Energy conservation and emission reduction system with double back-pressure condensers in thermal power station

A thermal power plant, energy-saving and emission-reduction technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of low heat transfer efficiency and volume reduction of condensers, and achieve low ultimate pressure and suction pressure difference The effect of increasing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

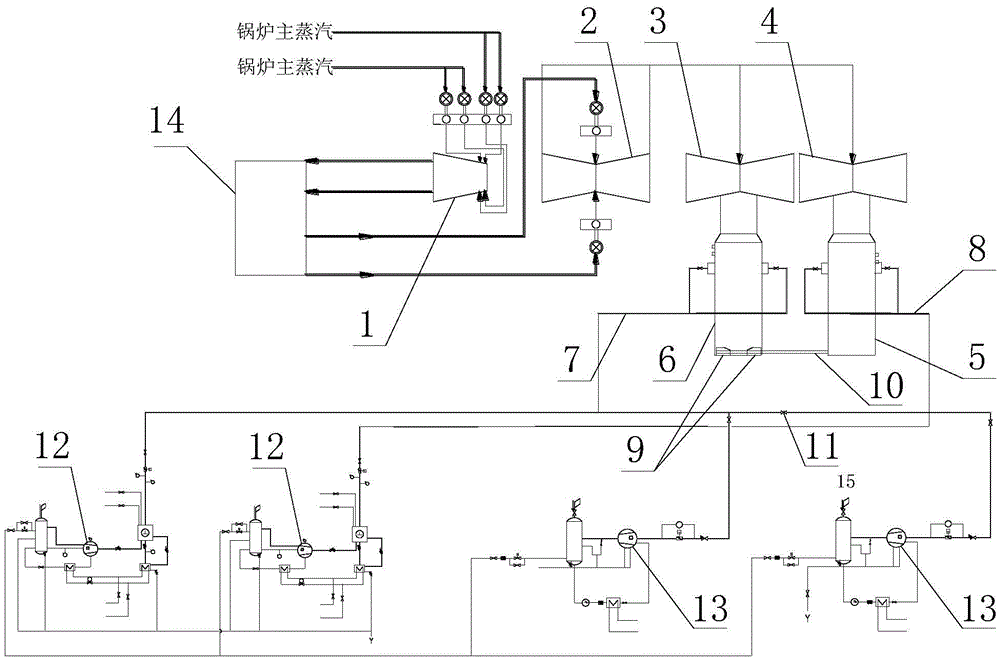

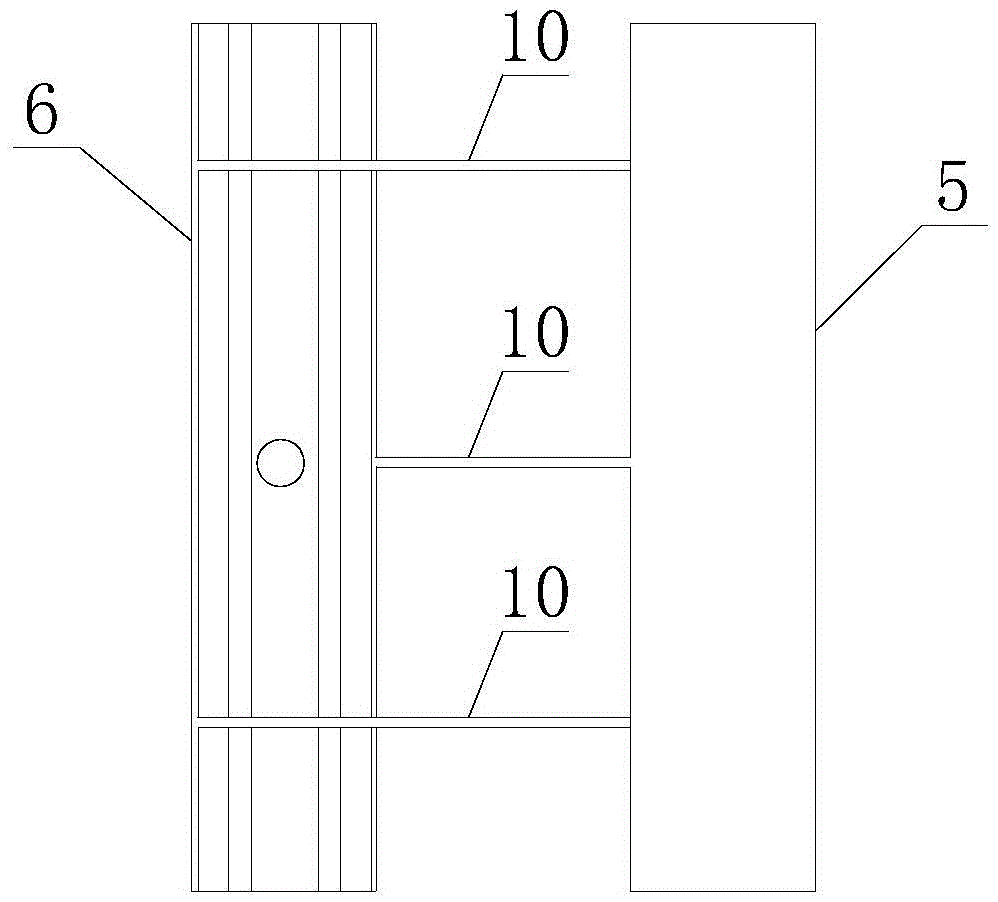

[0020] Embodiments of the present invention: as figure 1 and figure 2 As shown, an energy-saving and emission-reduction system with dual back pressure condensers in a thermal power plant includes a steam turbine high-pressure cylinder 1, a medium-pressure cylinder 2, A low-pressure cylinder 3, B low-pressure cylinder 4, a low-pressure condenser 5 and a high-pressure condenser 6. The steam turbine high-pressure cylinder 1 is connected to the medium-pressure cylinder 2, A low-pressure cylinder 3 and B low-pressure cylinder 4 are connected to the medium-pressure cylinder 2, A low-pressure cylinder 3 is connected to the high-pressure condenser 6, B low-pressure cylinder 4 is connected to the low-pressure condenser The condenser 5 is connected, the water side of the bottom of the low-pressure condenser 5 and the high-pressure condenser 6 are connected, and also includes a high-power water ring vacuum pump 12 and a three-stage Roots variable frequency pump group 13, a high-power wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com