Cardiac coronary artery stent

A technology for coronary arteries and hearts, applied in the cardiovascular field, can solve the problems of complex structure, high difficulty, and high processing difficulty, and achieve the effects of easy stent removal, direct and convenient manufacturing, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

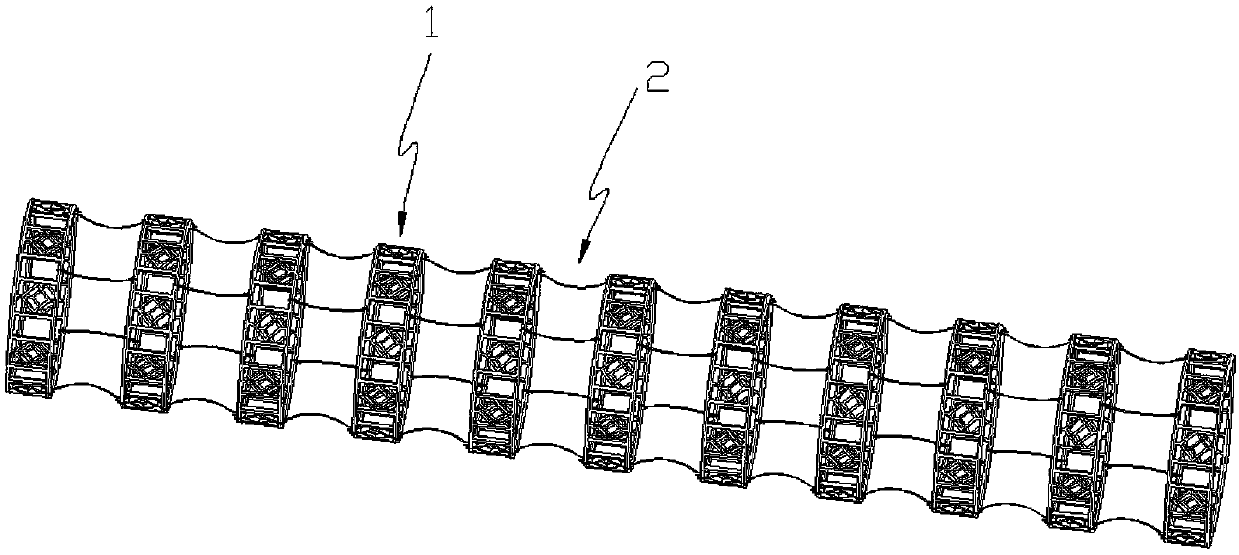

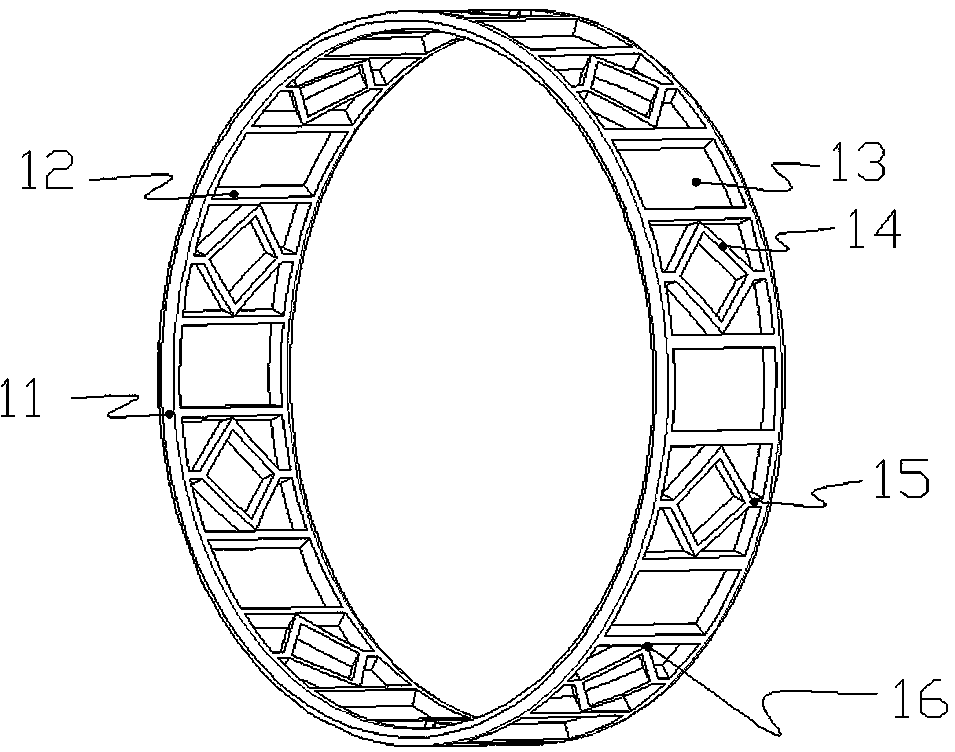

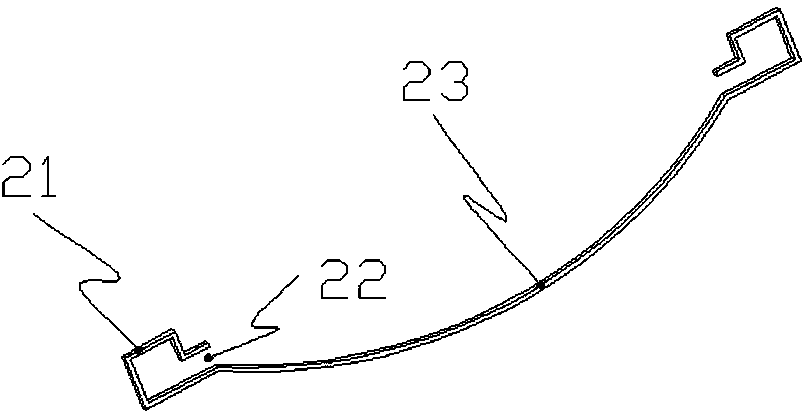

[0032] Refer to the attached figure 1 , figure 1 The middle is the assembly state of the vascular stent, which is a cylindrical structure as a whole, or a structure similar to a cylinder. Since the connecting body 2 is an elastic body, it has the ability to be bent to adapt to the physiological conditions of different vascular parts. structure.

[0033] If the heart coronary stent is regarded as a cylinder as a whole, the centrifugal and centripetal should be understood by those skilled in the art.

[0034] At the same time, the basic structure defined by the ring 1 is matched with a shaft, a ring, so that the circumferential direction and the axial direction should be understood by those skilled in the art.

[0035] See attached figure 1 , a heart coronary artery stent (hereinafter referred to as a stent for short) shown in the figure, its basic structure should include the following structures:

[0036] There are 11 rings 1 in the figure. It can be seen that ring 1 is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com