An electromagnetic induction heating type 3D printer extrusion nozzle

An electromagnetic induction heating and 3D printer technology, applied in the field of 3D printing nozzles, can solve the problems of easy clogging of extrusion nozzles and other problems of filament output efficiency, and achieve the effect of preventing low filament output efficiency, ensuring uniformity, and improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

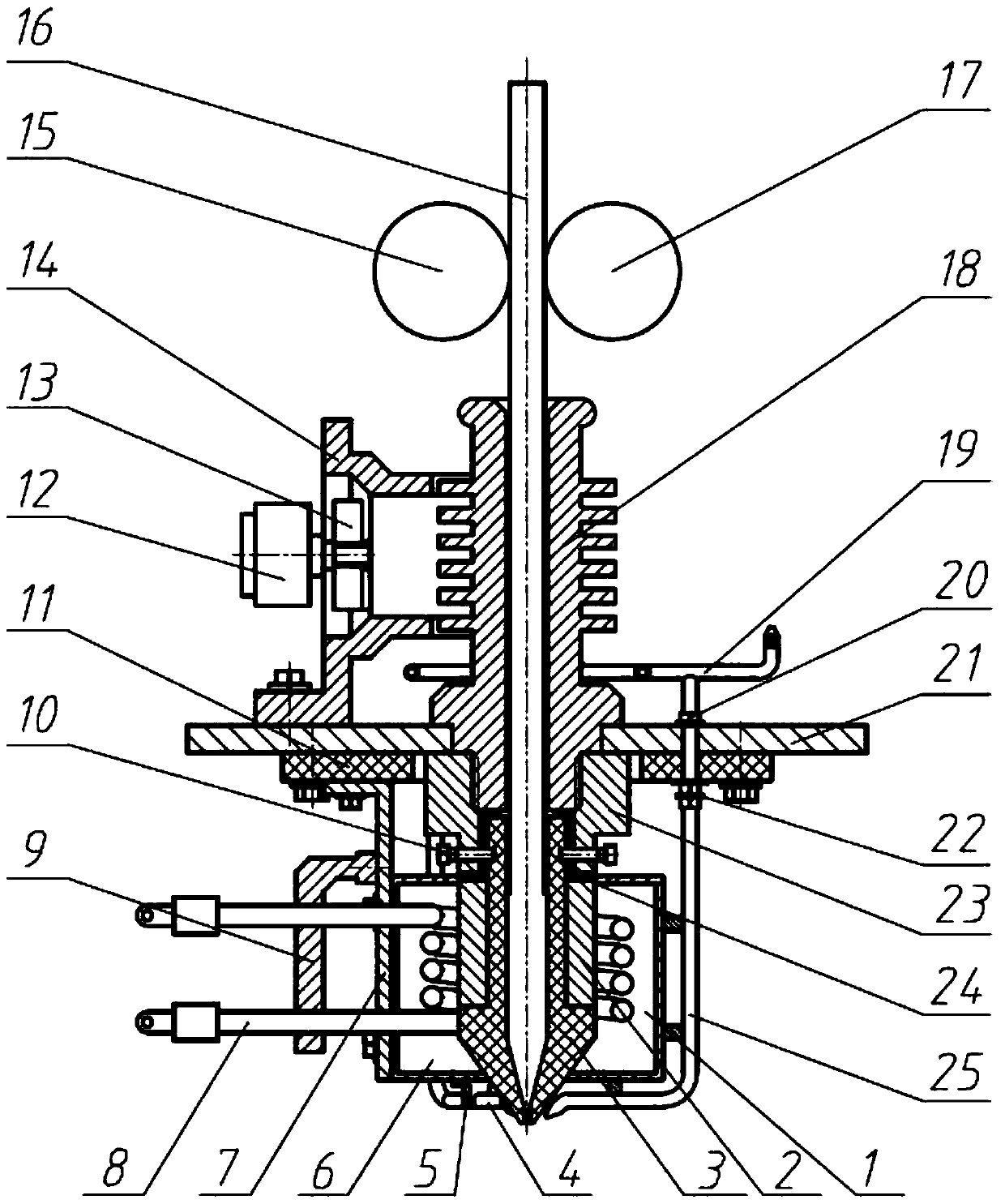

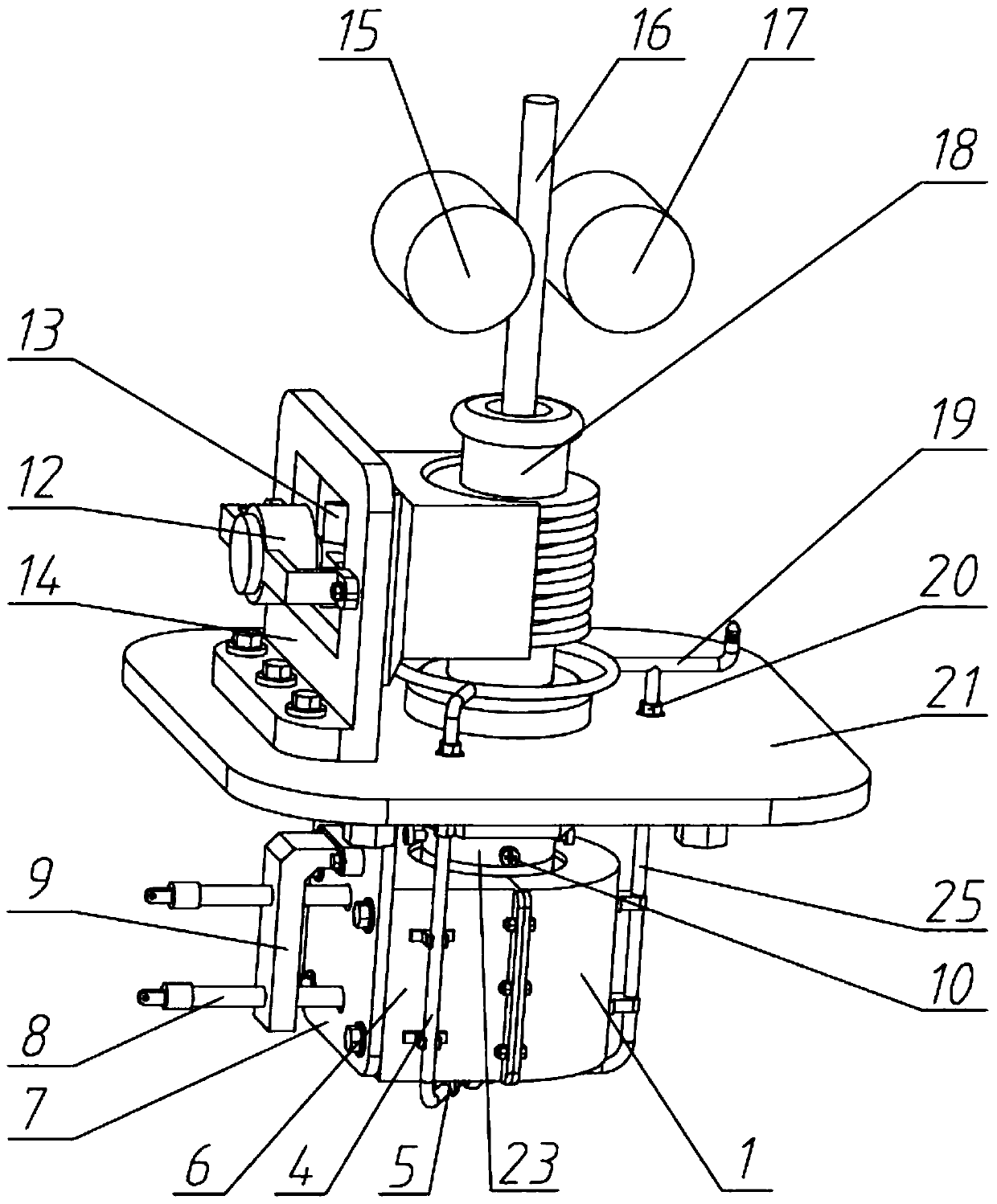

