Compound biodiesel and preparation method thereof

A biodiesel, composite technology, applied in the field of fatty oil, to achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

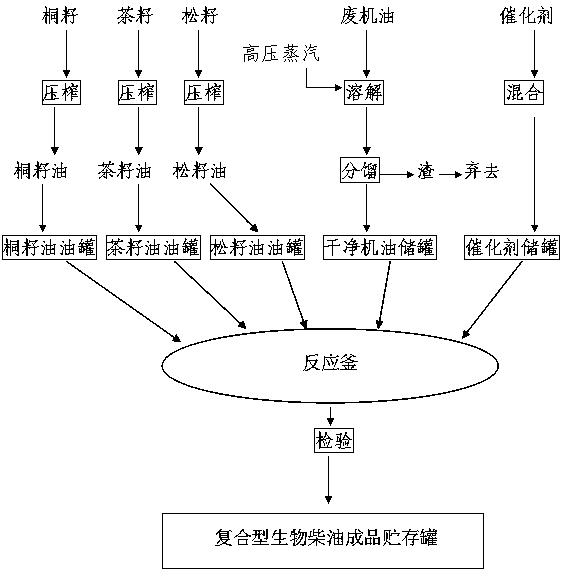

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares the mixed biodiesel of the present invention:

[0025] Take fresh tung seeds, tea seeds, and pine nuts and dry and dehydrate them separately to obtain dried tung seeds, tea seeds, and pine nuts, which are crushed to a fineness of 100 mesh, heated to 65°C, and pressed to obtain tung seed oil and tea seeds respectively Oil and pine nut oil are put into oil tanks for standby; waste engine oil is put into a dissolving container, and steam with a pressure of 80-100MPa is introduced to make it completely dissolved; after that, the oil is sent to a fractionator for fractionation, with a low boiling point The remaining part is the pure engine oil, put it into the engine oil tank, and set aside; discard the sludge residue from the fractionator; take 10L of tung seed oil, 10L of tea seed oil, 10L of pine nut oil and 55L of pure engine oil, and add 15L of catalyst, The catalyst is a mixture of methyl ether, dimethyl ether or acetone according to the volume ra...

Embodiment 2

[0026] Embodiment 2 prepares the mixed biodiesel of the present invention

[0027] The preparation process is the same as in Example 1, and the volume ratio of raw materials is: 10L of tung seed oil, 10L of tea seed oil, 10L of pine nut oil and 60L of pure engine oil, and 10L of catalyst is added. The catalyst is a mixture of methyl ether, dimethyl ether or acetone in a volume ratio of 2:3:5. eventually get to 0 # Diesel standard compound biodiesel finished product 100L.

Embodiment 3

[0028] Embodiment 3 prepares the mixed biodiesel of the present invention

[0029] The preparation process is the same as in Example 1, and the volume ratio of raw materials is: 10L of tung seed oil, 10L of tea seed oil, 10L of pine nut oil and 65L of pure engine oil, and 5L of catalyst is added. The catalyst is a mixture of methyl ether, dimethyl ether or acetone in a volume ratio of 3:5:2. eventually get to 0 # Diesel standard compound biodiesel finished product 100L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com