Machine integrating demagnetization and smashing and method for smashing hard disc piece, u flash disc, IC card and optical disc

A hard disk platter and all-in-one machine technology, which is applied in the field of degaussing and crushing all-in-one machine and hard disk degaussing and crushing, which can solve the problems of poor confidentiality and large crushed particles (generally not less than 20×40mm), and achieve low discharge voltage and guarantee The effect of using diversity and guaranteeing the degaussing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

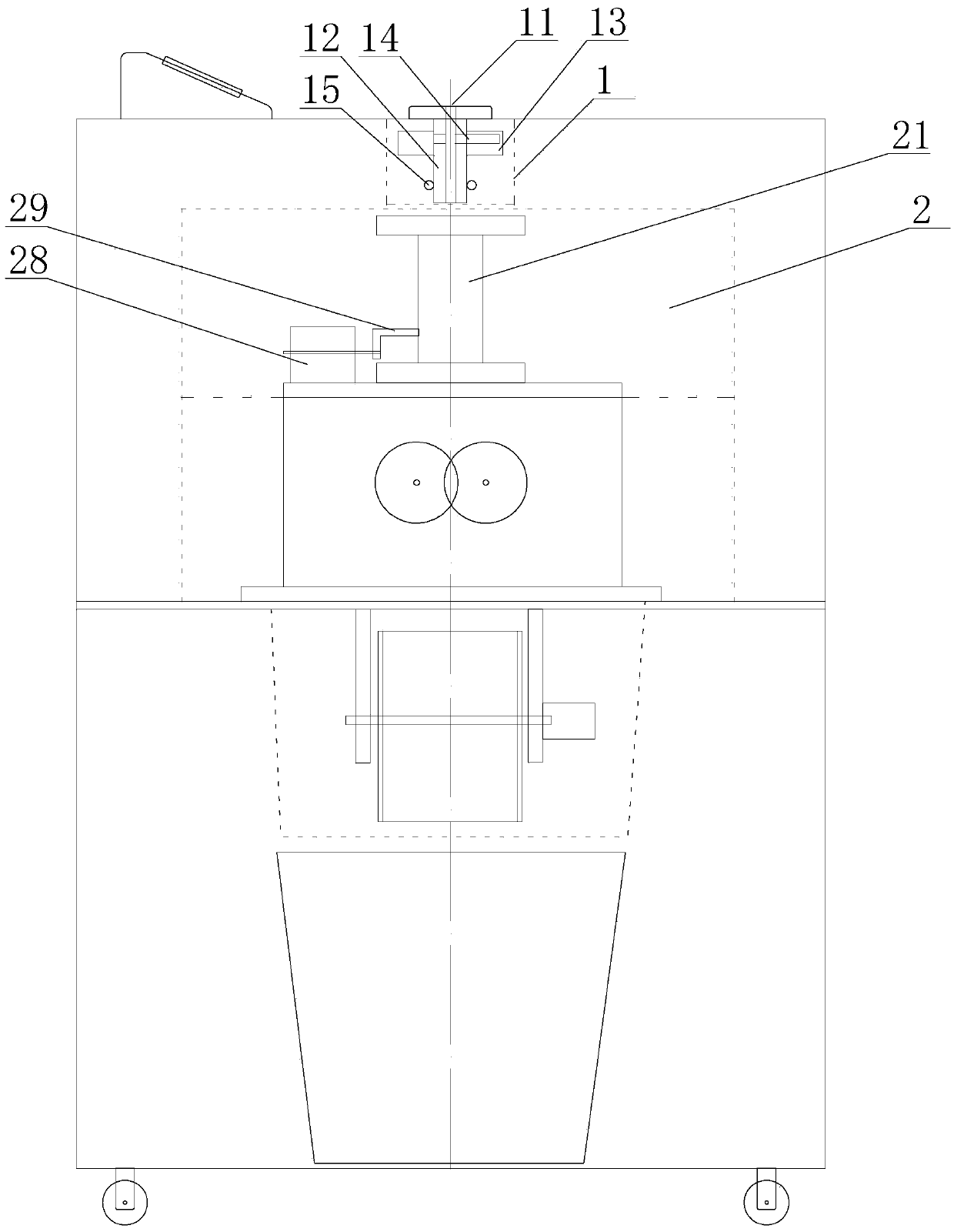

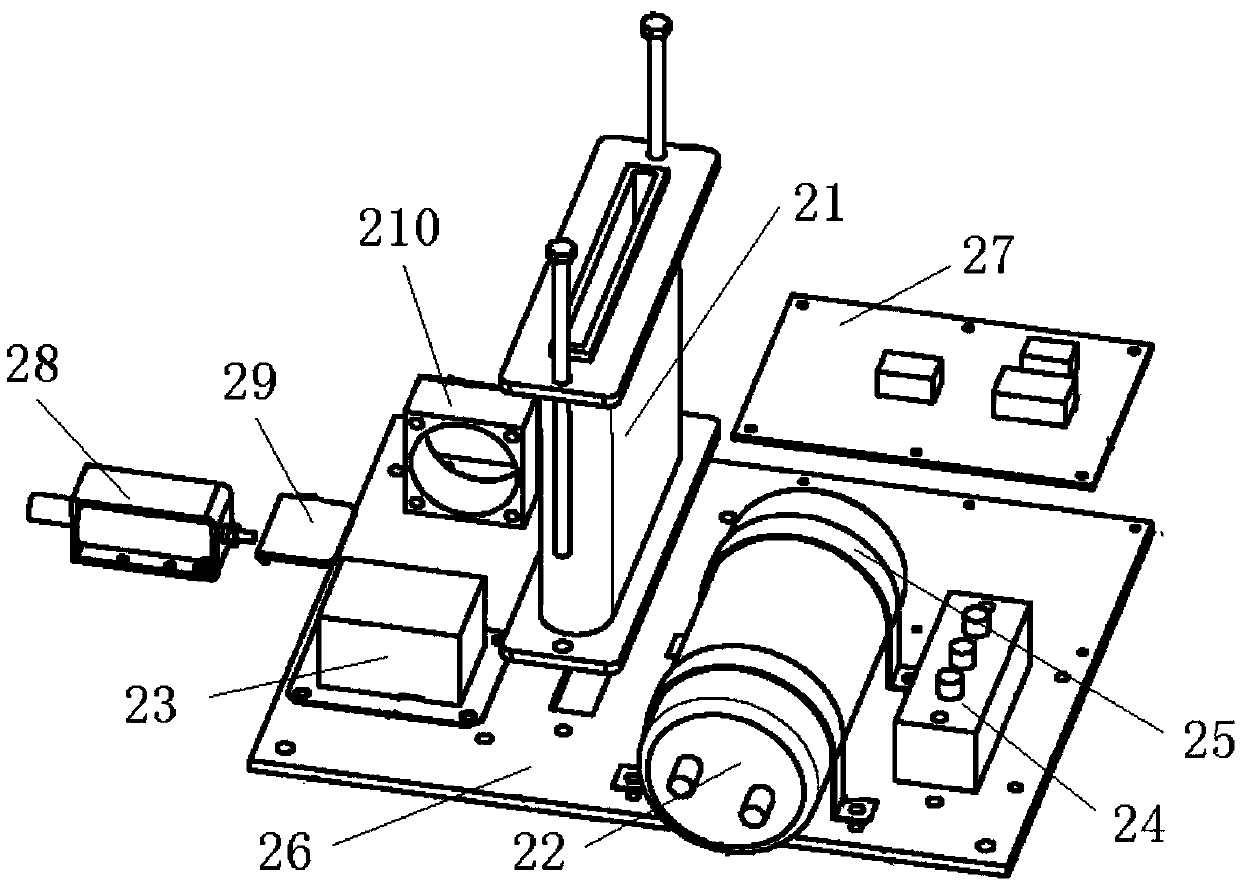

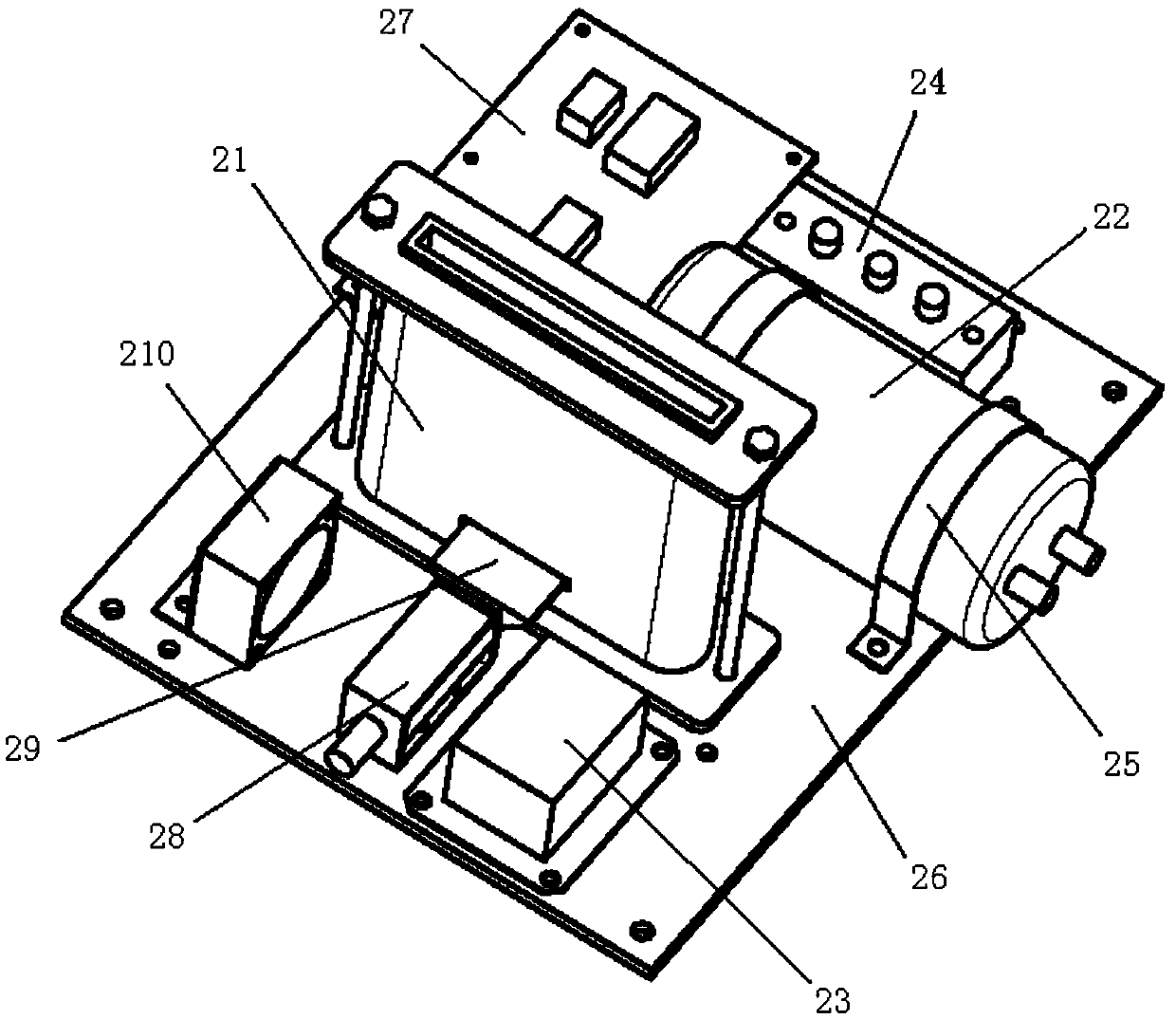

[0050] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention; figure 2 It is a schematic diagram of dismantling the three-dimensional structure of the hard disk disc degaussing module in Embodiment 1 of the present invention; image 3 It is a structural schematic view of the hard disk disc degaussing module in Embodiment 1 of the present invention viewed from another angle; in the figure, the meanings indicated by each reference mark are as follows: 1, feeding device; 11, feeding inlet; 12, feeding cylinder 13. Feed electromagnet; 