Temperature monitor system for soldering longitudinal joint of cylinder of pressure container

A technology of longitudinal seam welding and pressure vessel, which is applied in the field of temperature monitoring system for longitudinal seam welding of pressure vessel barrels, can solve the problems of low measurement accuracy and discontinuous manual measurement, so as to ensure reasonable operation and avoid inaccurate temperature measurement. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The concrete implementation process of the present invention is described in detail below in conjunction with accompanying drawing:

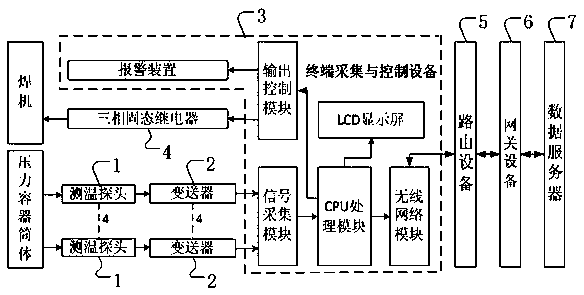

[0013] Such as figure 1 As shown, the temperature monitoring system for welding the longitudinal seam of the pressure vessel cylinder of the present invention includes a temperature measuring probe 1, a transmitter 2, a terminal acquisition and control device 3, a three-phase solid state relay 4, a routing device 5, and a gateway device 6 and data server 7.

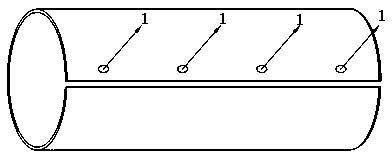

[0014] Combined with the requirements for the range of preheating temperature, interlayer temperature and afterheating temperature in the welding process of the longitudinal seam of the pressure vessel cylinder, in the present invention, the temperature measuring probe 1 selects a K-type thermocouple, and the transmitter 2 also selects a K-type thermocouple transmitter. Such as figure 2 As shown, four magnetic K-type temperature measuring probes 1 are equally spaced and adsorbed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com