High-altitude working platform for line construction

A kind of high-altitude work platform and platform technology, which is applied in the direction of overhead line/cable equipment, lifting equipment safety device, lifting device, etc., can solve the problems of one sinking, overall torsion, and reduce the labor intensity of construction personnel, so as to shorten the construction period. The effect of saving time, reducing labor intensity, and facilitating the replacement of construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

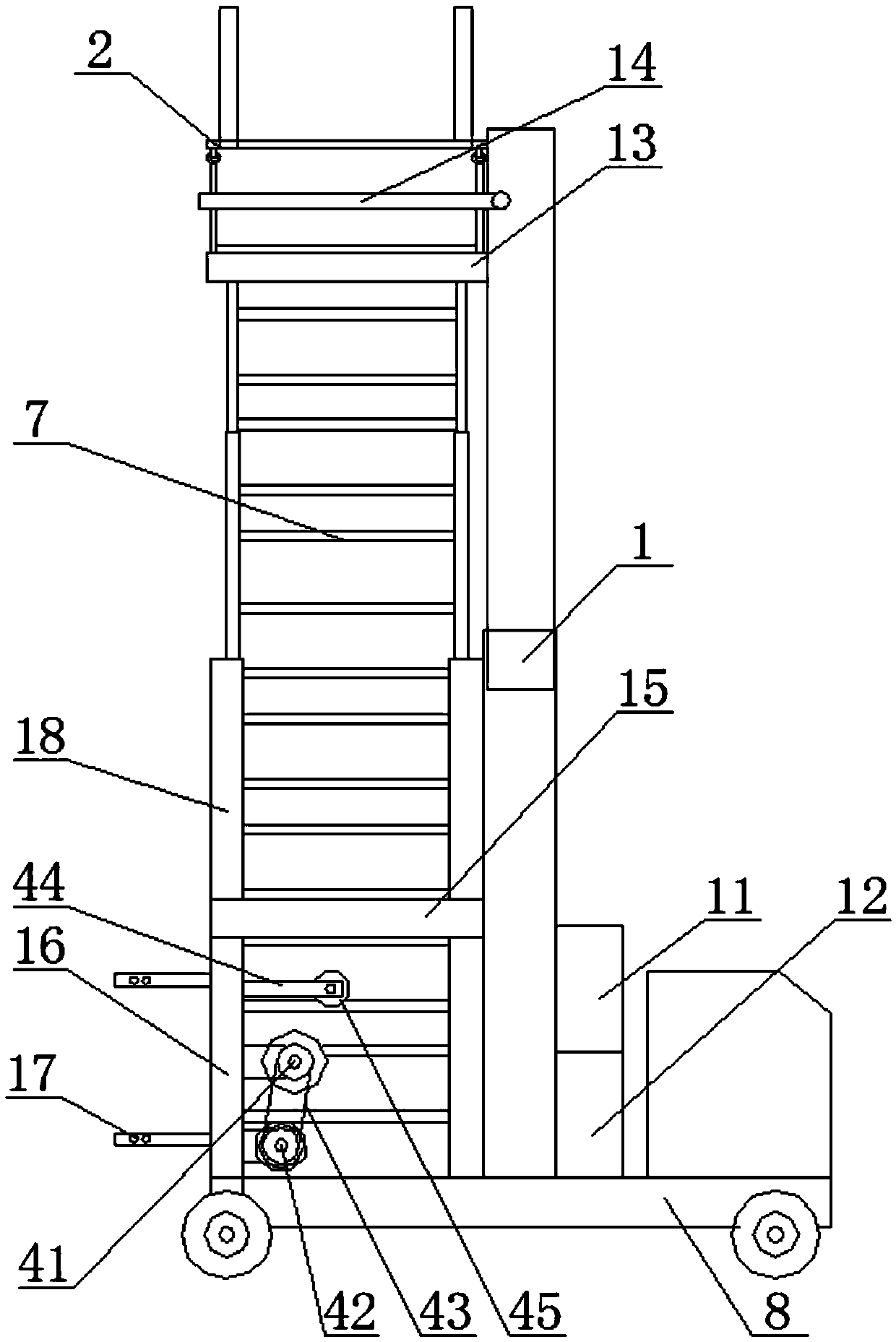

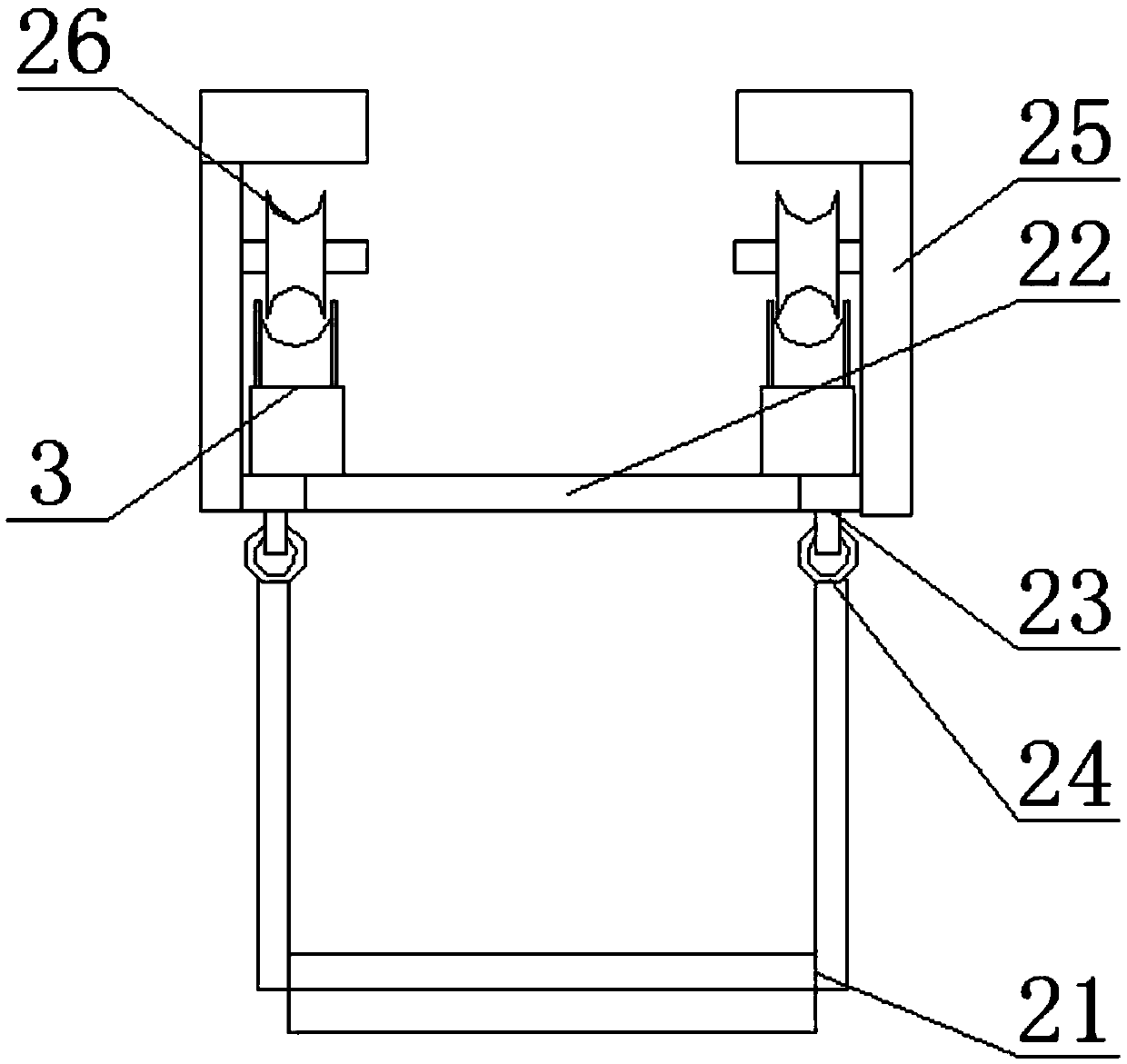

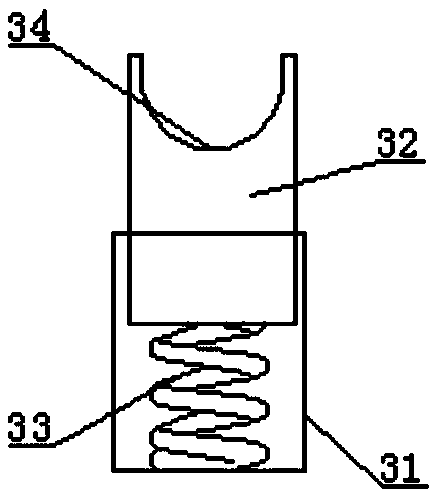

[0030] An aerial work platform for line construction, comprising a supporting frame and a vertical lifting platform 1 installed on the supporting frame, an electrical control unit 11 and a liquid injection pump 12 are arranged at the bottom of the vertical lifting platform 1 for controlling the vertical lifting platform 1 lift. The top of the vertical lifting platform 1 is provided with a first platen 13 and a clamping rod 14, and the aerial work vehicle 2 is arranged on the first platen 13, and the aerial work vehicle 2 includes a vehicle frame 21, and the vehicle frame 21 The clamping rod 14 is detachably connected with the vertical lifting platform 1. During the lifting process of the vertical lifting platform 1, the clamping rod 14 fixes the vehicle frame 21 on the first platen 13 by fastening bolts to prevent the vehicle frame 21 from the first platform 13. Slide down on the platform 13, after the vertical lift platform 1 is adjusted to the required height, the vehicle fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com