Method for preparing a phosphorus-containing polyethylene glycol terephthalate flame-retardant copolyester / organic intercalated alpha-ZrP nanocomposite

A technology of ethylene glycol phthalate and nano-composite materials, which is applied in the field of composite materials, can solve problems such as not being able to meet the use requirements of electrical components, and achieve the effects of easy promotion, overcoming uneven dispersion, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

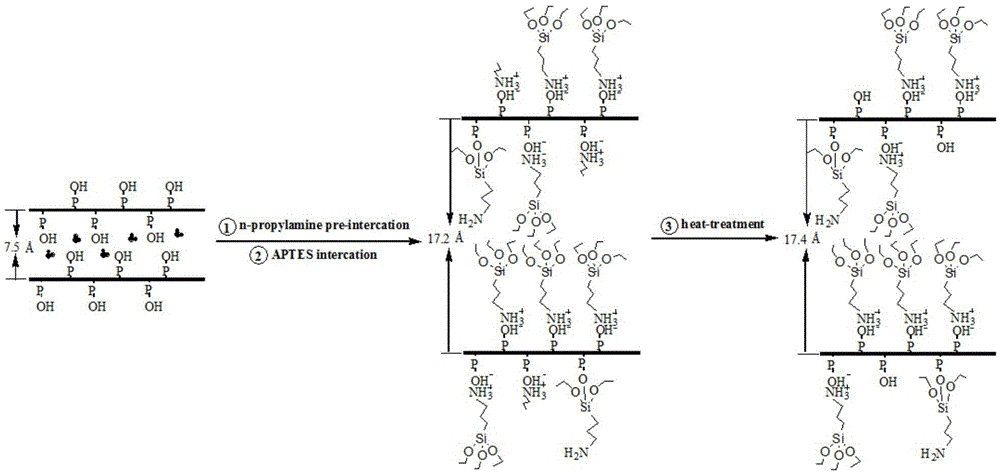

[0042] A preparation method of phosphorus-containing polyethylene terephthalate flame-retardant copolyester / organic intercalation α-ZrP nanocomposite material, such as figure 1 Shown is a schematic diagram of the process of preparing organically modified α-ZrP, in which α-ZrP is pre-intercalated with n-propylamine (n-propylamine), and then contacted with 3-aminopropyl-triethoxysilane (APTES). branching reaction, and finally through heat treatment (heat-treatment) to obtain organically modified α-ZrP, the steps are:

[0043] 1) Disperse α-ZrP in a mixed solution of water and ethanol with ultrasonic and mechanical stirring at room temperature, the ultrasonic power is 50W, and the time is 20min; the speed of mechanical stirring is 200r / min, and the time is 20min. The mass ratio of α-ZrP is 1:2; the concentration of α-ZrP after dispersion is 0.005g / ml;

[0044] 2) Add small molecule n-propylamine to react, the molar ratio of n-propylamine to α-ZrP is 1:2.0, and the reaction time ...

Embodiment 2

[0052] A preparation method of phosphorus-containing polyethylene terephthalate flame-retardant copolyester / organic intercalation α-ZrP nanocomposite, the steps are:

[0053] 1) Disperse α-ZrP in a mixed solution of water and ethanol with ultrasonic and mechanical stirring at room temperature, the ultrasonic power is 90W, and the time is 50min; the speed of mechanical stirring is 800r / min, and the time is 50min. The mass ratio of α-ZrP is 1:8; the concentration of α-ZrP after dispersion is 0.02g / ml;

[0054] 2) Add small molecule ethylamine to react, the molar ratio of ethylamine to α-ZrP is 1:4.0, and the reaction time of adding ethylamine is 1.8h;

[0055] 3) Add the silane coupling agent 3-aminopropyl-trimethoxysilane (APTMS) dropwise to continue the reaction; the mass ratio of the amount of APTMS added to α-ZrP is 2.0:1; the rate of addition is 1.5ml / min ; The time to continue the reaction is 8h;

[0056] 4) The modified α-ZrP can be obtained by separating, washing and d...

Embodiment 3

[0062] A preparation method of phosphorus-containing polyethylene terephthalate flame-retardant copolyester / organic intercalation α-ZrP nanocomposite, the steps are:

[0063] 1) Disperse α-ZrP in a mixed solution of water and ethanol with ultrasonic and mechanical stirring at room temperature, the ultrasonic power is 60W, and the time is 30min; the speed of mechanical stirring is 500r / min, and the time is 30min. The mass ratio of α-ZrP is 1:5; the concentration of α-ZrP after dispersion is 0.008g / ml;

[0064] 2) Add small molecule n-propylamine to react, the molar ratio of n-propylamine to α-ZrP is 1:2.2, and the reaction time of adding n-propylamine is 0.9h;

[0065] 3) Add the silane coupling agent γ-methyl-acryloyloxy-propyl-trimethoxysilane (MPMS) dropwise to continue the reaction; the mass ratio of the amount of MPMS added to α-ZrP is 1.0:1; The acceleration rate is 1.2ml / min; the time to continue the reaction is 5h;

[0066] 4) The modified α-ZrP can be obtained by sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com