Intelligently controlled integrated variable frequency motor system

A variable frequency motor and intelligent control technology, applied in the control system, connected with the control/drive circuit, AC motor control, etc., can solve the problem that the real-time monitoring of a large-scale machine network cannot be realized, the cable box plug-in is vulnerable to wear and water corrosion, Single data connection and other problems, to achieve the effect of shortening the length of the connecting line, improving work stability, and small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] Such as figure 1 As shown, the present invention includes a variable frequency motor D, a handheld terminal A, an operation panel B, and a remote control terminal C.

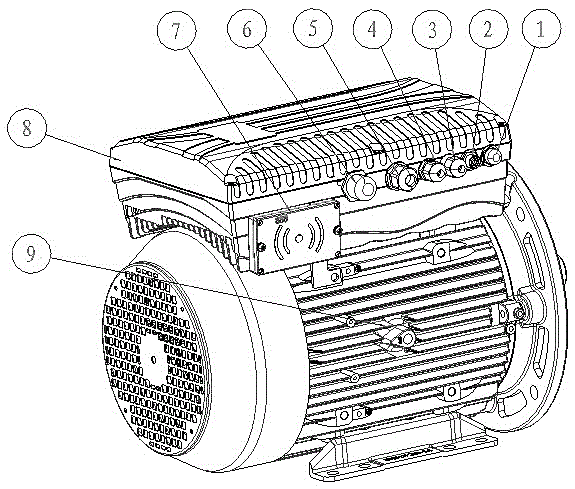

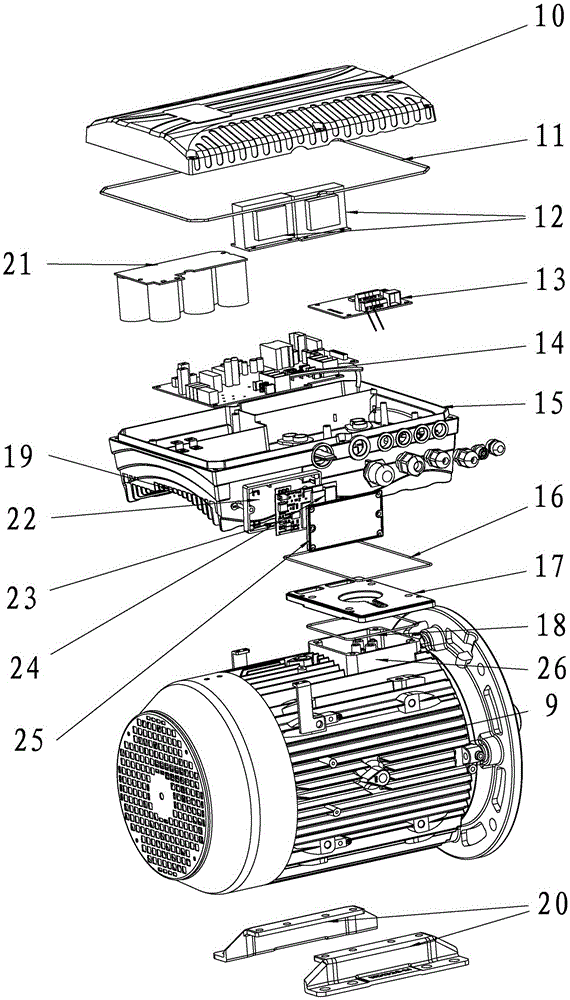

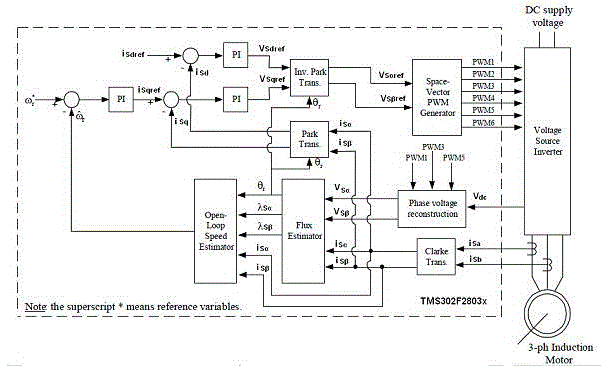

[0041] Such as figure 2 , image 3 As shown, the variable frequency motor D includes an indicator light 1, an aviation connector 2, an IO port 3, a 485 communication port 4, a power input port 5, a Bluetooth module 6, a GPRS module 7, a controller 8, and a motor 9. The plate 17 is fixed on the top of the motor 9 by screws, and the motor fan is used to dissipate heat. Devices in the controller include: power drive module 14, control board 13, reactor 12, capacitor module 21 and other electronic power devices. A third sealing ring 18 is placed between the motor 9 and the adapter plate 17, and a second sealing ring 16 is placed between the adapter plate 17 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com