bin 2, and a template 3 is fixedly connected to the inner side of the upper end of the shell of the shell 1, and the template 3 communicates with the discharge port at the bottom of the storage bin 2, and the template 3 includes a vertically arranged first splint 31, The second clamping plate 32 vertically arranged, the connecting plate 33 arranged horizontally, the connecting plate 33 is located between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com