An emergency release device for a gas cabinet

A gas tank and emergency technology, which is applied in the field of emergency venting devices for gas tanks, can solve problems such as gas leakage, easy corrosion, hidden safety hazards, etc., and achieve the effects of saving man-hours and costs, strengthening sealing effect, and facilitating coordination and positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

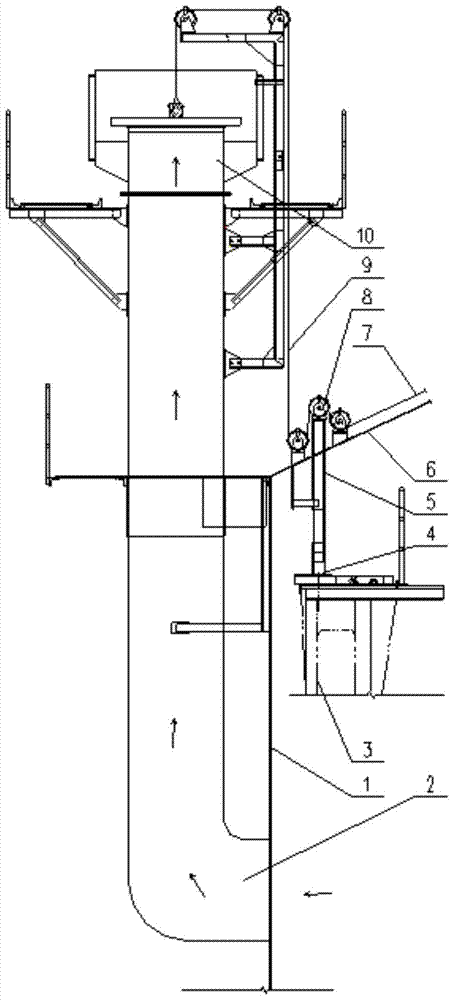

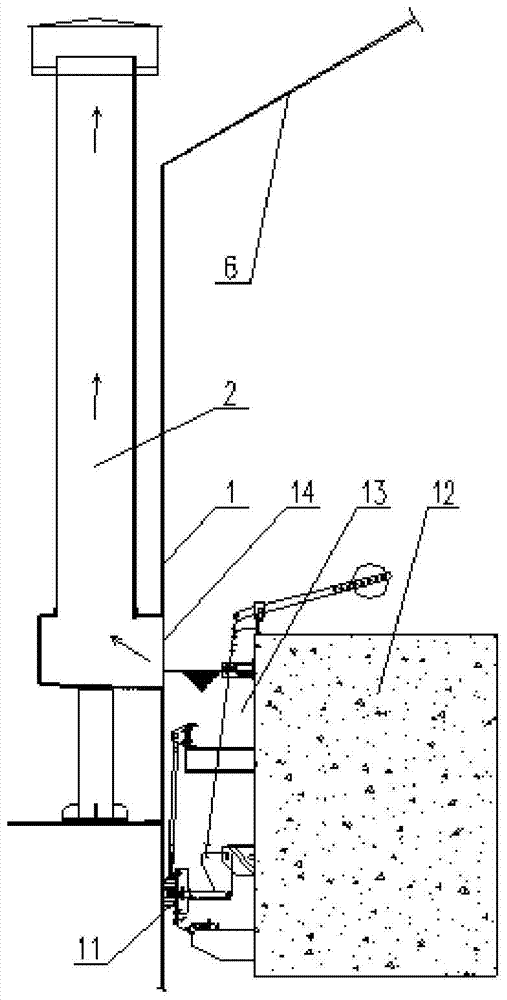

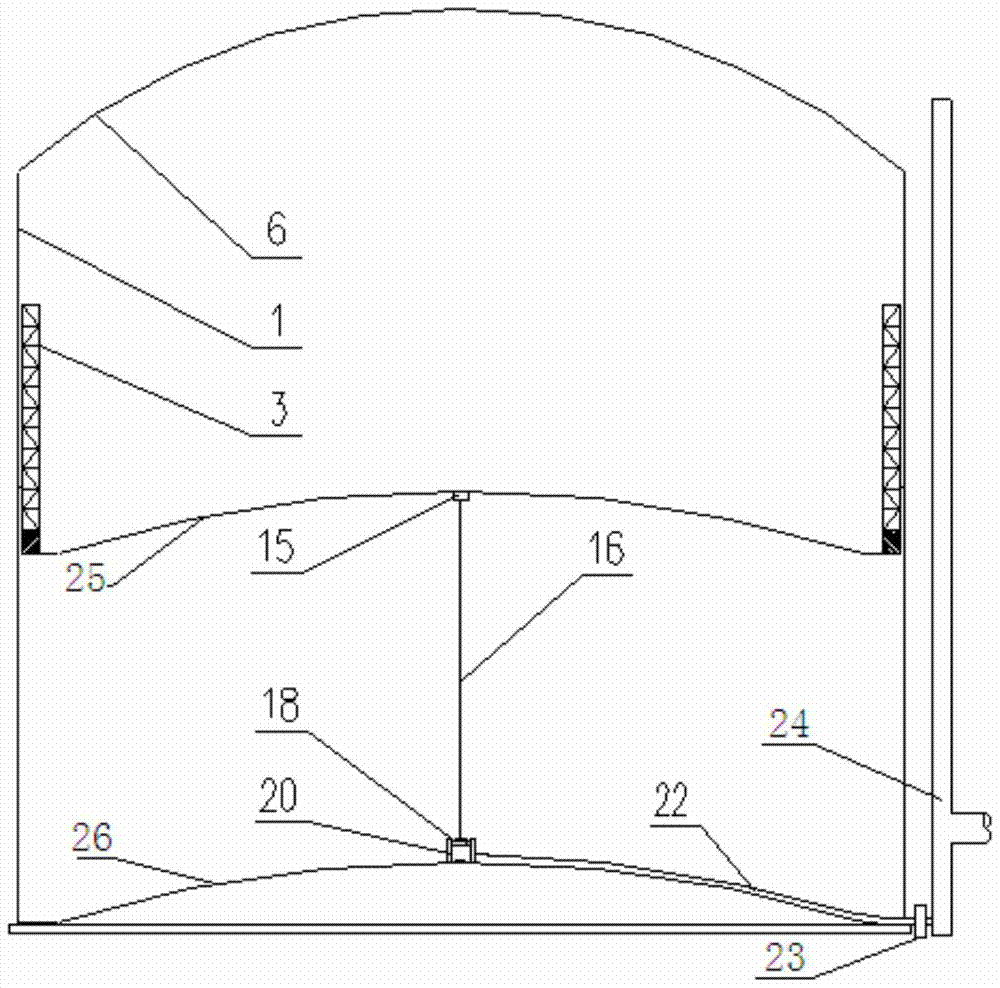

[0033] Such as image 3 and Figure 4 As shown, an emergency relief device for a gas cabinet includes a steel rope 16, a relief valve, a first relief pipe 22 and a safety relief pipe 24. The relief valve is composed of a valve seat 20 and a valve cover 18, and the valve seat 20 is provided with an opening at the top The valve cover 18 can completely cover and seal the top opening of the valve seat 20, the valve seat 20 is fixed on the cabinet bottom plate 26, the two ends of the steel rope 16 are respectively connected with the piston plate 25 and the valve cover 18, and the steel rope 16 The effective length is equal to the stroke of the piston, and one end of the first relief pipe 22 communicates with the valve seat 20, and the other end passes through the gas tank and communicates with the safety relief pipe 24. Such as image 3 As shown, under no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com