A constant-temperature large-scale preparing method of belt-shaped black phosphorus

A large-scale preparation and strip-shaped technology, which is applied in the field of constant temperature and large-scale preparation of strip-shaped black phosphorus, can solve the problems of inability to achieve large-scale mass production, the limitation of black phosphorus production, and the increase of preparation cost, and achieves improved productivity and surface area. Smooth, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Tin, high-purity red phosphorus, and iodine are mixed according to the ratio (mass ratio) of tin: red phosphorus: iodine=0.6:20:0.1, and then put into a quartz tube and directly seal the tube; then put the sealed quartz tube into a horse boiling furnace , the number of quartz tubes to be put in depends on the volume of the horse boiling furnace; set the reaction time, then raise the temperature to 650°C, keep it for 2h, then cool it down to 300°C, keep it for 2h, and finally cool down slowly to room temperature (10h). The resulting strip-shaped black phosphorus is evenly distributed in the quartz tube, such as figure 1 shown.

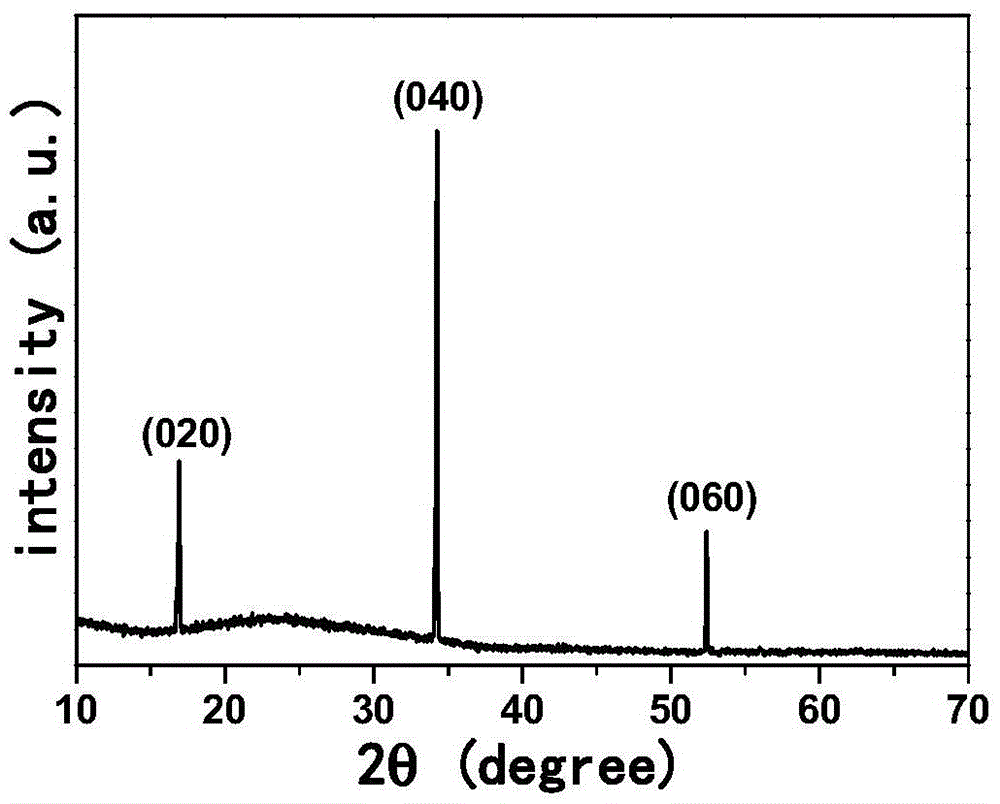

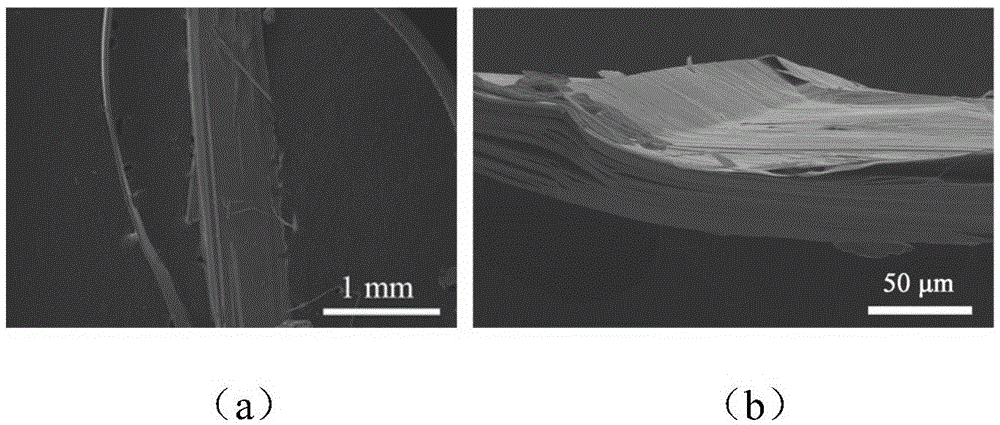

[0016] The resulting product is a black ribbon block, figure 2 Its XRD figure, its SEM such as image 3 As shown, it can be seen that the obtained product is black phosphorus. And it is measured that the mass of the obtained black phosphorus is about 97% of the mass of the red phosphorus in the raw material.

[0017] Select the resulting str...

Embodiment 2

[0018] Tin, high-purity red phosphorus, and iodine are mixed according to the ratio of tin: red phosphorus: iodine=1:18:0.4, then put into the quartz tube and directly seal the tube; then put the sealed quartz tube into the horse boiling furnace, the number of quartz tubes Depends on the volume of the horse boiler; set the reaction time, then raise the temperature to 750°C, keep it warm for 5h, then cool down to 400°C, keep warm for 5h, and finally cool down slowly to room temperature (15h). The obtained long black phosphorus is evenly distributed in the quartz tube.

Embodiment 3

[0020] Tin, high-purity red phosphorus, and iodine are mixed according to the ratio of tin: red phosphorus: iodine=3:40:0.5, then put into the quartz tube and directly seal the tube; then put the sealed quartz tube into the horse boiling furnace, the number of quartz tubes Depends on the volume of the horse boiler; set the reaction time, then raise the temperature to 500°C, keep it warm for 10h, then cool down to 200°C, keep it warm for 8h, and finally cool down slowly to room temperature (20h). The obtained long black phosphorus is evenly distributed in the quartz tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com