Coal mining face supporting robot

A technology of coal mining face and robot, applied in mining equipment, earth square drilling, mine roof support, etc., can solve the problems of no sensor detection support system, slow response speed, low control accuracy, etc., and achieve convenient equipment connection , Improve reliability and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

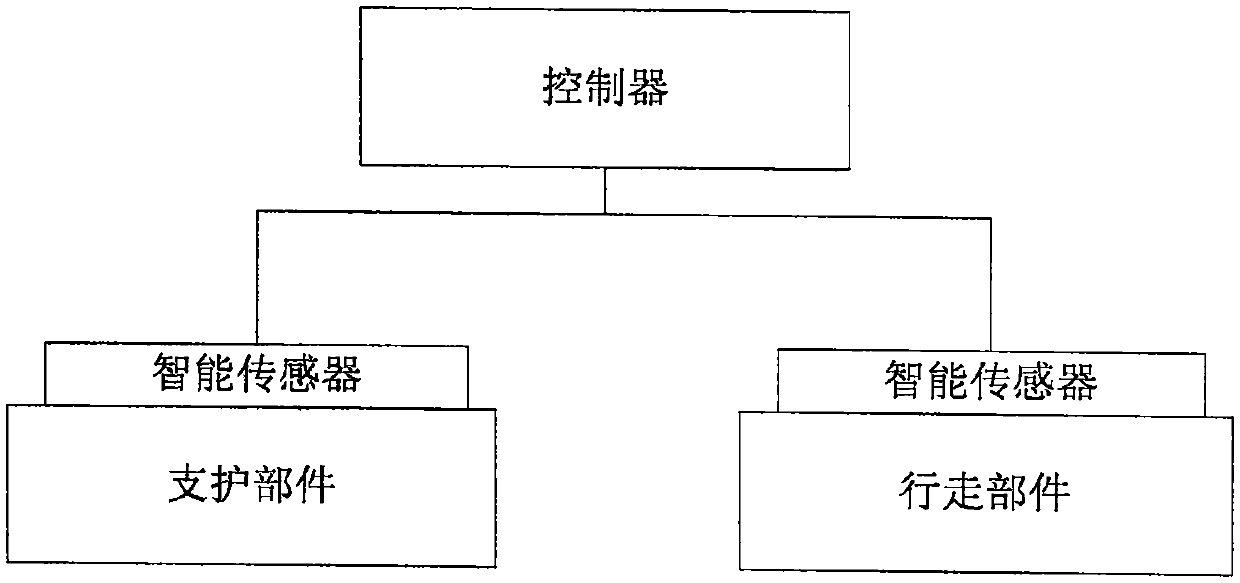

[0034] Attached below figure 1The present invention is further described in detail. A coal mining face support robot includes a support component, a walking component, a controller and various types of intelligent sensors. The support component, the controller and the actuator control the support component to realize the lifting of the support robot, and the support pressure sensor monitors the pressure of the support to effectively support the roof of the coal mining face. The walking part, the controller and the actuator control the walking part to realize the free migration of the support robot, and the walking step sensor monitors the size of the migration step, and performs the free migration and precise control of the step distance of the support robot in the front, rear, left, and right directions.

[0035] The controller is installed on the main part of the support robot, and according to various intelligent sensor data collected, realizes attitude perception, center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com