Parallel-type rock temperature, seepage and stress coupling triaxial rheometer

A triaxial rheological and parallel technology, applied in the field of geotechnical engineering test instruments and underground engineering, can solve the problems of large size of the triaxial pressure chamber, chemical coupling rheology, no breakthrough, etc., to save test costs and system versatility. Good, shorten the effect of the test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

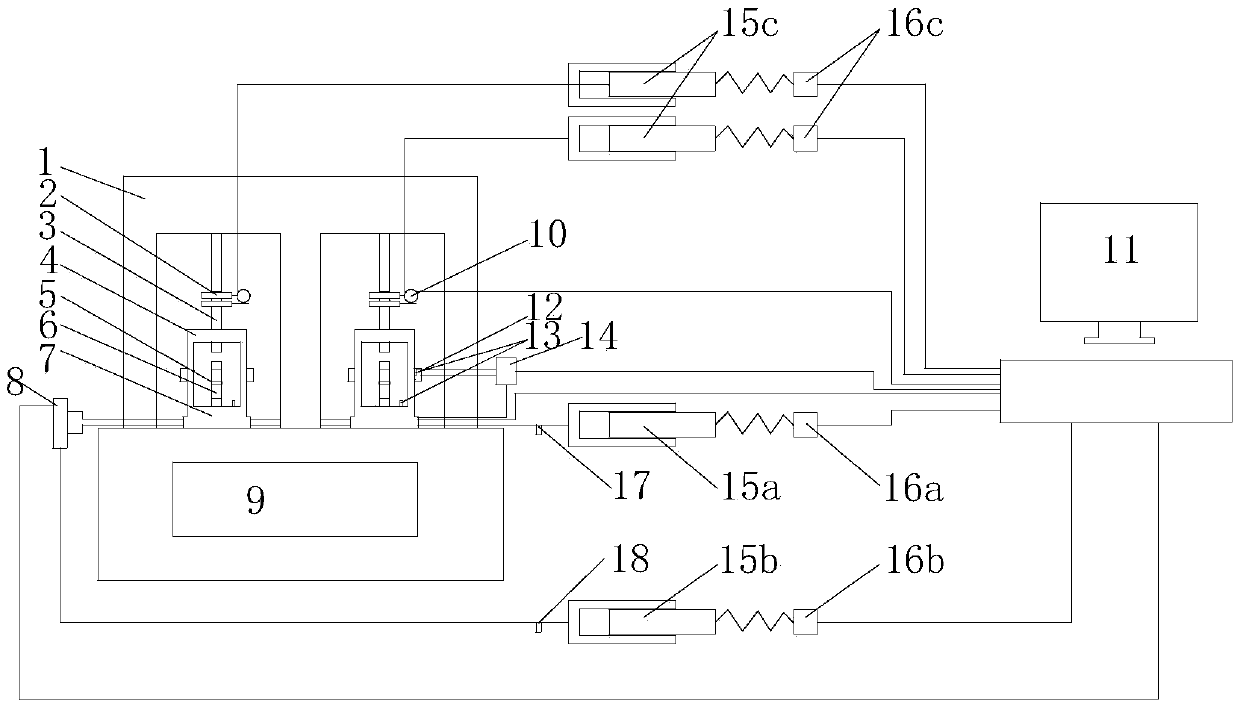

[0027] according to figure 1 , the test instrument includes: special triaxial pressure chamber 4, axial pressure servo control system (by axial pressure sensor 2, ball screw drive wheel 9, control and data acquisition system 11, axial pressure servo loading system 15c, axial pressure servo motor 16c), confining pressure servo control system (composed of control and data acquisition system 11, confining pressure servo loading system 15a, confining pressure servo motor 16a, confining pressure sensor 17), pore pressure servo control system (composed of upper pore pressure Pressure sensor 8, control and data acquisition system 11, hole pressure servo loading system 15b, hole pressure servo motor 16b, lower hole pressure pressure sensor 18), temperature control system (composed of control and data acquisition system 11, electric heating coil 12, Temperature sensor 13, temperature controller 14 is made up of), control and data acquisition system 11 etc. parts are formed, and this in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com