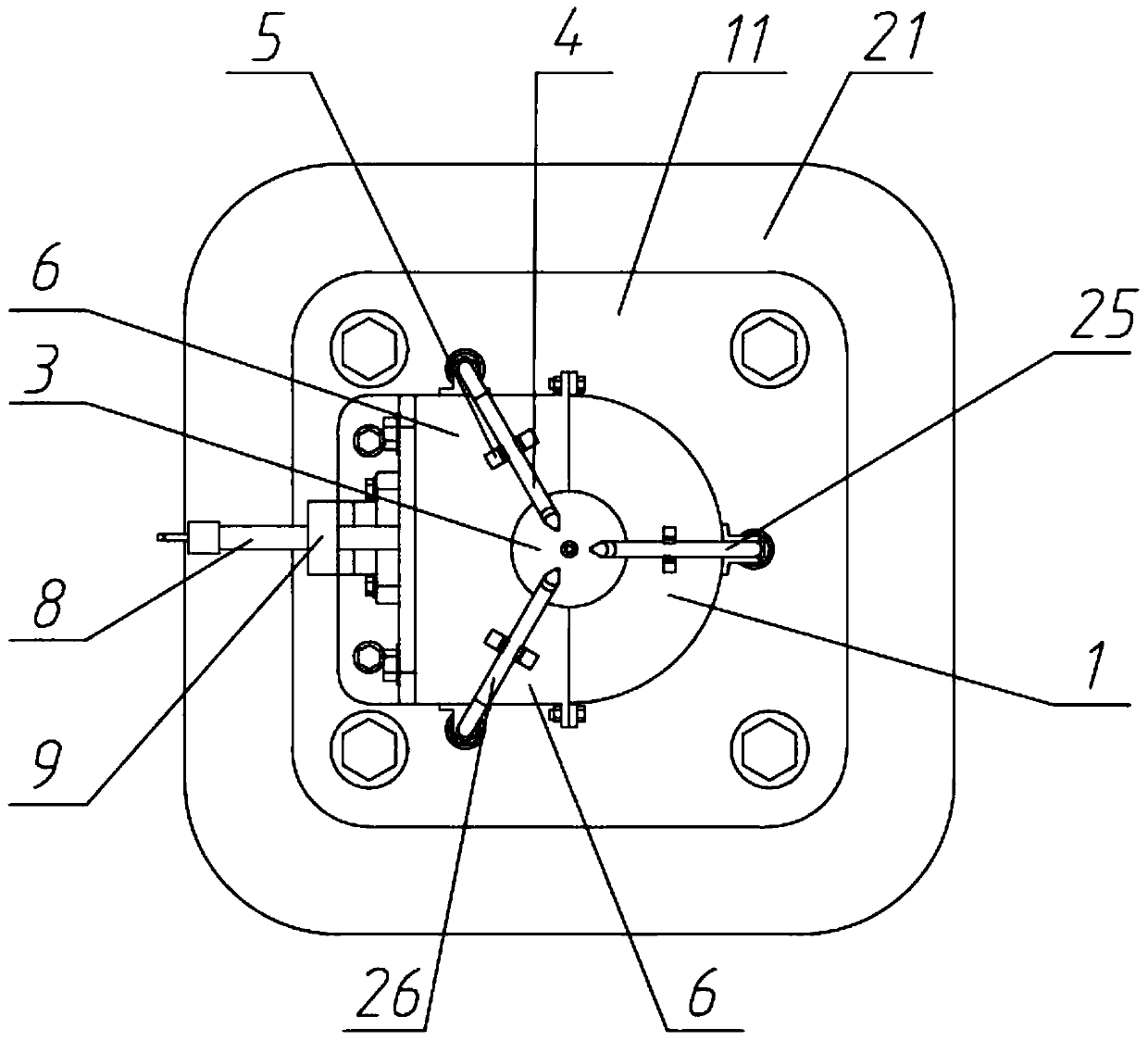

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] combine figure 1 , the present invention is mainly composed of five parts: a combined nozzle, an electromagnetic induction heating device, a cooling device, a feeding device and a protective gas channel; including a shielding cover II 1, an annular metal block 2, a ceramic nozzle 3, an air outlet pipe II 4, and an outlet pipe bracket 5. Shielding cover I 6, supporting frame 7, electromagnetic induction coil 8, coil fixing frame 9, fastening screw 10, heat shield 11, motor 12, fan blade 13, motor fixing frame 14, roller I 15, wire consumables 16. Roller II 17, also includes throat pipe 18, air intake pipe 19, pipe joint I 20, support plate 21, pipe joint II 22, nozzle fixing ring 23, high temperature resistant heat insulating ceramic ring 24, air outlet pipe I 25, air outlet pipe III 26: The combined nozzle and cooling device are installed on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com