Process for improving negative photoresist storage stability of cyclized isoprene system

A technology for cyclization of isoprene and storage stability, applied in the direction of photosensitive materials for optomechanical equipment, etc., can solve the problem of loss of protection of photoresist, and achieve low production cost, mild operating conditions, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

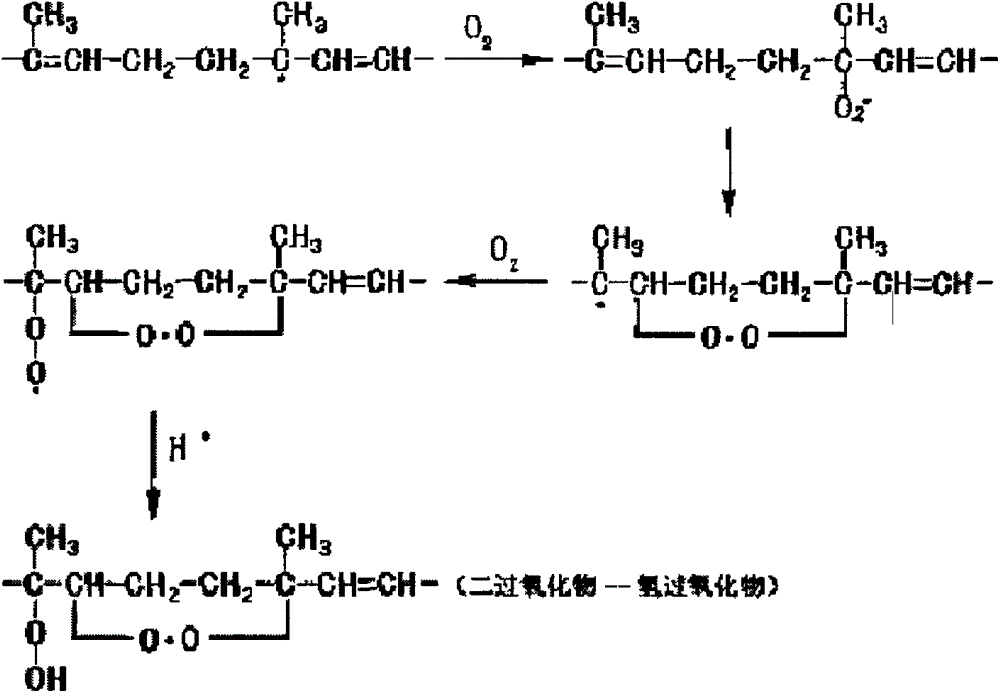

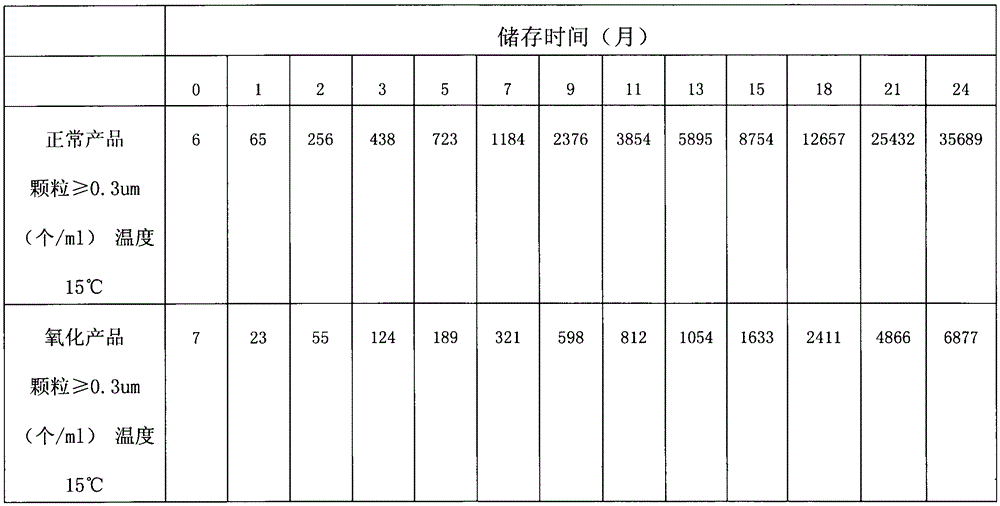

Method used

Image

Examples

Embodiment Construction

[0018] 1. First, add polyisoprene into xylene, fully dissolve, add catalyst butyllithium, raise the temperature to 50°C, keep it for 2 hours, check the molecular weight with gel chromatography, and add a terminator when it reaches the specified value. Transfer to the cyclization kettle, raise the temperature to 90°C, add p-toluenesulfonic acid, and continuously monitor the cyclization degree of the cyclized isoprene during the reaction process. After reaching the specified value, add pure water to stop. After several times of washing with pure water, the PH reaches neutral, add hydrogen peroxide, keep the temperature at 65°C, control the oxidation time, divide the water, wash with pure water three times, clean out the hydrogen peroxide, filter with a 0.2um frame filter, after repeated Concentrate to reach the specified solid content, transfer to 100-level purification workshop for photoresist configuration, add photosensitizer, additives and other raw materials, stir and filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com