Electric porcelain brown glaze trademark glaze and preparation method thereof

An electric porcelain brown and trademark technology, applied in the field of glaze, can solve the problems of edge melting, weak binding force, blurred logo, etc., achieve good lubrication effect, not easy to dry, and improve the effect of stamping strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An electric porcelain brown glaze trademark glaze is made from the following raw materials in parts by weight: 8 parts of cobalt oxide, 2 parts of Dongsheng soil, 10 parts of 1.6%-2.4% sodium carboxymethyl cellulose solution, and 10 parts of glycerin.

[0042] The specific preparation method of the electric porcelain brown glaze trademark glaze of the present embodiment is as follows:

[0043] (1) Take 8 parts of cobalt oxide, 2 parts of Dongsheng soil, 10 parts of 1.6%-2.4% sodium carboxymethylcellulose solution, and 10 parts of glycerol, and mix the above-mentioned components;

[0044] (2) Carry out ball milling to the raw material mixed in step 1, adopt one-time feeding, and make material: ball: water=1:2:1.2, the fineness of ball milling is controlled as 360 mesh sieve surplus is 0;

[0045] (3) The components after ball milling in step 2 can be used after drying.

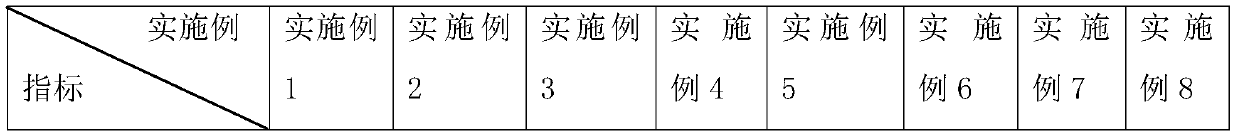

[0046] Table 1

[0047]

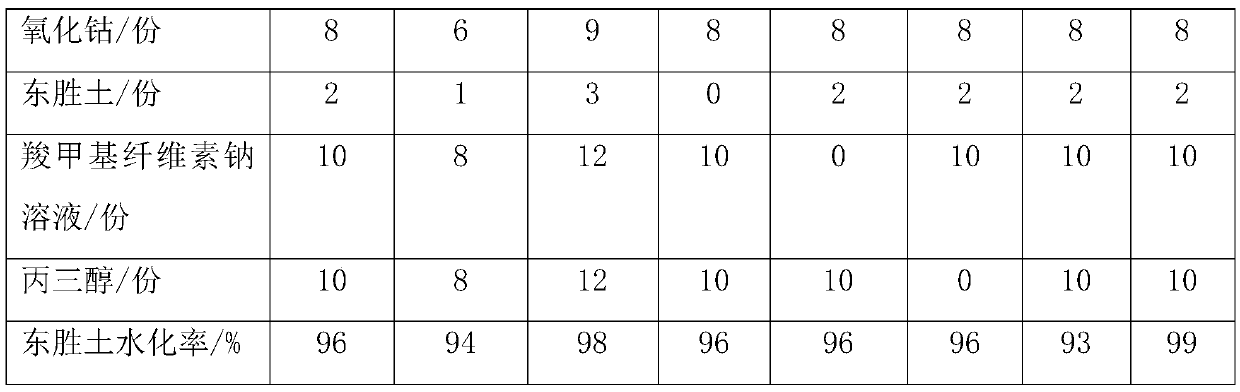

[0048]

[0049] Use the trademark glazes prepared in the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com