14. Feed block; 15. Feed sensor; 2. Hard disk degaussing module; 21. Degaussing coil; 22. Energy storage capacitor; 23. Transformer; 24. Thyristor diode 25. Energy storage capacitor straps; 26. Degaussing module bottom plate; 27. Degaussing circuit board; 28. Degaussing discharge electromagnet; 29. Disc block; 210. Cooling fan; 3. Crushing module;

[0051] A degaussing and pulverizing integrated machine, comprisi...

Embodiment 2

[0082] Figure 4 It is a schematic structural view of the degaussing and pulverizing all-in-one machine according to Embodiment 2 of the present invention; Figure 5 It is a schematic diagram of the three-dimensional structure of the crushing module; in the figure, the meanings of the newly appearing reference signs are as follows: 31, the crushing motor; 32, the crushing knife set; 33, the vertical plate of the crushing module; 34, the bottom plate of the crushing module; 35, the transmission gear ; 36, scrap baffle; 5, touch screen.

[0083] The difference between this embodiment and embodiment 1 is:

[0084] A crushing module 3 is also provided below the hard disk degaussing module 2, the hard disk degaussing module 2 has a degaussing outlet, and the crushing module 3 has a crushing inlet, and the crushing inlet is located below the degaussing outlet.

[0085]A crushing module 3 is also installed on the base plate of the hard disk disc degaussing module 2, and the crushin...

Embodiment 3

[0108] Figure 6 It is a schematic structural view of the degaussing and pulverizing all-in-one machine according to Embodiment 3 of the present invention; Figure 7 is a schematic structural diagram of the sorting mechanism; in the figure, the meanings of the new reference signs are as follows:

[0109] 4. Sorting mechanism; 41. Sorting flap; 42. Sorting motor; 43. First waste collection bucket; 44. Second waste collection bucket.

[0110] The difference of this embodiment with respect to Embodiment 2 is that: a sorting mechanism 4 is also installed on the lower surface of the crushing module base plate 34, and a first waste collection bucket 43 and a second waste collection bucket 44 are also arranged below the sorting mechanism 4 ( Figure 6 In, because the problem of angle of view has only drawn a waste material collection bucket), sorting mechanism 4 comprises sorting motor 42 and is used for the sorting machine that fragments are selectively introduced into the first wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com