A kind of high-strength cast magnesium alloy containing Zn and heavy rare earth gd and preparation method thereof

A technology for casting magnesium alloys and heavy rare earths, which can solve problems such as unstable performance and low strength of magnesium alloys by removing certain components, weighing instruments, and analyzing materials, so as to improve the effect, improve mechanical properties, The effect of improving the strength of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

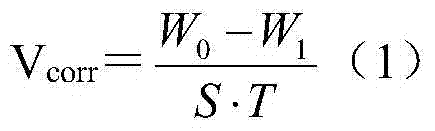

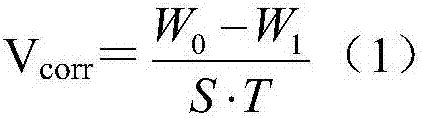

Image

Examples

Embodiment 1

[0045] This embodiment provides a cast magnesium alloy containing Zn and heavy rare earth Gd, the alloy composition (weight percentage) is: 15% Gd, 1% Zn, 0.5% Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0046] The preparation method of the above-mentioned cast magnesium alloy containing Zn and heavy rare earth Gd is as follows:

[0047] (1) According to the 500kg grade magnesium rare earth alloy purification process and ingot preparation technology: the above 500kg raw materials are firstly preheated to 200°C in an oven. The crucible is preheated to dark red after spraying the paint at room temperature. Put pure magnesium into SF 6 / CO 2 Preheat to melt in a dark red crucible under gas protection. Add pure Zn when the melting temperature of pure magnesium rises to about 690°C, and when the temperature continues to rise to about 720°C, slowly add Mg-87Gd master alloy into the melt, keep warm and stir. Then raise the furnace temperature to 780°C and the...

Embodiment 2

[0053] This embodiment provides a cast magnesium alloy containing Zn and heavy rare earth Gd, the alloy composition (weight percentage) is: 10% Gd, 0.5% Zn, 0.3% Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0054] The preparation method of the above-mentioned cast magnesium alloy containing Zn and heavy rare earth Gd is as follows:

[0055] (1) According to the 500kg grade magnesium rare earth alloy purification process and ingot preparation technology: the above 500kg raw materials are firstly preheated to 200°C in an oven. The crucible is preheated to dark red after spraying the paint at room temperature. Put pure magnesium into SF 6 / CO 2 Preheat to melt in a dark red crucible under gas protection. When the melting temperature of pure magnesium rises to about 690°C, pure Zn is added. When the temperature continues to rise to about 720°C, Mg-87Gd master alloy is slowly added to the melt, and stirred after keeping warm. Then raise the furnace temperatu...

Embodiment 3

[0061]This embodiment provides a cast magnesium alloy containing Zn and heavy rare earth Gd, the alloy composition (weight percentage) is: 15% Gd, 2% Zn, 0.5% Zr, impurity elements are less than 0.02%, and the rest is Mg.

[0062] The preparation method of the above-mentioned cast magnesium alloy containing Zn and heavy rare earth Gd is as follows:

[0063] (1) According to the 500kg grade magnesium rare earth alloy purification process and ingot preparation technology: the above 500kg raw materials are firstly preheated to 200°C in an oven. The crucible is preheated to dark red after spraying the paint at room temperature. Put pure magnesium into SF 6 / CO 2 Preheat to melt in a dark red crucible under gas protection. When the melting temperature of pure magnesium rises to about 690°C, pure Zn is added. When the temperature continues to rise to about 720°C, Mg-87Gd master alloy is slowly added to the melt, and stirred after keeping warm. Then raise the furnace temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com