Anti-static and high-toughness oil absorbent roll

A technology of oil-absorbing cotton and high toughness, applied in the direction of adsorption of water/sewage treatment, alkali metal oxide/hydroxide, inorganic chemistry, etc., can solve the problems of secondary pollution, complex production process, high cost, etc., and achieve cost saving , Improve the strength and dimensional stability, and the effect of good oil absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

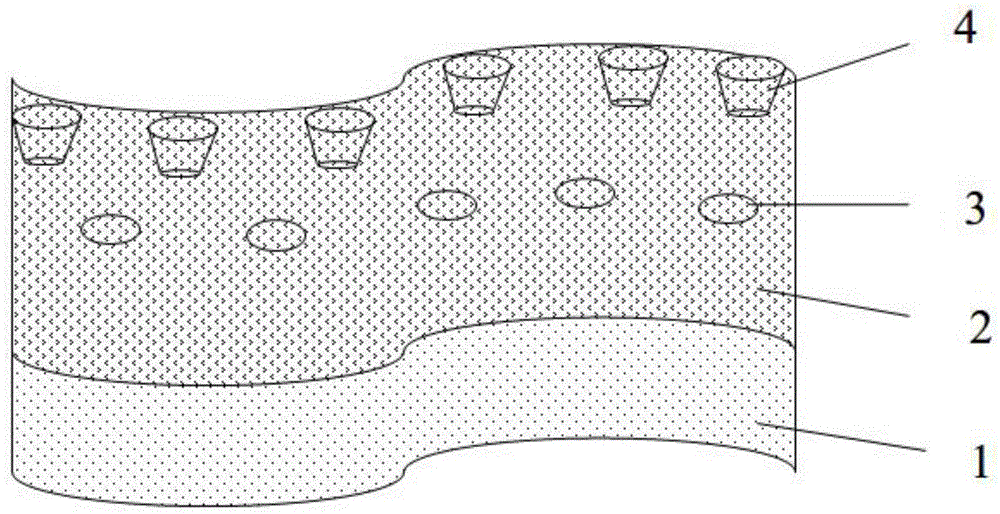

[0024] The present invention provides an antistatic high-toughness oil-absorbing cotton, which is characterized in that the oil-absorbing cotton includes a PE leak-proof layer 1 and an oil-absorbing layer 2, and the PE leak-proof layer 1 is compounded and fixed along the periphery of the oil-absorbing layer 2. The oil-absorbing layer 2 is formed on the surface of the PE leak-proof layer 1, the material of the oil-absorbing layer 2 is a polymer fiber, the surface and the inside of the oil-absorbing layer 2 are sponge-like, and the surface of the oil-absorbing cotton has a tapered hole 3. The oil-absorbing layer is produced by a needle-punching process, which specifically includes weaving long filaments formed of oil-absorbing polymer fibers and thermally bonded fibers together in the warp direction or weaving conductive fibers in the warp and weft directions to form a fiber web. After the fiber web is needled and then hot-rolled, the content of thermally bonded fibers in the fil...

Embodiment 2

[0028] The present invention provides an antistatic high-toughness oil-absorbing cotton, which is characterized in that the oil-absorbing cotton includes a PE leak-proof layer 1 and an oil-absorbing layer 2, and the PE leak-proof layer 1 is compounded and fixed along the periphery of the oil-absorbing layer 2. The oil-absorbing layer 2 is formed on the surface of the PE leak-proof layer 1, the material of the oil-absorbing layer 2 is a polymer fiber, the surface and the inside of the oil-absorbing layer 2 are sponge-like, and the surface of the oil-absorbing cotton has a tapered hole 3. The oil-absorbing layer is produced by a needle-punching process, which specifically includes weaving long filaments formed of oil-absorbing polymer fibers and thermally bonded fibers together in the warp direction or weaving conductive fibers in the warp and weft directions to form a fiber web. After the fiber web is needled and then hot-rolled, the content of thermally bonded fibers in the fil...

Embodiment 3

[0032] The present invention provides an antistatic high-toughness oil-absorbing cotton, which is characterized in that the oil-absorbing cotton includes a PE leak-proof layer 1 and an oil-absorbing layer 2, and the PE leak-proof layer 1 is compounded and fixed along the periphery of the oil-absorbing layer 2. The oil-absorbing layer 2 is formed on the surface of the PE leak-proof layer 1, the material of the oil-absorbing layer 2 is a polymer fiber, the surface and the inside of the oil-absorbing layer 2 are sponge-like, and the surface of the oil-absorbing cotton has a tapered hole 3. The oil-absorbing layer is produced by a needle-punching process, which specifically includes weaving long filaments formed of oil-absorbing polymer fibers and thermally bonded fibers together in the warp direction or weaving conductive fibers in the warp and weft directions to form a fiber web. After the fiber web is needled and then hot-rolled, the content of thermally bonded fibers in the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com