Double-woven fabric with cross closed structure and weaving method of double-woven fabric

A technology of double-layer fabric and closed structure, which is applied in fabrics, multi-strand fabrics, textiles, and papermaking. It can solve the problems of affecting the quality of clothing, low production efficiency, and differences in the thickness of down jackets, so as to improve market competitiveness and save labor costs. , Reduce the effect of sewing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

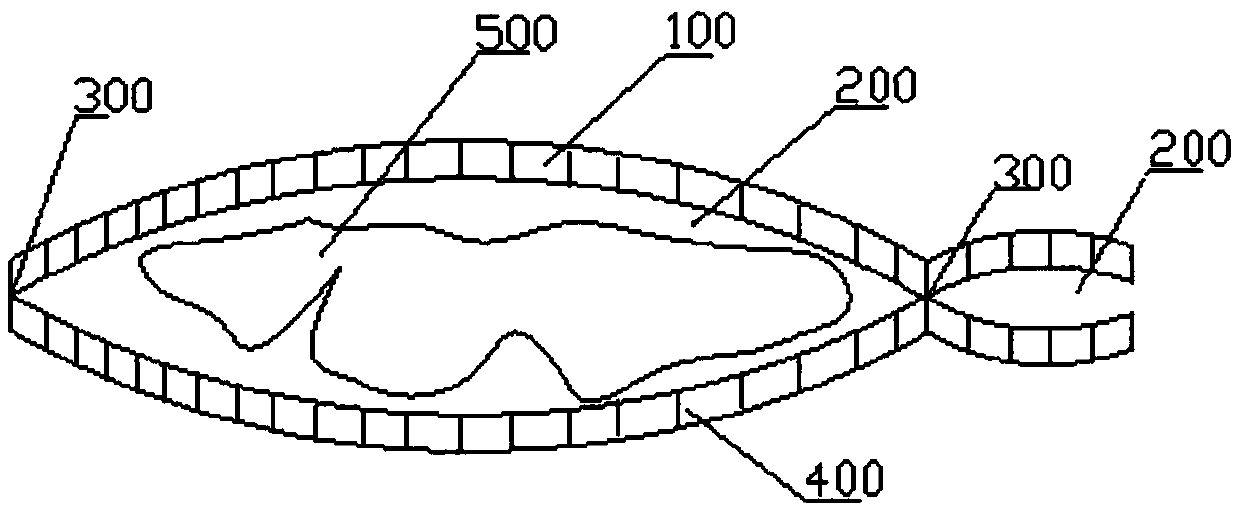

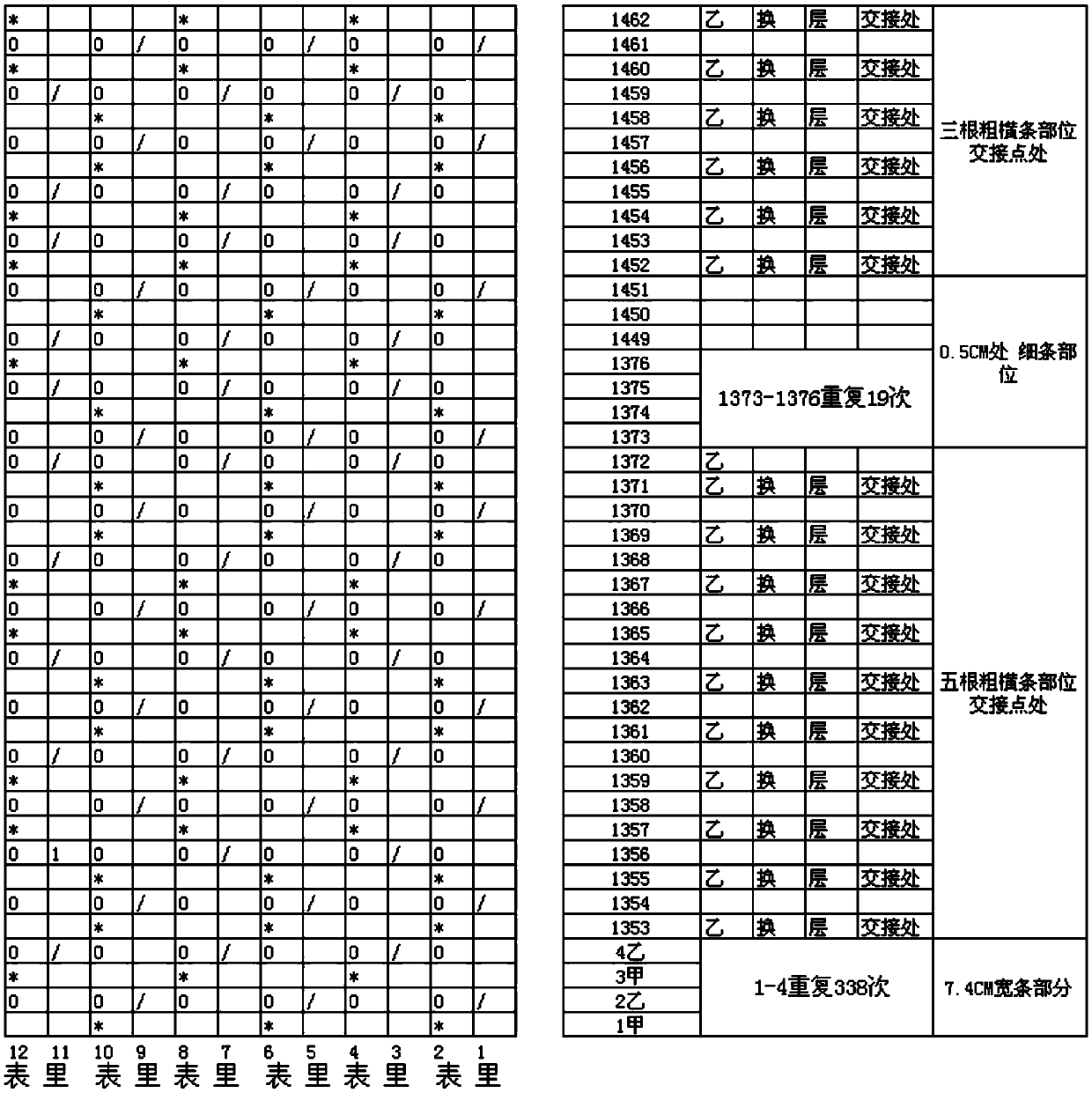

[0040] like figure 1 As shown, the present invention provides a double-layer fabric with a cross-closed structure, including two layers of fabrics 100 and 400 on the surface and the back, and part of the warp and weft of the surface fabric 100 and part of the warp and weft of the inner fabric 400 are interwoven Together they form the sealing layer 300 .

[0041] Hereinafter, the warp and weft of the surface fabric 100 are referred to as surface warp and weft respectively; the warp and weft of the inner fabric 400 are respectively referred to as inner warp and inner weft.

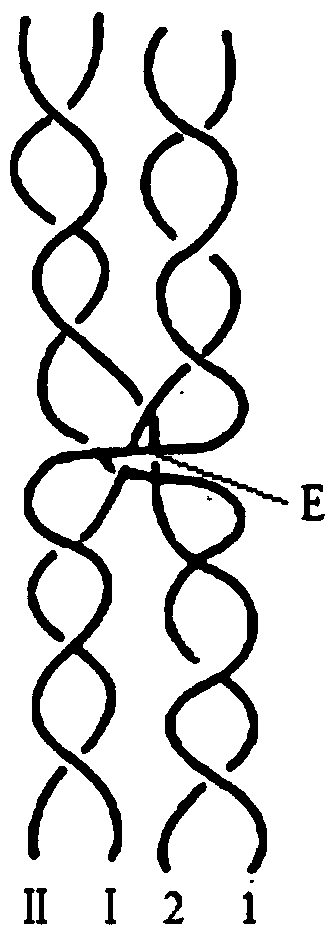

[0042] It should be noted that the sealing layer 300 can be in one or more than two locations, wherein the weaving structure of the sealing layer in each location can be the same or different, and can be formed after one interweaving such as figure 2 As shown, it can also be two or more interleaving forms such as image 3 shown.

[0043] like figure 1 As shown, there are more than two sealing layers, an...

Embodiment 2

[0070] As a preferred solution of the above embodiment, the sealing layer is formed by merging and interweaving warp threads and weft threads of the inner and outer layers of fabrics according to the yarn density and the ratio of warp and weft threads respectively. like figure 2 As shown in the figure: outer warp: inner warp = 1:1, outer weft: inner weft = 1:1, both the surface weave and the inner weave are plain weave. 1 and 2 respectively represent the surface longitude and surface latitude; Ⅰ and Ⅱ represent the inner longitude and inner latitude respectively. In the figure, the upper and lower positions of the surface warp and the interior warp and the surface weft and the interior weft are exchanged, and the junction point E is the closed layer.

Embodiment 3

[0072] As a preferred solution of the above embodiment, the outer and inner fabrics are exchanged through the sealing layer, so that a double-layered fabric with outer and inner layers can be obtained.

[0073] It should be noted that the structure of the surface layer fabric and the inner layer fabric may be the same or different. Preferably, the structures of the surface layer fabric and the inner layer fabric are plain weave, square box or twill weave respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com