Method for preparing flexible AZO thin film

A thin film and flexible technology, which is applied in the field of preparing flexible AZO films, can solve the problems of flexible substrate deformation, affecting film quality, substrate heating, etc., and achieve the effects of good film compactness, easy crystallization and growth, and temperature rise avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

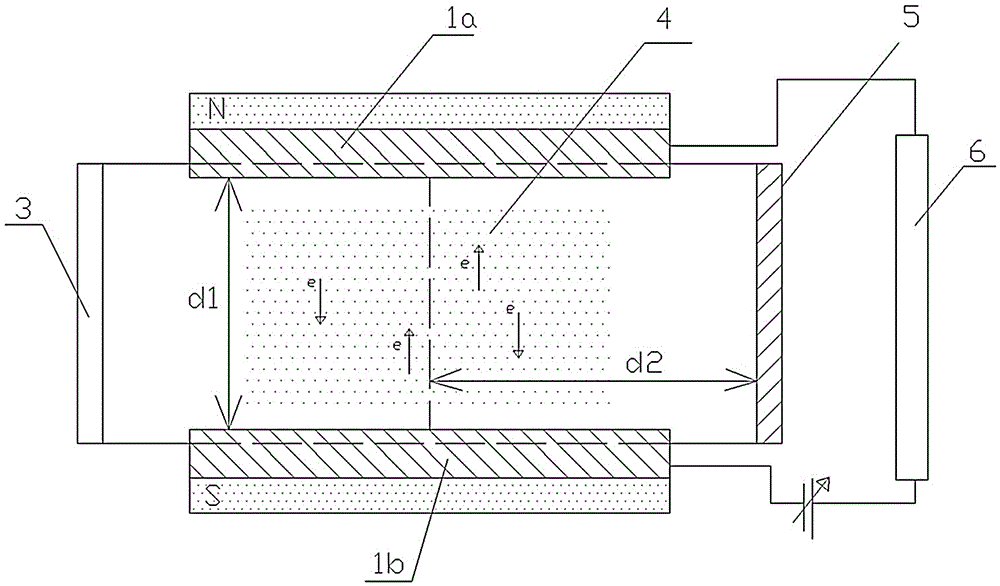

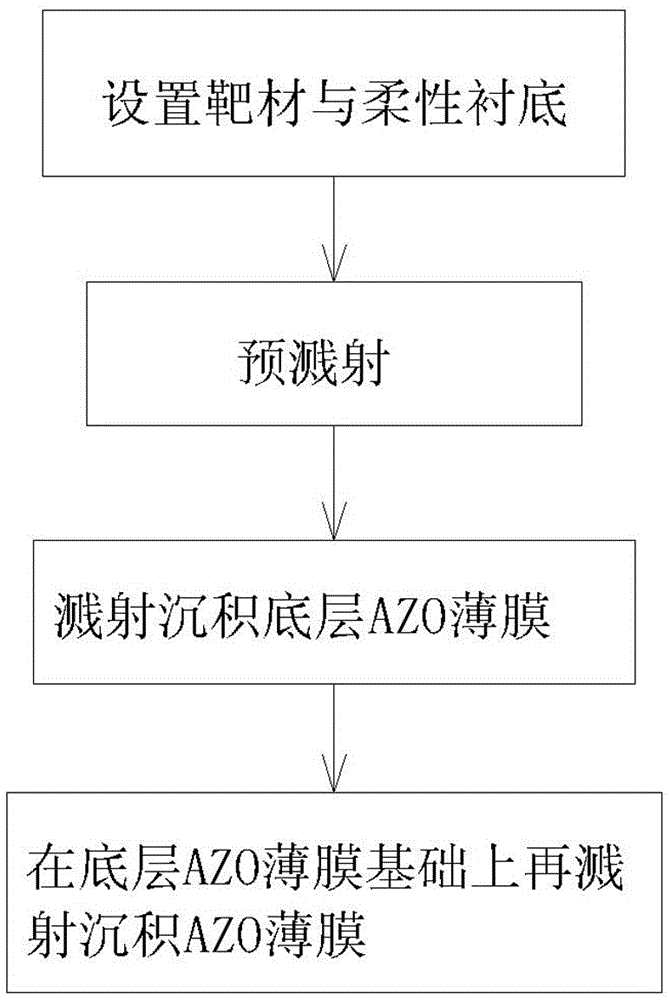

[0019] to combine figure 1 and figure 2 Shown, the invention provides a kind of method for preparing flexible AZO film, comprises the following steps:

[0020] a) The AZO target material of the magnetron sputtering device is set as two, that is, the upper AZO target material 1a and the lower AZO target material 1b, and the two targets are arranged opposite to each other up and down, and are connected by a copper conductor 3; the upper target material 1a The upper part is provided with a first magnet N, and the lower part of the lower target 1b is provided with a second magnet S, and the first magnet N and the second magnet S form a magnetic field between the two targets, and the direction of the magnetic field is perpendicular to the target; as a preferred , the distance d1 between the two targets is 70mm;

[0021] b) Set the flexible substrate 5 on the outside of the two AZO targets, use PET with a thickness of 0.8mm as the flexible substrate, make the flexible substrate 5...

Embodiment 2

[0027] Steps a to c of this embodiment are the same as in Embodiment 1, and the steps

[0028] d) The magnetron sputtering device is fed with 30sccm argon gas, the working pressure is 0.3Pa, the power is set to 250W, and 2.21W / cm 2 The power density of the flexible substrate 5 is sputtered, and the deposition time is 4min, so that the bottom AZO film with a thickness of 65nm is grown on the flexible substrate 5;

[0029] e) Increase the power of the magnetron sputtering device to 500W at 4.42W / cm 2 The power density of the flexible substrate is sputtered, and the deposition time is 11min, so that the flexible substrate grows a layer of AZO film with a thickness of 280nm on the basis of the underlying AZO film, and the final AZO\PET film is obtained.

[0030] The AZO / PET film obtained above was subjected to transmittance test, resistivity test and XRD test respectively. The average transmittance of visible light was 83%, and the resistivity was 5.7*10 -3 Ω·cm, XRD pattern sho...

Embodiment 3

[0032] Steps a to c of this embodiment are the same as in Embodiment 1, and the steps

[0033] d) The magnetron sputtering device is passed into 30sccm argon gas, the working pressure is 0.3Pa, the power is set to 300W, and 2.65W / cm 2 The power density of the flexible substrate 5 is sputtered, and the deposition time is 4min, so that the bottom AZO film with a thickness of 80nm is grown on the flexible substrate 5;

[0034] e) Increase the power of the magnetron sputtering device to 600W at 5.30W / cm 2 The power density of the flexible substrate is sputtered, and the deposition time is 10min, so that the flexible substrate grows a layer of AZO film with a thickness of 300nm on the basis of the underlying AZO film to obtain the final AZO\PET film.

[0035] The AZO / PET film obtained above was subjected to transmittance test, resistivity test and XRD test respectively. The average transmittance of visible light was 82.7%, and the resistivity was 4.8*10 -3 Ω·cm, XRD pattern shows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com