Superhydrophobic coating and preparation method thereof

A super-hydrophobic coating and ultrasonic dispersion technology, which is applied in the direction of coating, hydrophobic agent addition, inorganic compound addition, etc., can solve the problems of harsh preparation conditions and cumbersome preparation steps of super-hydrophobic materials, and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

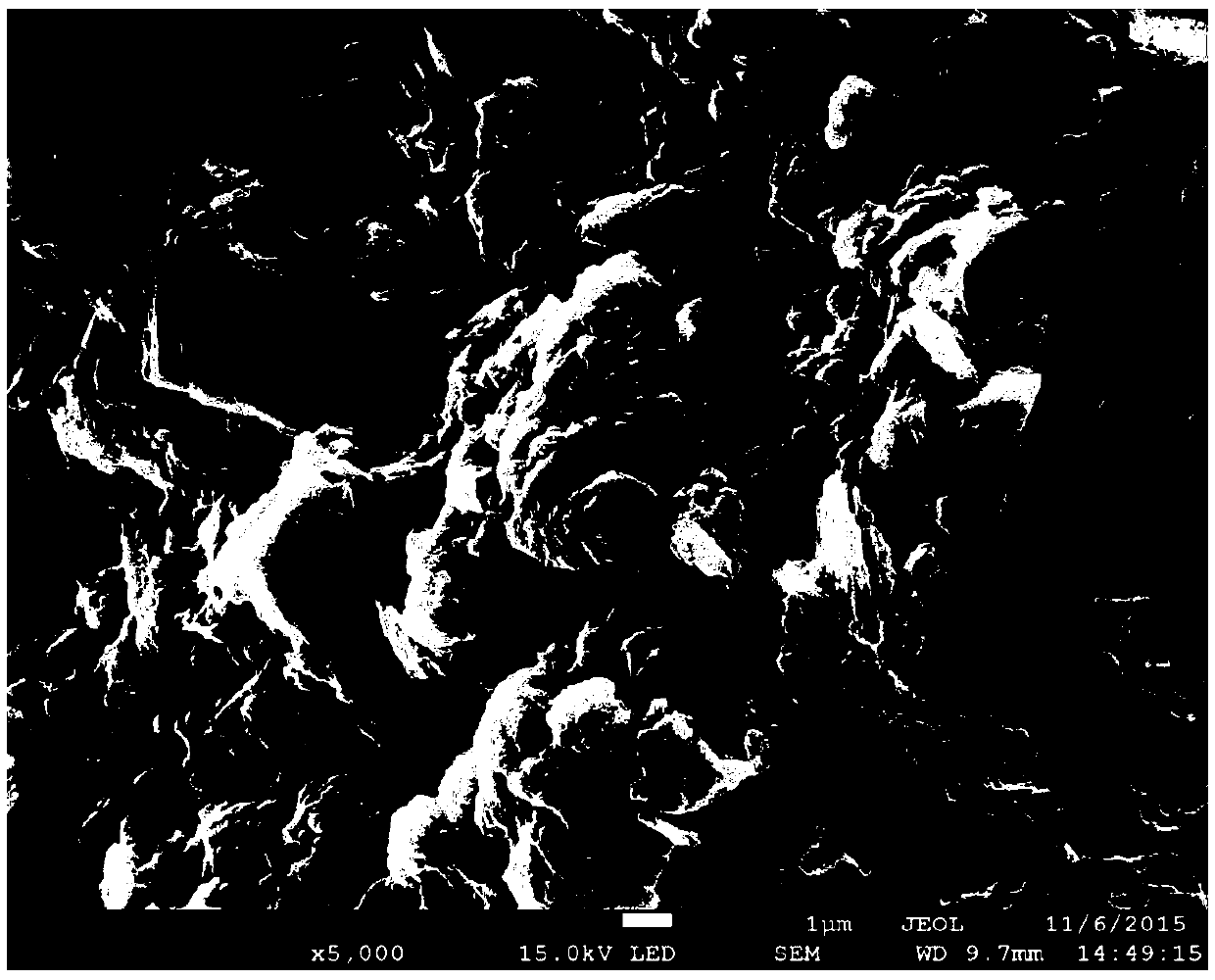

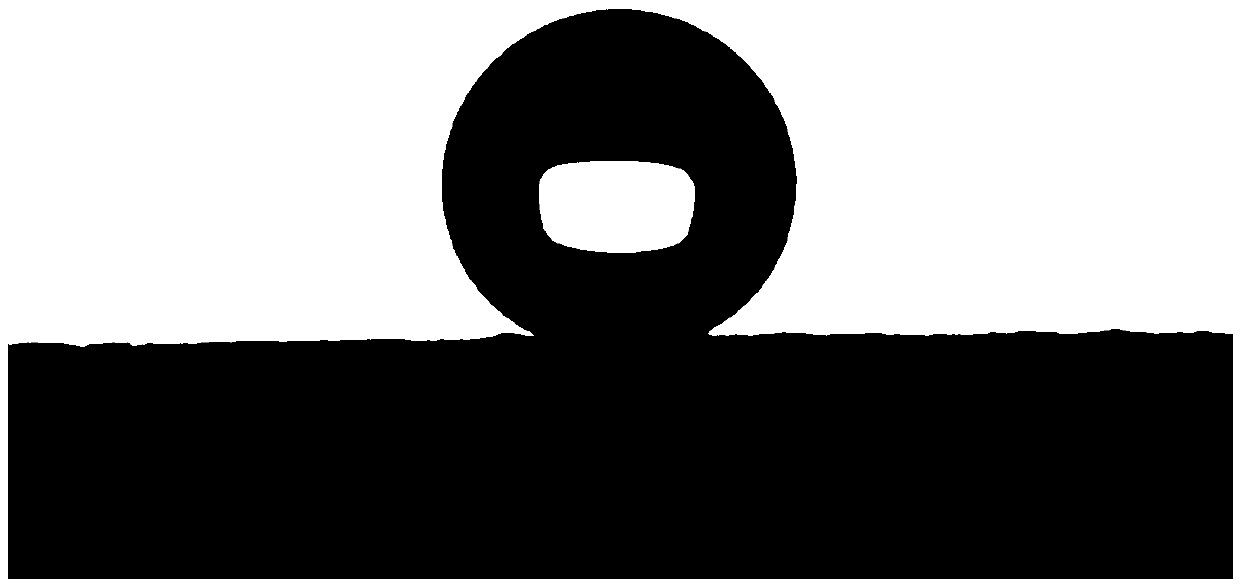

[0020] Weigh 2 g of natural clinoptilolite and add it to 50 g of ethanol, ultrasonically disperse for 30 min, then add 0.17 g of perfluorodecyltrichlorosilane, and continue ultrasonicating for 10 min to obtain a dispersion. After soaking for 3 minutes, take it out and dry it at 60° C. for 30 minutes, immerse the dried filter paper in the dispersion liquid again, take it out after 3 minutes and dry it again for 30 minutes, and a superhydrophobic coating is formed on the surface of the filter paper. The conditions for the ultrasonic dispersion are that the ultrasonic frequency is 40KHz and the ultrasonic power is 100W. Figure 1 to Figure 2 They are the scanning electron micrograph and the contact angle diagram of the superhydrophobic coating on the surface of the filter paper, respectively. It can be seen from the figure that the hydrophobic coating has a better micro-nano structure and good hydrophobic performance.

Embodiment 2

