A high-energy multi-element ion implanter

An ion implanter and multi-element technology, which is applied in the direction of electrical components, discharge tubes, circuits, etc., can solve the problems of increasing the insulation distance, the physical size of the equipment, the poor uniformity of ion implantation, and the increase in the complexity of the structure, so as to ensure the ion beam current Purity, simple and compact structure, energy-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

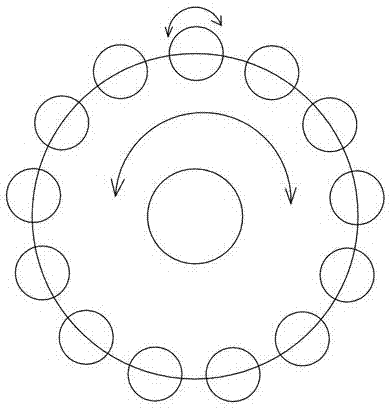

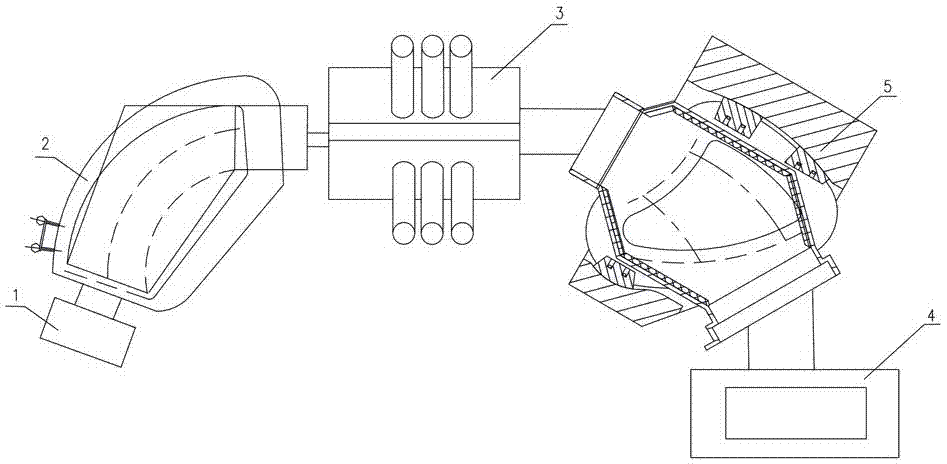

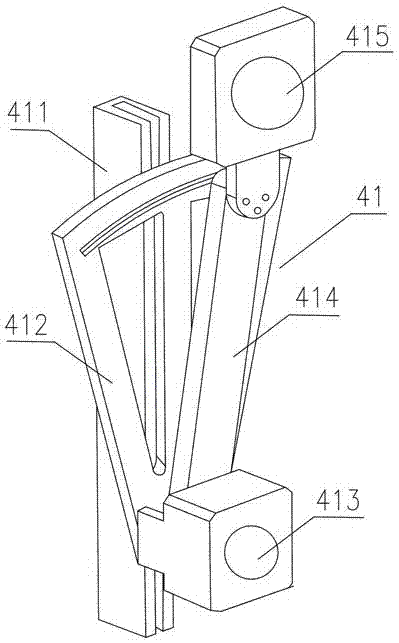

[0027] like Figure 2 to Figure 5 As shown, the present invention provides a high-energy multi-element ion implanter, including an ion source 1 , a mass analyzer 2 , a radio frequency acceleration system 3 and a target chamber 4 . The ion source 1 generates required ions, including: H, He, Ar, B, P, As, etc., which can be single charge, double charge and triple charge. The mass analyzer 2 receives the ions generated by the ion source 1, and realizes the ion screening function to obtain the required ions to ensure the purity of the ion species; at the same time, it partially focuses the transmitted ion beam to increase the beam transmission efficiency. After the mass analyzer 2 transmits the screened ion beam to the radio frequency acceleration system 3, the radio frequency acceleration system 3 accelerates the screened ion beam to accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com