Anti-corrosion mud pump

A mud pump and body technology, applied in the field of anti-corrosion mud pumps, can solve the problems of improving the pump body, not being able to apply the plunger pump, and not being able to enhance the use efficiency of the pump body, and achieve the effect of improving efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

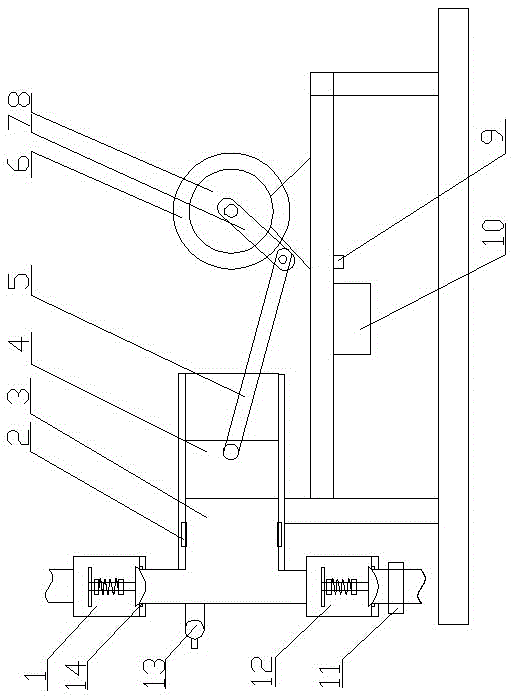

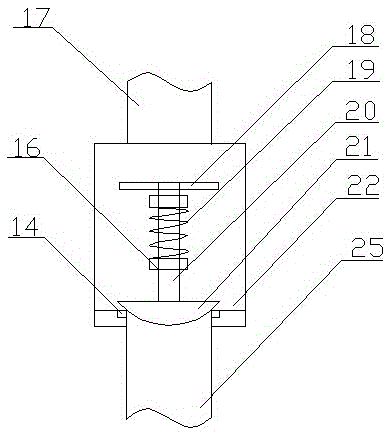

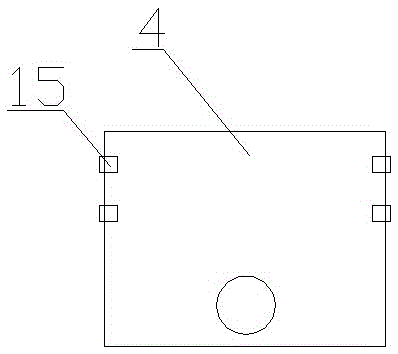

[0043] Embodiment 2: An anti-corrosion mud pump, including a pump body, a drive mechanism located at the rear of the pump body and a control mechanism connected to the drive mechanism, the pump body includes a cavity 3, a piston 4, a feed Valve 12 and discharge valve 1, the piston 4 is arranged in the cavity 3, the feed valve 12 and the discharge valve 1 are respectively arranged at the upper part and the lower part of the front end of the cavity 3, and the discharge valve 1 and the feed valve 12 are provided with a sealing module, and the inner wall of the cavity 3 is provided with a number of annular grooves 2, and a lubricating ring is arranged in the annular groove 2.

[0044] Described drive mechanism comprises drive motor 6, flywheel 8, crank 7 and connecting rod 5, and described drive motor 6 is connected with crank 7, and described crank 7 is connected with flywheel 8, and described crank 7 is movably connected with connecting rod 5 , the lubricating ring is a graphite...

Embodiment 3

[0052] Embodiment 3: An anti-corrosion mud pump, including a pump body, a drive mechanism located at the rear of the pump body and a control mechanism connected to the drive mechanism, the pump body includes a cavity 3, a piston 4, a feed Valve 12 and discharge valve 1, the piston 4 is arranged in the cavity 3, the feed valve 12 and the discharge valve 1 are respectively arranged at the upper part and the lower part of the front end of the cavity 3, and the discharge valve 1 and the feed valve 12 are provided with a sealing module, and the inner wall of the cavity 3 is provided with a number of annular grooves 2, and a lubricating ring is arranged in the annular groove 2.

[0053] Described drive mechanism comprises drive motor 6, flywheel 8, crank 7 and connecting rod 5, and described drive motor 6 is connected with crank 7, and described crank 7 is connected with flywheel 8, and described crank 7 is movably connected with connecting rod 5 , the lubricating ring is a graphite...

Embodiment 4

[0063] Embodiment 4: An anti-corrosion mud pump, including a pump body, a drive mechanism located at the rear of the pump body and a control mechanism connected to the drive mechanism, the pump body includes a cavity 3, a piston 4, a feed Valve 12 and discharge valve 1, the piston 4 is arranged in the cavity 3, the feed valve 12 and the discharge valve 1 are respectively arranged at the upper part and the lower part of the front end of the cavity 3, and the discharge valve 1 and the feed valve 12 are provided with a sealing module, and the inner wall of the cavity 3 is provided with a number of annular grooves 2, and a lubricating ring is arranged in the annular groove 2.

[0064] Described drive mechanism comprises drive motor 6, flywheel 8, crank 7 and connecting rod 5, and described drive motor 6 is connected with crank 7, and described crank 7 is connected with flywheel 8, and described crank 7 is movably connected with connecting rod 5 , the lubricating ring is a graphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com