Capacitive touch screen with gf1 structure and manufacturing method thereof

A technology of a capacitive touch screen and a manufacturing method, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of opaque silver glue line, high cost, low life efficiency, etc., and achieves simple manufacturing process, High-precision, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

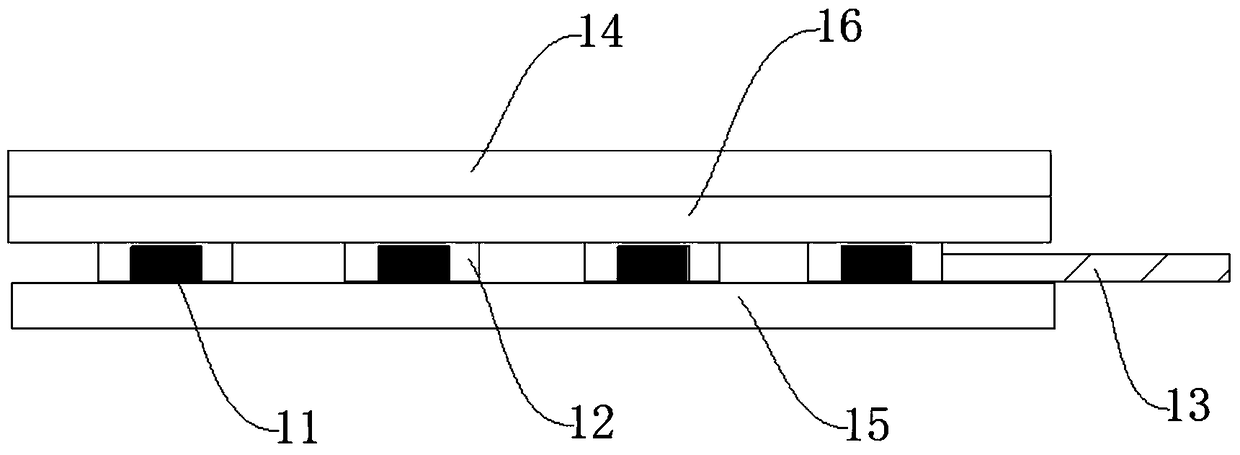

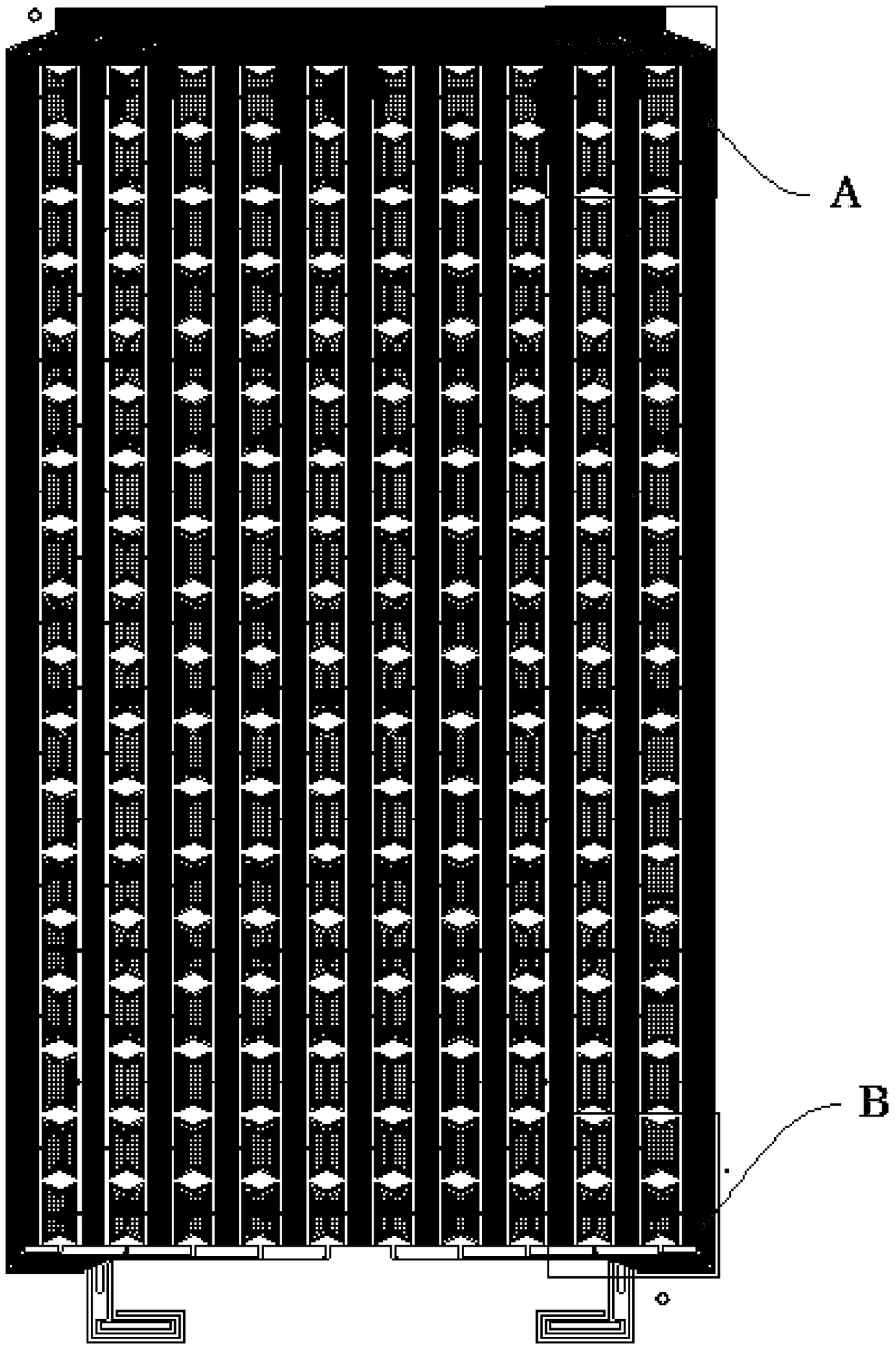

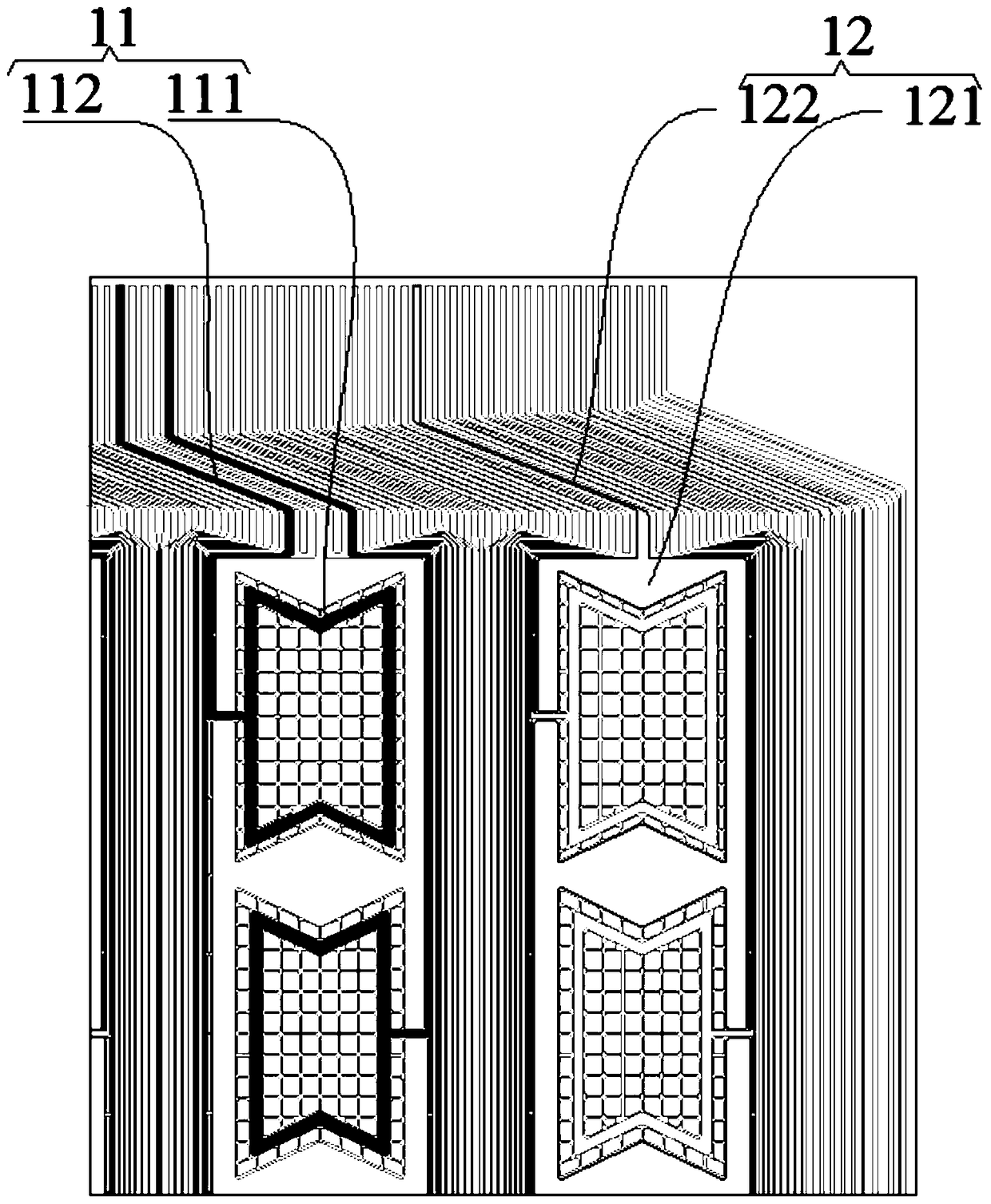

[0030] figure 1 A capacitive touch screen of the GF1 structure in this embodiment is shown. The capacitive touch screen of the GF1 structure includes an ITO film layer 15 , a flexible circuit board 13 , a cover glass 14 and an OCA optical adhesive layer 16 . Such as Figure 2-Figure 4 As shown, the ITO film layer 15 is provided with an integrally formed X-direction ITO circuit 11 and a Y-direction ITO circuit 12; the X-direction ITO circuit 11 includes an integrally formed X-direction ITO electrode line 111 and an X-direction ITO lead-out line 112. The ITO circuit 12 includes an integrally formed Y-direction ITO electrode line 121 and a Y-direction ITO lead-out line 122 . The X-direction ITO lead-out line 112 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com