Preparation method and application of guar-gum-containing coating material

A technology of wrapping materials and guar gum, which is applied in the direction of application, layered/coated fertilizers, fertilizer mixtures, etc., can solve the problems of low fertilizer utilization efficiency and poor controlled release effect of fertilizers, and is conducive to popularization and application and health promotion The effect of moderate growth and controlled release rate of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

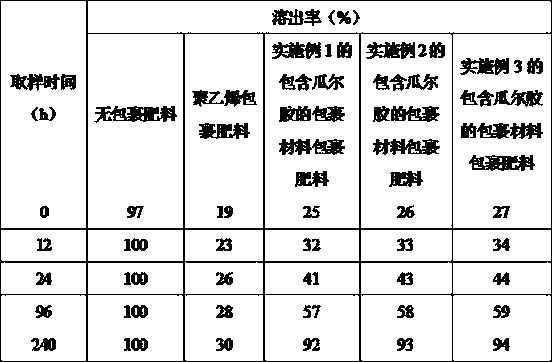

Examples

Embodiment 1

[0024] A preparation method for a wrapping material comprising guar gum, comprising the following steps:

[0025] S1: Warm up the guar gum with 40 parts by weight to 63° C., adjust the pH value of the guar gum to 11.3, and prepare guar gum A;

[0026] S2: Adding 4 parts by weight of polyaluminum sulfate and 1 part of magnesium oxide to the guar gum A prepared in step S1, reacted for 90 minutes at 300 r / min, and added 2 parts by weight of potassium hypochlorite, 1 part after the temperature was raised to 70 ° C. 1 part of glutaraldehyde, reacted at 400r / min for 60min, cooled to 55°C, and added parts by weight of 1 part of zinc sulfate, 1 part of potassium polyacrylate, and 1 part of humic acid, and reacted at 200r / min for 80min to obtain guar Glue B;

[0027] S3: Add 8 parts of diatomite, 8 parts of kaolin, 6 parts of peat, 2 parts of ammonium tripolyphosphate powder, 2 parts of ammonium nitrate powder, and 200 parts of water to the guar gum B prepared in step S2 and mix evenl...

Embodiment 2

[0029] A preparation method for a wrapping material comprising guar gum, comprising the following steps:

[0030] S1: Warming up 60 parts by weight of guar gum to a temperature of 64° C., adjusting the pH value of the guar gum to 11.5 to obtain guar gum A;

[0031] S2: Add 6 parts by weight of polyaluminum sulfate and 2 parts of magnesium oxide to the guar gum A prepared in step S1, react for 70 minutes at 400 r / min, and add 3 parts by weight of potassium hypochlorite, 2 parts after the temperature is raised to 72 ° C. Parts of glutaraldehyde, reacted at 500r / min for 50min, cooled to 60°C, added parts by weight of 2 parts of zinc sulfate, 1.5 parts of potassium polyacrylate, and 1.5 parts of humic acid, and reacted at 300r / min for 70min to obtain guar Glue B;

[0032] S3: Add 12 parts of diatomite, 12 parts of kaolin, 10 parts of peat, 6 parts of ammonium tripolyphosphate powder, 6 parts of ammonium nitrate powder, and 600 parts of water to the guar gum B prepared in step S2 ...

Embodiment 3

[0034] A preparation method for a wrapping material comprising guar gum, comprising the following steps:

[0035] S1: Warm up 50 parts by weight of guar gum to a temperature of 64° C., adjust the pH value of the guar gum to 11.4, and obtain guar gum A;

[0036] S2: Add 5 parts by weight of polyaluminum sulfate and 2 parts of magnesium oxide to the guar gum A prepared in step S1, react at 350r / min for 80min, and add 3 parts by weight of potassium hypochlorite, 2 parts after the temperature is raised to 72°C. Parts of glutaraldehyde, reacted at 450r / min for 55min, cooled to 58°C, added parts by weight of 2 parts of zinc sulfate, 1.5 parts of potassium polyacrylate, and 1.5 parts of humic acid, and reacted at 250r / min for 75min to obtain guar Glue B;

[0037] S3: Add 10 parts of diatomite, 10 parts of kaolin, 8 parts of peat, 4 parts of ammonium tripolyphosphate powder, 4 parts of ammonium nitrate powder, and 400 parts of water to the guar gum B prepared in step S2 and mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com