Method for purifying isopropyl alcohol

A technology of isopropanol and feed materials, which is applied in the direction of organic chemical methods, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

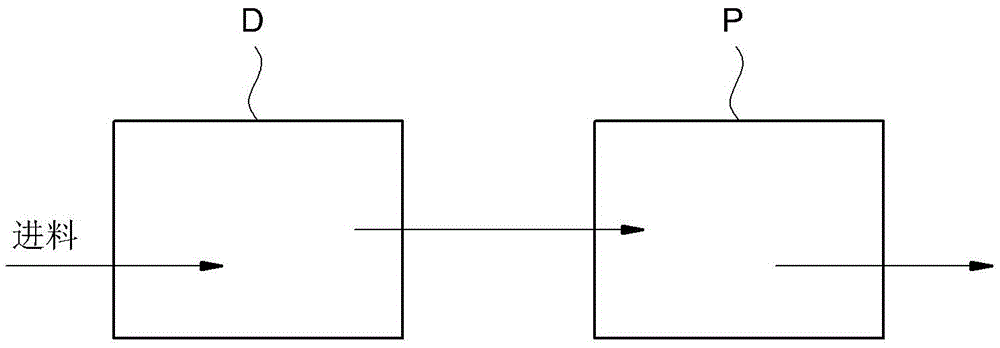

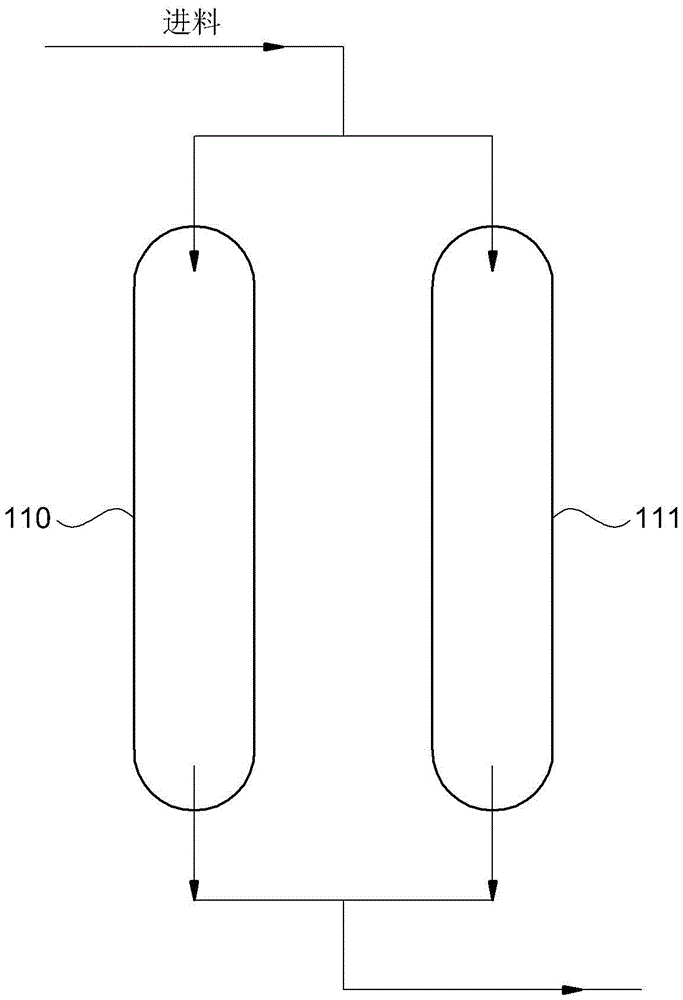

Method used

Image

Examples

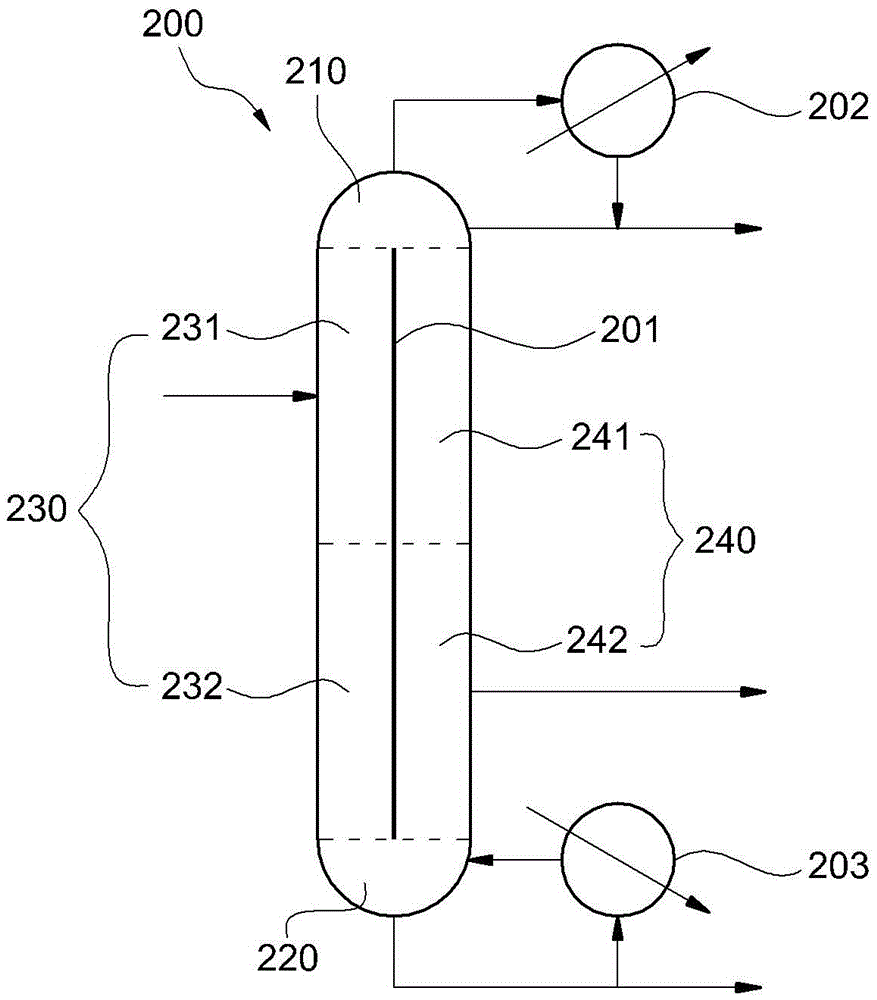

Embodiment 1

[0067] Such as Figure 4 Isopropanol (IPA) was purified using a dehydration unit and a dividing wall column (DWC) connected to the dehydration unit as shown in . Specifically, a device in which a membrane system and a tower packed with molecular sieves are sequentially connected is used as the dehydration device, a pervaporation system including a membrane (Pervatech company, HybSi membrane) device and a vacuum device is used as the membrane system, and a device with about A microporous zeolite 3A with an average effective pore size of about 3m is used as the molecular sieve 3 The packing volume of the two columns. Here, using a 3 / hr flow rate of nitrogen to the device for molecular sieve regeneration. A liquid feed comprising 98.6 wt% of IPA, about 3000 ppm of water and about 1.1 wt% of other impurities was used as feed. Feed was supplied to the dehydration unit at 90° C. to adjust the water content in the feed passing through the pervaporation system to about 1000 ppm,...

Embodiment 2

[0071] Purification was performed by the same method as described in Example 1 except that the reflux ratio of the top region was adjusted to 85.

Embodiment 3

[0073] Purification was performed by the same method as described in Example 1 except that the reflux ratio of the top region was adjusted to 76.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com