Method for smelting high-nickel molten iron through low-poor-grade nickel laterite ore

A technology of laterite nickel ore and grade, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of incompetence, high power consumption, heavy burden on ball mills, etc., and achieve the effects of reducing the degree of ring formation, reducing costs and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

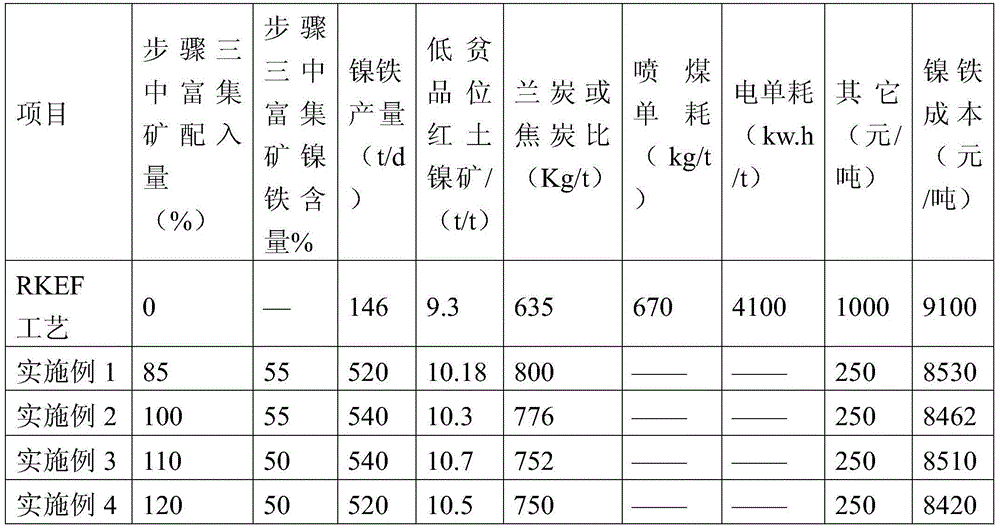

Examples

Embodiment 1

[0095] (1) Roasting reduction: take 100 parts by weight of low-grade lateritic nickel ore, dry until the water content is 16% to 19%, and crush until the particles with a particle size of ≤3mm account for more than 80% of the total number of particles; then add limestone 2 Parts by weight, 15 parts by weight of reduced carbon; roasting reduction treatment is carried out in a rotary kiln, wherein the temperature of the preheating zone is 500°C, the temperature of the decomposition transition zone is 1000°C, the temperature of the high temperature reduction zone is 1350°C, and the condensation zone (kiln head) The discharge temperature is 1150°C, and iron slag ore is obtained.

[0096] (2) Magnetic separation: the above-mentioned iron slag ore is carried out magnetic separation enrichment to obtain selected enrichment ore. The specific magnetic separation enrichment process is as follows:

[0097] Firstly, the self-unloading permanent magnet iron remover is used to carry out the...

Embodiment 2

[0117] (1) Roasting and reduction: take 100 parts by weight of low-grade laterite nickel ore, dry it until the water content is 16% to 19%, and crush it until the particles with a particle size of ≤3mm account for more than 80% of the total number of particles; add limestone 3 Parts by weight, 14 parts by weight of reduced carbon; roasting reduction treatment is carried out in a rotary kiln, wherein the temperature of the preheating zone is 400°C, the temperature of the decomposition transition zone is 850°C, the temperature of the high temperature reduction zone is 1300°C, and the condensation zone (kiln head) The discharge temperature is 1100°C, and iron slag ore is obtained;

[0118] (2) Magnetic separation: the above-mentioned iron slag ore is carried out magnetic separation enrichment to obtain selected enrichment ore. The specific magnetic separation enrichment process is as follows:

[0119] Firstly, the self-unloading permanent magnet iron remover is used to carry out ...

Embodiment 3

[0139] (1) Roasting reduction: take 100 parts by weight of low-grade lateritic nickel ore, dry until the water content is 16% to 19%, and crush until the particles with a particle size of ≤3mm account for more than 80% of the total number of particles; then add limestone 2 Parts by weight, reduced carbon 13 parts by weight; Carry out roasting and reduction treatment in the rotary kiln, wherein, the temperature of the preheating zone is 400°C, the temperature of the decomposition transition zone is 800°C, the temperature of the high temperature reduction zone is 1250°C, and the condensation zone (kiln head) The discharge temperature is 1050°C, and iron slag ore is obtained.

[0140] (2) Magnetic separation: the above-mentioned iron slag ore is carried out magnetic separation enrichment to obtain selected enrichment ore. The specific magnetic separation enrichment process is as follows:

[0141] Firstly, the self-unloading permanent magnet iron remover is used to carry out the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com