Novel skid-mounted equipment for removing hydrogen sulfide in natural gas

A technology of natural gas and hydrogen sulfide, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of high operating cost, large area and complex structure, and achieve the effect of simplifying the process, reducing operating cost, and facilitating transportation and relocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

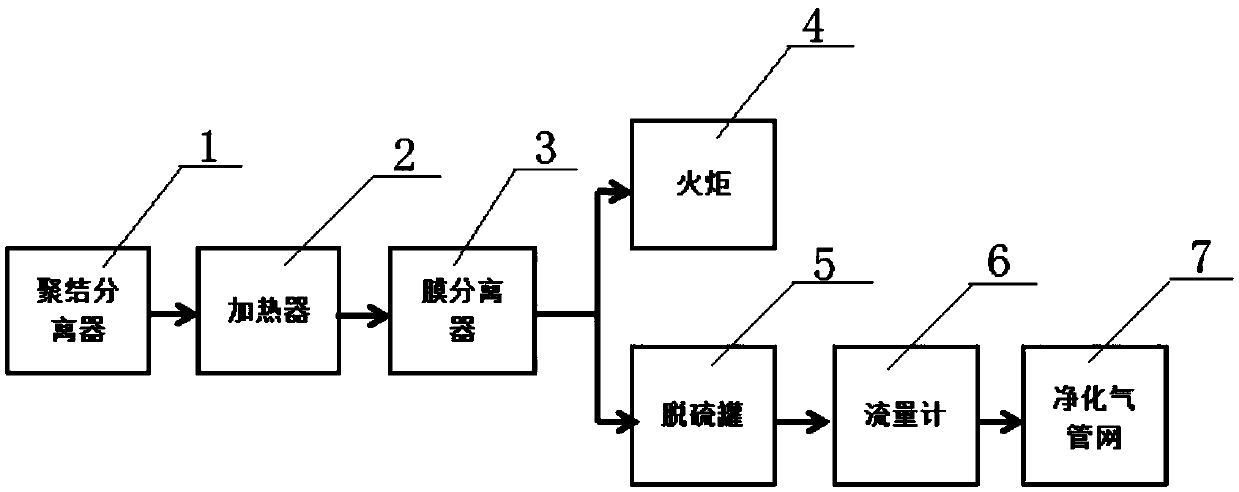

[0015] like figure 1 As shown, the present invention is a novel skid-mounted equipment for removing hydrogen sulfide in natural gas, including a coalescence separator 1 for separating liquid droplets and solids above 5um, so as to realize reheating of natural gas and ensure that the gas temperature is higher than that of water, Heater 2 with hydrocarbon dew point temperature, membrane separator 3 for rough separation of hydrogen sulfide in natural gas, torch 4 for venting combustion or centralized treatment of high-sulfur gas, and re-adsorption and desorption of a small amount of hydrogen sulfide remaining in natural gas The desulfurization tank 5, the flowmeter 6 to monitor the throughput of the treated natural gas, and the purified gas pipeline network 7 to transport the natural gas that meets the standard. The coalescer 1 is provided with a differential pressure gauge. The natural gas outlet at the bottom of the desulfurization tank 5 is provided with a dust filter.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com