A kind of early-strength antifreeze agent for liquid concrete and preparation method thereof

A technology for concrete and antifreeze, applied in the field of building material admixtures, can solve the problems of affecting construction progress and project quality, freezing by cold, manpower consumption, etc., achieving good antifreezing effect, improving early strength, and obvious antifreezing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

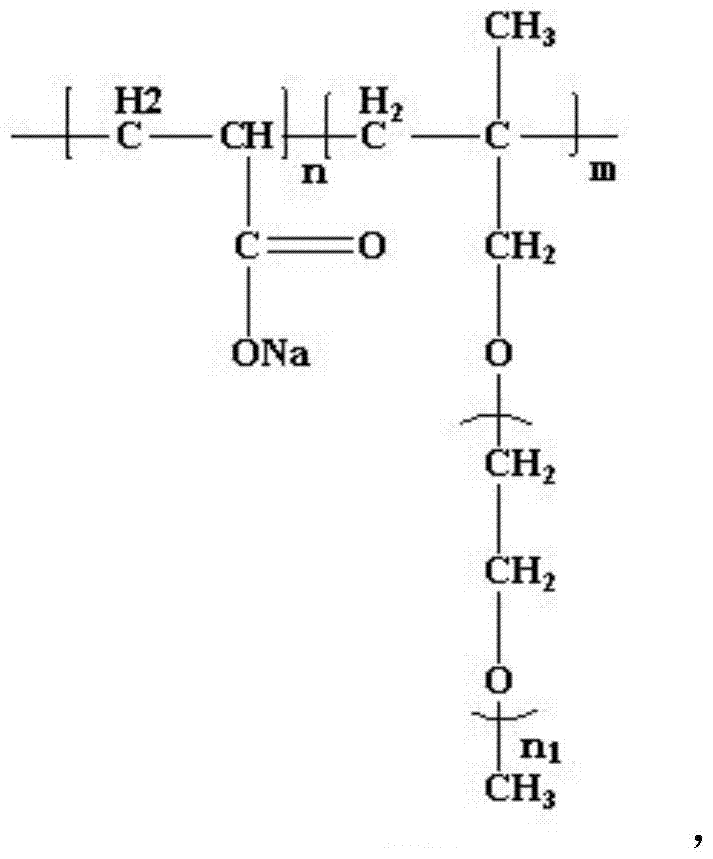

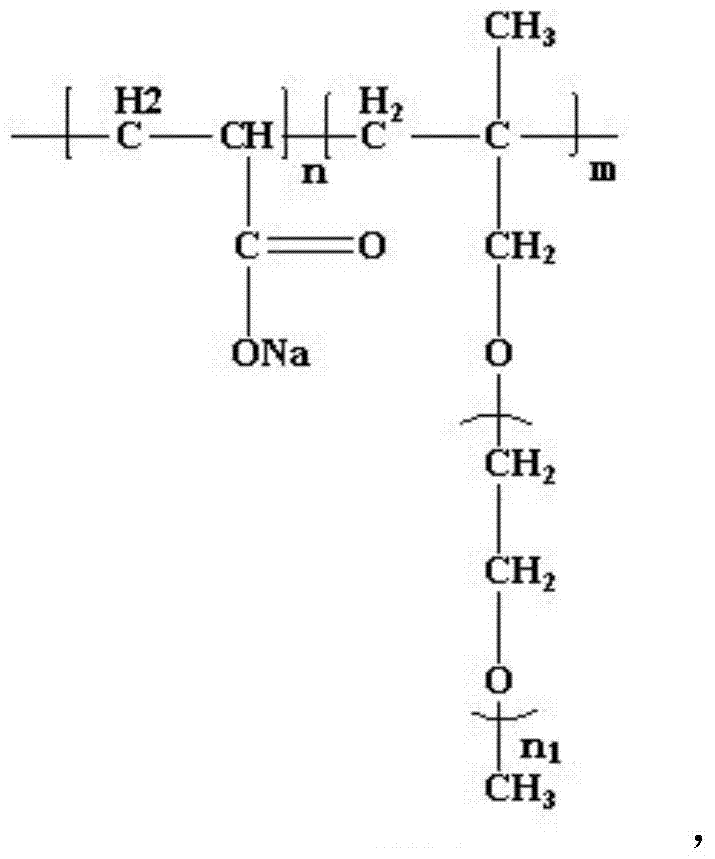

Method used

Image

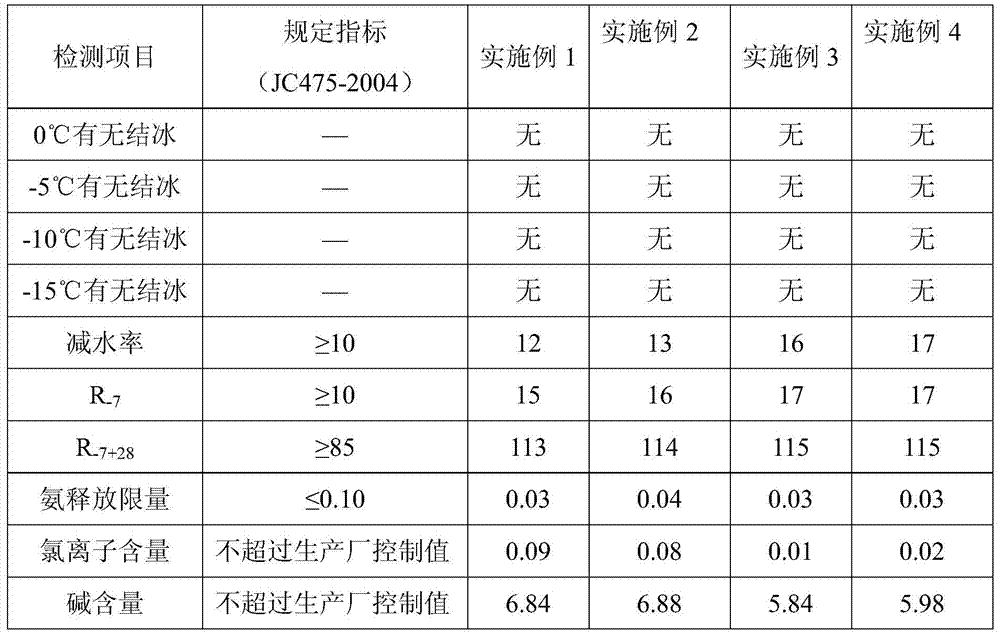

Examples

Embodiment 1

[0034] A liquid concrete early-strength antifreeze, in parts by weight, its raw materials are composed of the following components: monoethanol diisopropanolamine: 2.0 parts, sodium thiosulfate: 5.0 parts, diethylene glycol: 3.0 parts, nitrous acid Sodium: 5.0 parts, sodium lauroyl glutamate: 0.05 parts, di(hydrogenated tallow) phthalic acid amide: 0.05 parts, water: 66.90 parts, polycarboxylate superplasticizer: 18 parts.

[0035] Its preparation method is as follows:

[0036] (1) Mix polycarboxylate high-performance water reducer with water, and stir for 1 to 5 minutes;