[0022] Weigh 5g of natural mordenite and add it to 100g of ethanol, ultrasonically disperse for 60min, then add 0.85g of perfluorodecyltrichlorosilane, continue ultrasonicating for 30min to obtain a dispersion, and dip a round filter paper used in the laboratory into the dispersion Take it out after 5 minutes and dry it at 70°C for 30 minutes, immerse the dried filter paper in the dispersion liquid again, take it out after 5 minutes and dry it again for 30 minutes, immerse the dried filter paper in the dispersion liquid again, take it out after 3 minutes and finally After drying for 45min, a superhydrophobic coating is formed on the surface of the filter paper. The conditions for the ultrasonic dispersion are that the ultrasonic frequency is 20KHz, and the ultrasonic power is 60W.

Embodiment 3

[0024] Weigh 3g of natural calcium zeolite and add it to 60g of ethanol, ultrasonically disperse for 45min, then add 0.45g of perfluorodecyltrichlorosilane, continue to ultrasonically for 45min to obtain a dispersion, and dip a conventional circular filter paper in the laboratory into the dispersion After 4 minutes, it was taken out and dried at 65° C. for 45 minutes. The dried filter paper was immersed in the dispersion again, taken out after 4 minutes and dried again for 45 minutes. A superhydrophobic coating was formed on the surface of the filter paper. The conditions for the ultrasonic dispersion are that the ultrasonic frequency is 20KHz, and the ultrasonic power is 60W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com