[0037] (2) Add sodium thiosulfate, sodium nitrite and air-entraining agent successively to the material of step (1), after adding, stir for 5-10min;

[0038] (3) Add organic alcohol amine, low molecular weight alcohol and solubilizer to the material in step (2), and stir for 5-10 minutes to obtain the liquid concrete early-strength antifreeze agent.

Embodiment 2

[0040] A liquid concrete early-strength antifreeze, in parts by weight, its raw materials are composed of the following components: diethanolamine: 2.0 parts, sodium thiosulfate: 5.0 parts, propylene glycol: 3.0 parts, sodium nitrite: 5.0 parts, lauroyl Sodium phosphate: 0.05 parts, di(hydrogenated tallow) phthalic acid amide: 0.05 parts, water: 66.9 parts, polycarboxylate high-performance water reducer: 18.0 parts.

[0041] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0043] A liquid concrete early-strength antifreeze, in parts by weight, its raw materials are composed of the following components: diethanol monoisopropanolamine: 2.0 parts, sodium thiosulfate: 5.0 parts, diethylene glycol: 3.0 parts, nitrous acid Sodium: 5.0 parts, sodium lauroyl glutamate: 0.05 parts, di(hydrogenated tallow) phthalic acid amide: 0.05 parts, water: 64.9 parts, polycarboxylate superplasticizer: 20.0 parts.

[0044] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com